Drawn steel is produced by pulling metal through a die to achieve precise dimensions and a smooth surface finish, making it ideal for applications requiring uniformity and tight tolerances. Forged steel undergoes plastic deformation under high pressure, resulting in a denser grain structure with superior strength, toughness, and fatigue resistance. While drawn steel excels in dimensional accuracy, forged steel is preferred for critical components subjected to high stress and impact.

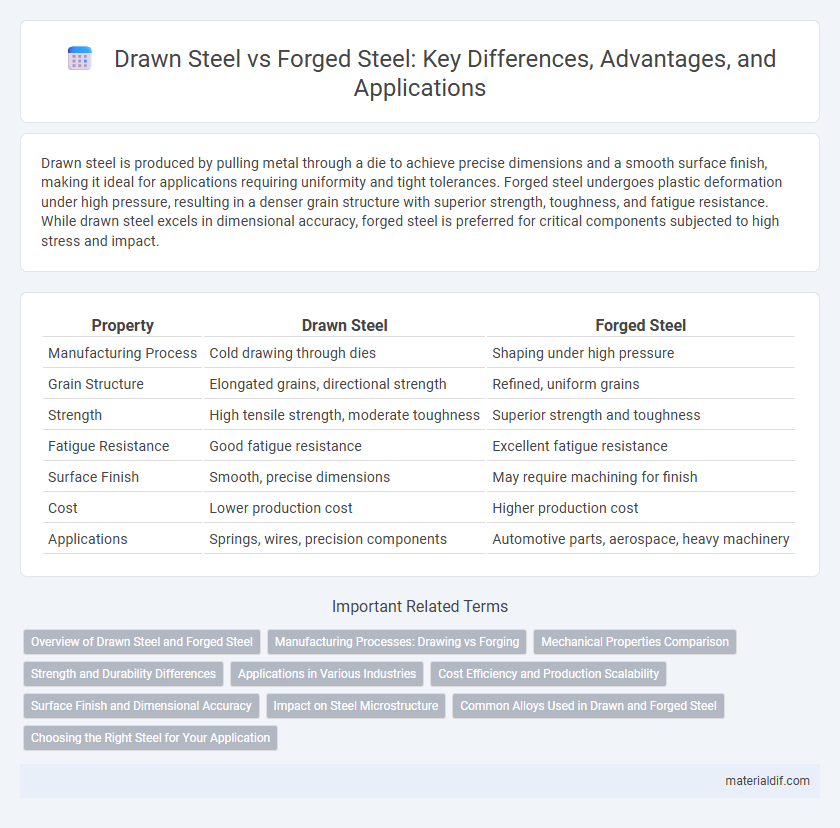

Table of Comparison

| Property | Drawn Steel | Forged Steel |

|---|---|---|

| Manufacturing Process | Cold drawing through dies | Shaping under high pressure |

| Grain Structure | Elongated grains, directional strength | Refined, uniform grains |

| Strength | High tensile strength, moderate toughness | Superior strength and toughness |

| Fatigue Resistance | Good fatigue resistance | Excellent fatigue resistance |

| Surface Finish | Smooth, precise dimensions | May require machining for finish |

| Cost | Lower production cost | Higher production cost |

| Applications | Springs, wires, precision components | Automotive parts, aerospace, heavy machinery |

Overview of Drawn Steel and Forged Steel

Drawn steel is produced by pulling a steel blank through a die to reduce its diameter, resulting in enhanced tensile strength and surface finish ideal for precision components. Forged steel undergoes plastic deformation through compressive forces, which aligns the grain structure to increase toughness, fatigue resistance, and impact strength, making it suitable for heavy-duty applications. Both processes improve mechanical properties but differ in microstructure control, dimensional accuracy, and typical use cases in industrial manufacturing.

Manufacturing Processes: Drawing vs Forging

Drawn steel involves pulling a heated steel billet through a die to reduce its diameter and increase its length, resulting in precise dimensional control and improved surface finish. Forged steel is shaped by compressive forces using hammers or presses to deform the heated metal, enhancing the material's internal grain structure for increased strength and toughness. Drawing emphasizes accuracy and surface quality, while forging prioritizes mechanical strength through grain alignment and density.

Mechanical Properties Comparison

Drawn steel exhibits higher tensile strength and improved surface finish due to cold working, enhancing its hardness and wear resistance compared to forged steel. Forged steel, however, offers superior toughness and impact resistance because of its refined grain structure from compressive forces during forging. This makes drawn steel ideal for applications requiring precision and strength, while forged steel suits high-stress components needing durability and fatigue resistance.

Strength and Durability Differences

Drawn steel exhibits high tensile strength due to its cold working process, resulting in enhanced hardness and resistance to wear. Forged steel offers superior durability with a refined grain structure that withstands impact and fatigue more effectively than drawn steel. The forging process produces components with greater toughness and structural integrity, making forged steel ideal for high-stress applications.

Applications in Various Industries

Drawn steel, known for its precise dimensional accuracy and smooth surface finish, is widely used in automotive components, machinery parts, and precision instruments where tight tolerances are crucial. Forged steel offers superior strength and toughness, making it ideal for heavy-duty applications such as aerospace, construction equipment, and oil and gas industry parts. Industries rely on drawn steel for lightweight, high-precision components while selecting forged steel for critical load-bearing and high-impact applications.

Cost Efficiency and Production Scalability

Drawn steel offers higher cost efficiency due to lower raw material waste and faster production cycles, making it ideal for large-scale manufacturing runs. Forged steel, while more expensive because of labor-intensive processes and equipment costs, provides superior mechanical properties for critical applications. Production scalability favors drawn steel through automation and minimal finishing requirements, whereas forging scales less efficiently due to complex tooling and longer processing times.

Surface Finish and Dimensional Accuracy

Drawn steel offers a smoother surface finish due to the cold drawing process, which reduces surface imperfections and enhances appearance, making it ideal for applications requiring high aesthetic standards. Forged steel typically exhibits superior dimensional accuracy and mechanical properties because the metal is shaped under high pressure, minimizing defects and internal voids. While drawn steel excels in surface quality, forged steel provides better structural integrity and precise tolerances for critical engineering components.

Impact on Steel Microstructure

Drawn steel undergoes plastic deformation through tensile forces, refining the grain structure and aligning the microstructure along the drawing direction, which enhances tensile strength and surface finish. Forged steel experiences compressive forces that induce grain flow conforming to the shape of the forging, resulting in a denser, more uniform microstructure with improved toughness and fatigue resistance. The distinct deformation methods in drawing and forging lead to significant variations in grain size, orientation, and retained stresses, critically impacting mechanical properties and performance.

Common Alloys Used in Drawn and Forged Steel

Common alloys used in drawn steel typically include low-carbon steels combined with elements like manganese, silicon, and chromium to enhance strength and ductility. Forged steel often incorporates medium to high-carbon alloys with added nickel, molybdenum, and vanadium to improve toughness, hardness, and resistance to wear. The specific alloy composition directly impacts the mechanical properties and suitability of drawn versus forged steel for various industrial applications.

Choosing the Right Steel for Your Application

Drawn steel offers superior surface finish and dimensional accuracy ideal for applications requiring precise, polished components such as automotive parts and tubing. Forged steel provides enhanced strength and toughness through grain refinement, making it suitable for high-stress applications like aerospace, heavy machinery, and structural components. Selecting between drawn and forged steel depends on factors like mechanical properties, desired strength, and application-specific performance requirements.

Drawn steel vs Forged steel Infographic

materialdif.com

materialdif.com