Annealed steel offers enhanced ductility and reduced hardness, making it ideal for applications requiring easy machining and shaping. Tempered steel undergoes heat treatment to increase toughness and strength, providing better resistance to wear and fatigue. Choosing between annealed and tempered steel depends on the balance needed between flexibility and durability in specific industrial uses.

Table of Comparison

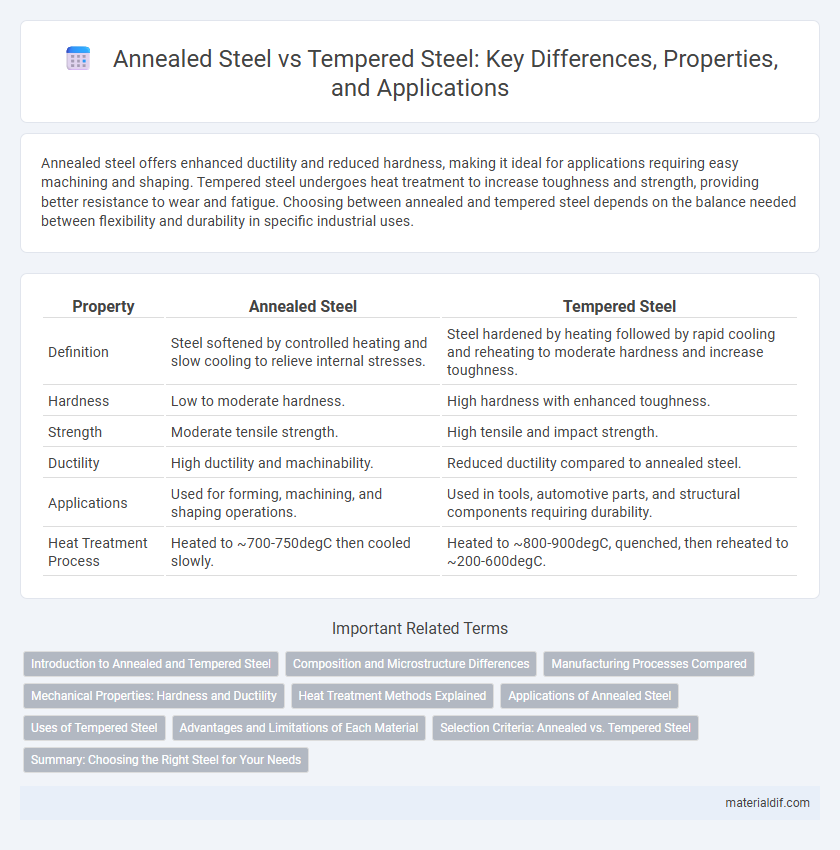

| Property | Annealed Steel | Tempered Steel |

|---|---|---|

| Definition | Steel softened by controlled heating and slow cooling to relieve internal stresses. | Steel hardened by heating followed by rapid cooling and reheating to moderate hardness and increase toughness. |

| Hardness | Low to moderate hardness. | High hardness with enhanced toughness. |

| Strength | Moderate tensile strength. | High tensile and impact strength. |

| Ductility | High ductility and machinability. | Reduced ductility compared to annealed steel. |

| Applications | Used for forming, machining, and shaping operations. | Used in tools, automotive parts, and structural components requiring durability. |

| Heat Treatment Process | Heated to ~700-750degC then cooled slowly. | Heated to ~800-900degC, quenched, then reheated to ~200-600degC. |

Introduction to Annealed and Tempered Steel

Annealed steel undergoes a heat treatment process that softens the metal, enhancing its ductility and reducing hardness for improved machinability and formability. Tempered steel is heated to a precise temperature below its critical point and then cooled, balancing hardness with toughness by relieving stresses from prior quenching. These heat treatments distinctly influence steel's microstructure, affecting its mechanical properties and suitability for specific industrial applications.

Composition and Microstructure Differences

Annealed steel features a ferrite-pearlite microstructure resulting from slow cooling, which reduces hardness and increases ductility by relieving internal stresses. Tempered steel undergoes controlled reheating after quenching, transforming martensite into tempered martensite, thereby balancing hardness and toughness. The compositional elements such as carbon content remain consistent, but the thermal treatment induces significant microstructural changes affecting mechanical properties.

Manufacturing Processes Compared

Annealed steel undergoes a slow cooling process after heating to reduce hardness and increase ductility, enhancing machinability and ease of fabrication. Tempered steel involves heating quenched steel to a lower temperature, balancing hardness and toughness by relieving internal stresses without compromising strength. The annealing process improves malleability, while tempering fine-tunes mechanical properties for durability in structural applications.

Mechanical Properties: Hardness and Ductility

Annealed steel exhibits lower hardness and higher ductility due to its softened microstructure, making it easier to machine and form. Tempered steel demonstrates increased hardness and improved toughness compared to annealed steel, resulting from heat treatment processes that refine its microstructure. The balance between hardness and ductility in tempered steel enhances its performance in applications requiring wear resistance and mechanical strength.

Heat Treatment Methods Explained

Annealed steel undergoes a heat treatment process where it is heated to a specific temperature and then slowly cooled to soften the metal, enhancing ductility and reducing hardness. Tempered steel is produced by heating quenched steel to a lower temperature and then cooling it, which increases toughness and reduces brittleness. These heat treatment methods fundamentally alter the microstructure of steel to optimize mechanical properties for various industrial applications.

Applications of Annealed Steel

Annealed steel is widely used in manufacturing applications requiring enhanced ductility and machinability, such as automotive components, structural parts, and metal forming processes. Its softened structure allows for easier shaping and cutting without cracking, making it ideal for sheet metal fabrication and wire production. The improved toughness and reduced hardness of annealed steel benefit applications in construction, pipelines, and equipment subject to cold working operations.

Uses of Tempered Steel

Tempered steel is widely used in applications requiring high strength and toughness, such as automotive components, cutting tools, and structural parts in construction. Its enhanced durability makes it ideal for manufacturing gears, springs, and blades that withstand heavy stress and impact. The material's resistance to wear and fatigue ensures long-lasting performance in industrial machinery and safety equipment.

Advantages and Limitations of Each Material

Annealed steel offers advantages such as improved ductility, reduced hardness, and enhanced machinability, making it ideal for processes requiring extensive shaping and forming, but it has lower strength and wear resistance compared to tempered steel. Tempered steel provides superior strength, toughness, and resistance to wear and fatigue due to controlled heat treatment, though it has less malleability and can be more prone to cracking under high stress if not properly tempered. Selecting between annealed and tempered steel depends on the application's need for either formability and softness or hardness and durability.

Selection Criteria: Annealed vs. Tempered Steel

Selection criteria for annealed versus tempered steel depend on the required mechanical properties and application environment; annealed steel offers enhanced ductility and machinability ideal for forming and welding processes, while tempered steel provides superior strength and hardness suitable for high-stress applications. Annealed steel is preferred when softer material with improved toughness is necessary, whereas tempered steel is selected to resist wear, fatigue, and deformation under heavy loads. The choice between annealed and tempered steel is driven by balancing flexibility requirements against strength and durability needs in industrial and structural components.

Summary: Choosing the Right Steel for Your Needs

Annealed steel offers enhanced ductility and reduced hardness, making it ideal for applications requiring extensive shaping or welding, while tempered steel provides increased strength and toughness suitable for structural components and tools exposed to high stress. Select annealed steel for processes demanding flexibility and formability, and opt for tempered steel when durability and resistance to wear are critical. Understanding the balance between softness and hardness ensures optimal performance tailored to specific industrial requirements.

Annealed steel vs Tempered steel Infographic

materialdif.com

materialdif.com