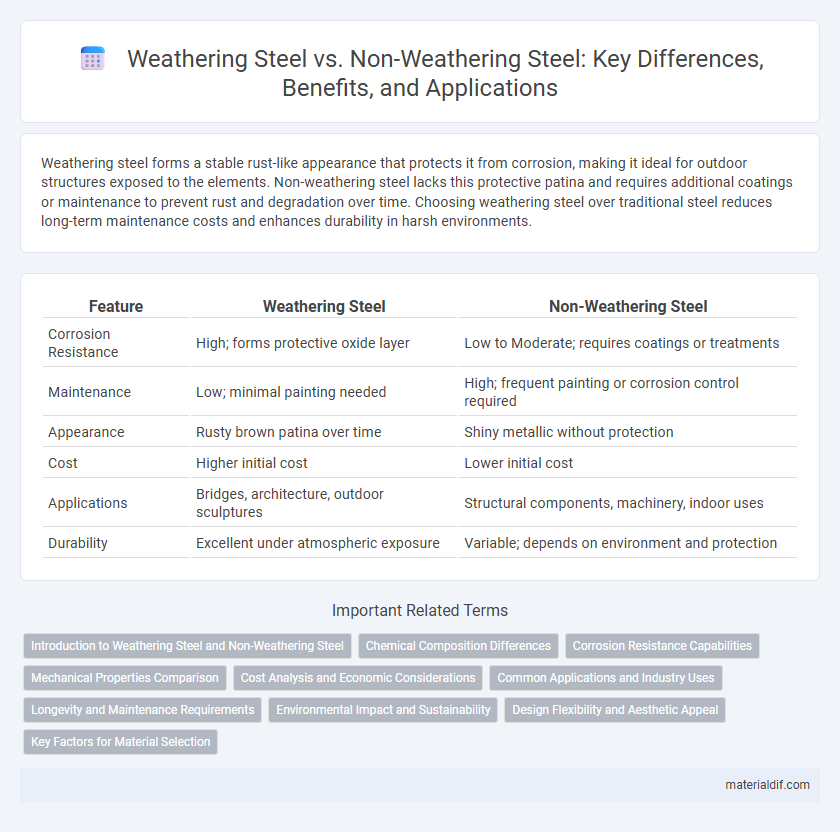

Weathering steel forms a stable rust-like appearance that protects it from corrosion, making it ideal for outdoor structures exposed to the elements. Non-weathering steel lacks this protective patina and requires additional coatings or maintenance to prevent rust and degradation over time. Choosing weathering steel over traditional steel reduces long-term maintenance costs and enhances durability in harsh environments.

Table of Comparison

| Feature | Weathering Steel | Non-Weathering Steel |

|---|---|---|

| Corrosion Resistance | High; forms protective oxide layer | Low to Moderate; requires coatings or treatments |

| Maintenance | Low; minimal painting needed | High; frequent painting or corrosion control required |

| Appearance | Rusty brown patina over time | Shiny metallic without protection |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Bridges, architecture, outdoor sculptures | Structural components, machinery, indoor uses |

| Durability | Excellent under atmospheric exposure | Variable; depends on environment and protection |

Introduction to Weathering Steel and Non-Weathering Steel

Weathering steel, also known as COR-TEN steel, features a protective oxide layer that forms when exposed to weather, enhancing corrosion resistance without the need for painting. Non-weathering steel lacks this self-protective oxide layer, making it more susceptible to rust and requiring regular maintenance or coatings for durability. The inherent properties of weathering steel make it ideal for outdoor structures, bridges, and sculptures where low maintenance and long-term durability are critical.

Chemical Composition Differences

Weathering steel contains higher amounts of copper, chromium, nickel, and phosphorus compared to non-weathering steel, which enhances its corrosion resistance by forming a protective oxide layer. Non-weathering steel typically has a simpler chemical composition primarily composed of iron and carbon, lacking these alloying elements that provide durability against atmospheric conditions. The specific chemical additives in weathering steel reduce maintenance costs and increase lifespan in outdoor structural applications.

Corrosion Resistance Capabilities

Weathering steel, also known as corten steel, forms a stable oxide layer that protects the metal from further corrosion, making it highly resistant to atmospheric conditions without the need for protective coatings. Non-weathering steel lacks this protective patina and corrodes more rapidly when exposed to moisture and oxygen, requiring additional treatments like painting or galvanization to enhance its corrosion resistance. The superior corrosion resistance capabilities of weathering steel reduce maintenance costs and extend the lifespan in outdoor and industrial applications.

Mechanical Properties Comparison

Weathering steel exhibits enhanced mechanical properties such as higher tensile strength and improved toughness compared to non-weathering steel, attributed to its unique alloy composition with copper, chromium, and nickel. The corrosion resistance of weathering steel leads to reduced maintenance costs and prolonged structural integrity, while non-weathering steel typically requires protective coatings to prevent degradation. Both types share similar yield strength ranges, but weathering steel's superior ductility and fatigue resistance make it more suitable for outdoor applications exposed to variable weather conditions.

Cost Analysis and Economic Considerations

Weathering steel offers significant cost savings over non-weathering steel by reducing maintenance expenses due to its corrosion-resistant properties, eliminating the need for protective coatings and frequent repainting. Initial material costs for weathering steel may be higher, but the long-term economic benefits include lower life-cycle costs and extended service life in outdoor applications. Non-weathering steel incurs additional costs linked to protective treatments and maintenance, making it less economical for structures exposed to harsh weather conditions.

Common Applications and Industry Uses

Weathering steel is commonly used in outdoor structures such as bridges, sculptures, and building facades due to its corrosion resistance and ability to form a protective rust layer, reducing maintenance costs. Non-weathering steel is preferred for applications requiring consistent surface appearance and strength, including automotive components, machinery, and construction frameworks. Industries like construction, infrastructure, and manufacturing select steel types based on environmental exposure and durability requirements.

Longevity and Maintenance Requirements

Weathering steel offers superior longevity due to its protective rust patina that reduces corrosion, unlike non-weathering steel which requires regular maintenance and protective coatings to prevent rust. The self-healing oxide layer on weathering steel eliminates frequent repainting, substantially lowering maintenance costs over time. Non-weathering steel, exposed to harsh environments, demands consistent upkeep to maintain structural integrity and aesthetic appearance.

Environmental Impact and Sustainability

Weathering steel forms a stable rust layer that reduces corrosion without paint, significantly lowering maintenance frequency and associated environmental waste compared to non-weathering steel. Non-weathering steel requires regular coatings and anti-corrosive treatments, contributing to higher consumption of volatile organic compounds (VOCs) and hazardous chemicals. The sustainable advantage of weathering steel lies in its longer lifespan and reduced need for resource-intensive protective measures, minimizing its ecological footprint in construction and infrastructure projects.

Design Flexibility and Aesthetic Appeal

Weathering steel offers superior design flexibility with its self-protective oxide layer that develops rich, earthy tones over time, eliminating the need for painting and enabling creative, low-maintenance architectural applications. Non-weathering steel requires protective coatings to prevent corrosion, limiting design options and increasing maintenance costs while providing a more uniform, industrial appearance. The natural patina of weathering steel enhances aesthetic appeal by blending seamlessly into natural environments and urban landscapes, making it a preferred choice for innovative structural and decorative elements.

Key Factors for Material Selection

Weathering steel offers superior corrosion resistance due to its ability to form a stable oxide layer, reducing maintenance costs and extending service life in outdoor applications. Non-weathering steel requires protective coatings to prevent rust, making it suitable for indoor or controlled environments where aesthetic finish or structural strength variations are critical. Key factors in material selection include environmental exposure, maintenance budget, structural requirements, and project lifespan.

Weathering Steel vs Non-Weathering Steel Infographic

materialdif.com

materialdif.com