Weathering steel develops a stable rust-like appearance that protects it from further corrosion, unlike standard steel which requires additional coatings or treatments to prevent rust. This corrosion resistance makes weathering steel ideal for outdoor structures exposed to varying weather conditions, reducing maintenance costs. In contrast, standard steel is more susceptible to rust and degradation when exposed to moisture and environmental elements.

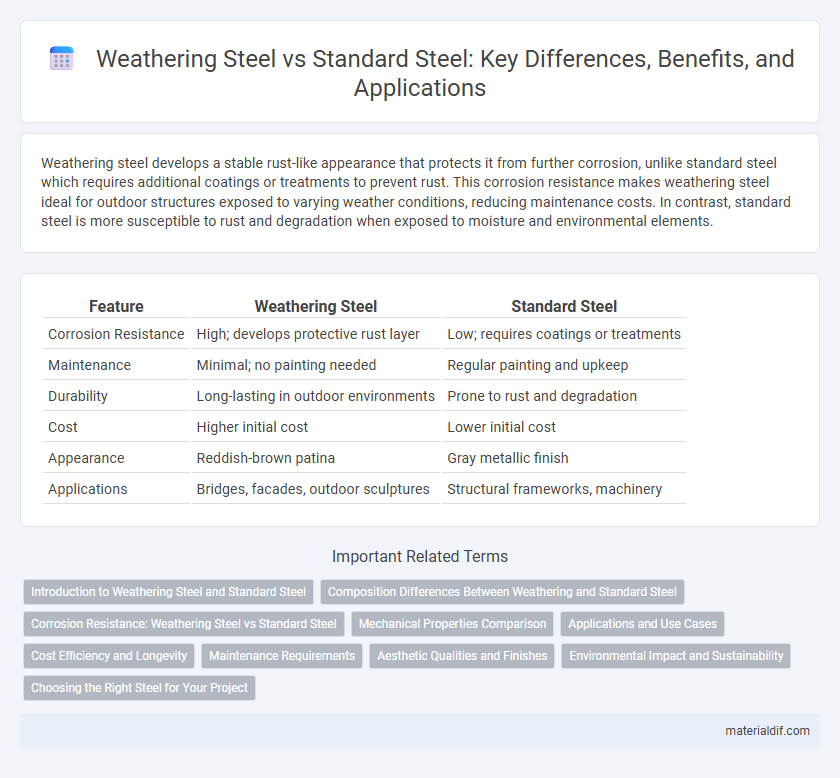

Table of Comparison

| Feature | Weathering Steel | Standard Steel |

|---|---|---|

| Corrosion Resistance | High; develops protective rust layer | Low; requires coatings or treatments |

| Maintenance | Minimal; no painting needed | Regular painting and upkeep |

| Durability | Long-lasting in outdoor environments | Prone to rust and degradation |

| Cost | Higher initial cost | Lower initial cost |

| Appearance | Reddish-brown patina | Gray metallic finish |

| Applications | Bridges, facades, outdoor sculptures | Structural frameworks, machinery |

Introduction to Weathering Steel and Standard Steel

Weathering steel, also known as corten steel, is engineered to form a stable rust-like appearance after exposure to weather, eliminating the need for painting and providing enhanced corrosion resistance. Standard steel, typically carbon steel, lacks this protective oxide layer and requires coatings to prevent rust and corrosion over time. Weathering steel is favored in outdoor structural applications where durability and low maintenance are critical, while standard steel is widely used in construction and manufacturing where direct protection is feasible.

Composition Differences Between Weathering and Standard Steel

Weathering steel, also known as COR-TEN steel, contains higher levels of copper, chromium, nickel, and phosphorus compared to standard steel, which enhances its corrosion resistance by forming a protective rust layer. Standard steel primarily consists of iron and carbon with minimal alloying elements, making it more susceptible to rust and requiring protective coatings. The specific alloy composition in weathering steel reduces the need for painting and maintenance in outdoor applications exposed to atmospheric conditions.

Corrosion Resistance: Weathering Steel vs Standard Steel

Weathering steel exhibits superior corrosion resistance compared to standard steel due to its unique alloy composition, which forms a stable, protective rust layer that adheres tightly to the material surface. This patina inhibits further oxidation, significantly reducing maintenance costs and extending the lifespan of structures exposed to atmospheric conditions. In contrast, standard steel lacks this self-protective layer, making it more susceptible to rust and requiring more frequent protective coatings or treatments to prevent corrosion.

Mechanical Properties Comparison

Weathering steel exhibits enhanced corrosion resistance due to its alloy composition, which includes elements like copper, chromium, and nickel, forming a protective rust layer that increases durability without compromising mechanical strength. Mechanical properties such as tensile strength and yield strength in weathering steel are comparable to standard carbon steel, with typical tensile strength ranging from 490 to 620 MPa and yield strength around 280 to 450 MPa. The improved toughness and resistance to atmospheric corrosion make weathering steel an optimal choice for structural applications exposed to harsh environments, offering extended service life and reduced maintenance costs.

Applications and Use Cases

Weathering steel, known for its corrosion-resistant properties, is widely used in outdoor structures such as bridges, sculptures, and building facades where minimal maintenance is crucial. Standard steel, with its higher flexibility in fabrication and lower initial cost, suits applications including automotive components, machinery, and indoor construction where environmental exposure is limited. Choosing between weathering steel and standard steel depends on factors like exposure to elements, maintenance requirements, and aesthetic preferences in architectural and industrial projects.

Cost Efficiency and Longevity

Weathering steel offers superior cost efficiency compared to standard steel due to its corrosion-resistant alloy composition, which eliminates the need for painting or protective coatings. This material forms a stable rust-like appearance that protects the structural integrity, significantly extending its longevity in outdoor applications without frequent maintenance. Standard steel, while initially less expensive, incurs higher long-term costs from regular upkeep, repainting, and potential premature replacement caused by corrosion damage.

Maintenance Requirements

Weathering steel requires significantly less maintenance compared to standard steel due to its self-protecting oxide layer that prevents rust and corrosion. Standard steel often demands regular painting or coating to avoid deterioration, increasing long-term upkeep costs. The reduced need for surface treatment in weathering steel lowers labor and material expenses, enhancing its suitability for outdoor and industrial applications.

Aesthetic Qualities and Finishes

Weathering steel develops a unique rust-like patina that enhances its aesthetic appeal by providing a natural, textured finish resistant to corrosion without paint. Standard steel typically requires protective coatings to prevent rust, resulting in a smoother, more uniform surface but lacking the distinctive, evolving appearance of weathering steel. The self-protecting oxide layer on weathering steel creates a dynamic visual character favored in architectural and artistic applications.

Environmental Impact and Sustainability

Weathering steel forms a stable rust-like appearance that protects against corrosion, reducing the need for protective coatings and maintenance, thereby lowering environmental impact compared to standard steel. The extended lifespan and reduced need for replacement of weathering steel decrease resource consumption and landfill waste. Standard steel production and frequent maintenance contribute to higher carbon emissions and ecological footprint, making weathering steel a more sustainable choice in construction and infrastructure projects.

Choosing the Right Steel for Your Project

Weathering steel, known for its corrosion-resistant patina, offers superior durability in outdoor environments compared to standard steel, which requires protective coatings to prevent rust. Selecting weathering steel reduces maintenance costs and extends the lifespan of structures exposed to weather, making it ideal for bridges, sculptures, and architectural facades. Standard steel remains a cost-effective choice for indoor projects or applications where controlled environments mitigate corrosion risks.

Weathering Steel vs Standard Steel Infographic

materialdif.com

materialdif.com