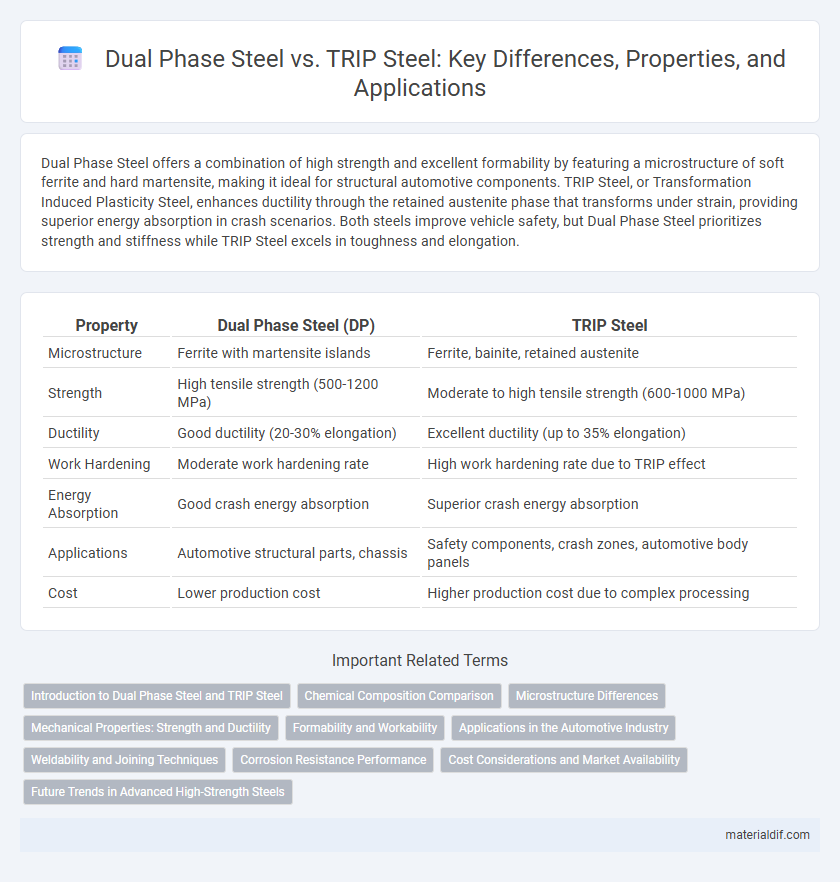

Dual Phase Steel offers a combination of high strength and excellent formability by featuring a microstructure of soft ferrite and hard martensite, making it ideal for structural automotive components. TRIP Steel, or Transformation Induced Plasticity Steel, enhances ductility through the retained austenite phase that transforms under strain, providing superior energy absorption in crash scenarios. Both steels improve vehicle safety, but Dual Phase Steel prioritizes strength and stiffness while TRIP Steel excels in toughness and elongation.

Table of Comparison

| Property | Dual Phase Steel (DP) | TRIP Steel |

|---|---|---|

| Microstructure | Ferrite with martensite islands | Ferrite, bainite, retained austenite |

| Strength | High tensile strength (500-1200 MPa) | Moderate to high tensile strength (600-1000 MPa) |

| Ductility | Good ductility (20-30% elongation) | Excellent ductility (up to 35% elongation) |

| Work Hardening | Moderate work hardening rate | High work hardening rate due to TRIP effect |

| Energy Absorption | Good crash energy absorption | Superior crash energy absorption |

| Applications | Automotive structural parts, chassis | Safety components, crash zones, automotive body panels |

| Cost | Lower production cost | Higher production cost due to complex processing |

Introduction to Dual Phase Steel and TRIP Steel

Dual Phase Steel features a microstructure of martensite dispersed in a ferrite matrix, delivering high strength and good formability, ideal for automotive applications. TRIP Steel, or Transformation-Induced Plasticity steel, contains retained austenite that transforms to martensite under stress, enhancing ductility and energy absorption. Both steels offer advanced mechanical properties but differ in phase transformation mechanisms and resulting performance characteristics.

Chemical Composition Comparison

Dual Phase steel typically contains a higher percentage of manganese (1.2-2.0%) and a lower silicon content (up to 0.5%) compared to TRIP steel, which features manganese levels around 1.5% to 2.0% and elevated silicon content (1.5-2.0%) to stabilize retained austenite. TRIP steel's increased silicon and aluminum (up to 1.6%) promote the formation of retained austenite, enhancing its transformation-induced plasticity effect. Both steels maintain carbon content around 0.1-0.2%, balancing strength and ductility for automotive applications.

Microstructure Differences

Dual Phase (DP) steel features a microstructure composed primarily of a soft ferrite matrix embedded with hard martensite islands, offering a balance of high strength and good ductility. TRIP (Transformation-Induced Plasticity) steel contains a multiphase microstructure consisting of ferrite, bainite, and retained austenite, which enhances ductility through strain-induced transformation of austenite to martensite during deformation. The key difference lies in the presence of retained austenite in TRIP steel, which significantly improves formability compared to the martensitic phase dominance in DP steel.

Mechanical Properties: Strength and Ductility

Dual Phase Steel exhibits a unique combination of high tensile strength, often ranging between 500-800 MPa, and excellent ductility due to its microstructure composed of martensite islands in a ferrite matrix. TRIP Steel achieves enhanced strength and ductility through the transformation-induced plasticity effect, with typical tensile strength values of 600-900 MPa and superior strain hardening capacity. The mechanical properties of Dual Phase Steel favor applications requiring rapid deformation resistance, while TRIP Steel is preferred for components needing significant energy absorption and formability.

Formability and Workability

Dual Phase Steel offers superior formability due to its microstructure of soft ferrite matrix with hard martensite islands, enabling enhanced elongation and dent resistance. TRIP Steel provides exceptional workability by utilizing the Transformation-Induced Plasticity effect, which increases strain hardening capacity and delays necking during forming processes. Both steels balance strength and ductility, but TRIP Steel excels in complex shaping applications due to its dynamic phase transformation.

Applications in the Automotive Industry

Dual Phase Steel is widely used in automotive manufacturing for components requiring a balance of high strength and formability, such as body panels and structural reinforcements. TRIP Steel enhances crashworthiness and energy absorption in safety-critical parts like bumpers and side impact beams due to its superior ductility and strain hardening properties. Both materials contribute to vehicle weight reduction and improved fuel efficiency by enabling thinner gauges without compromising mechanical performance.

Weldability and Joining Techniques

Dual Phase Steel exhibits improved weldability due to its simple microstructure, allowing stable weld pools and reducing the risk of cracking, which makes it suitable for conventional resistance spot welding and laser welding methods. TRIP Steel contains retained austenite that transforms under stress, enhancing strength and ductility but complicating welding processes by increasing susceptibility to hydrogen-induced cracking and requiring controlled heat input during fusion welding. Advanced joining techniques like friction stir welding and hybrid laser-arc welding have been explored to optimize weld quality in both steels while preserving mechanical properties.

Corrosion Resistance Performance

Dual phase steel typically exhibits lower corrosion resistance compared to TRIP steel due to its microstructure, which consists mainly of ferrite and martensite phases with less retained austenite. TRIP steel contains a significant amount of retained austenite that transforms to martensite under strain, enhancing its mechanical properties and providing a more uniform passive film that improves corrosion resistance. Studies show TRIP steels offer superior protection against rust and oxidative degradation in automotive and structural applications where exposure to harsh environments is common.

Cost Considerations and Market Availability

Dual Phase Steel generally offers lower production costs due to simpler heat treatment processes compared to TRIP Steel, which requires more complex alloying and processing to maintain its transformation-induced plasticity properties. Market availability favors Dual Phase Steel as it is widely used in automotive manufacturing for its balance of strength and ductility, while TRIP Steel, though offering superior mechanical properties, is less prevalent and consequently more expensive. Cost efficiency and supply chain maturity make Dual Phase Steel the preferred choice for high-volume applications, whereas TRIP Steel is reserved for specialized uses demanding enhanced formability and strength.

Future Trends in Advanced High-Strength Steels

Future trends in advanced high-strength steels emphasize increased use of Dual Phase (DP) steel and TRIP (Transformation-Induced Plasticity) steel due to their superior combination of strength and ductility. Innovations in alloy composition and heat treatment techniques aim to enhance microstructural stability, enabling better performance in automotive and aerospace applications. Integration of machine learning for optimized processing parameters is expected to accelerate development of next-generation AHSS with improved crashworthiness and weight reduction.

Dual Phase Steel vs TRIP Steel Infographic

materialdif.com

materialdif.com