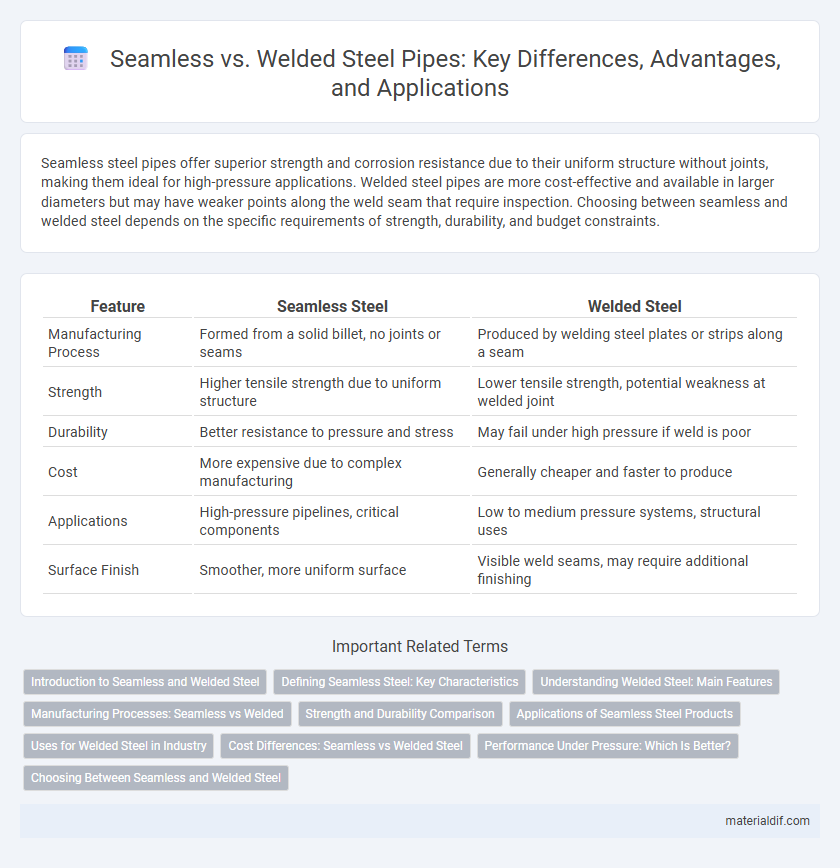

Seamless steel pipes offer superior strength and corrosion resistance due to their uniform structure without joints, making them ideal for high-pressure applications. Welded steel pipes are more cost-effective and available in larger diameters but may have weaker points along the weld seam that require inspection. Choosing between seamless and welded steel depends on the specific requirements of strength, durability, and budget constraints.

Table of Comparison

| Feature | Seamless Steel | Welded Steel |

|---|---|---|

| Manufacturing Process | Formed from a solid billet, no joints or seams | Produced by welding steel plates or strips along a seam |

| Strength | Higher tensile strength due to uniform structure | Lower tensile strength, potential weakness at welded joint |

| Durability | Better resistance to pressure and stress | May fail under high pressure if weld is poor |

| Cost | More expensive due to complex manufacturing | Generally cheaper and faster to produce |

| Applications | High-pressure pipelines, critical components | Low to medium pressure systems, structural uses |

| Surface Finish | Smoother, more uniform surface | Visible weld seams, may require additional finishing |

Introduction to Seamless and Welded Steel

Seamless steel pipes are manufactured by extruding a solid billet to create a hollow tube without any joints, offering superior strength and uniformity under high pressure and temperature conditions. Welded steel pipes are produced by rolling a flat steel plate and welding the edges together, providing cost-efficiency and versatility for applications where pressure requirements are moderate. The choice between seamless and welded steel depends on factors such as mechanical properties, pressure demands, and manufacturing costs used in industries like oil and gas, construction, and automotive.

Defining Seamless Steel: Key Characteristics

Seamless steel is characterized by its uniform, defect-free structure created through a specialized manufacturing process that eliminates weld seams, enhancing strength and resistance to high pressure. Its key characteristics include superior tensile strength, exceptional durability in extreme conditions, and consistent wall thickness, making it ideal for critical applications like pipelines, pressure vessels, and automotive components. The absence of welds reduces potential failure points, providing enhanced structural integrity compared to welded steel alternatives.

Understanding Welded Steel: Main Features

Welded steel is formed by joining metal pieces through heat or pressure, resulting in strong, uniform seams ideal for structural applications. Its main features include cost efficiency, faster production times, and the ability to create complex shapes with consistent mechanical properties. This type of steel is widely used in construction, pipelines, and automotive industries due to its versatility and reliability.

Manufacturing Processes: Seamless vs Welded

Seamless steel pipes are manufactured using a billet heated and pierced to create a hollow tube without any joints, resulting in a smoother surface and enhanced pressure resistance. Welded steel pipes are produced by bending and welding steel plates or coils along a longitudinal seam, allowing for custom sizes and easier mass production. The seamless process offers superior structural integrity for high-pressure applications, whereas welded pipes provide cost efficiency and flexibility in dimensions.

Strength and Durability Comparison

Seamless steel pipes exhibit superior strength due to their uniform structure, eliminating weak points caused by weld seams. Welded pipes may have weld joints that can be susceptible to corrosion and fatigue, reducing overall durability in high-pressure applications. Seamless steel's enhanced resistance to stress and pressure makes it ideal for critical applications demanding maximum reliability and long service life.

Applications of Seamless Steel Products

Seamless steel products are extensively used in high-pressure environments such as oil and gas pipelines, power plants, and chemical processing equipment due to their superior strength and resistance to corrosion. Their uniform structure without welded seams ensures enhanced durability and reliability, making them ideal for hydraulic cylinders, automotive parts, and aero-engine components. Industries demanding high performance and safety standards prefer seamless steel tubes for applications requiring critical pressure containment and structural integrity.

Uses for Welded Steel in Industry

Welded steel is extensively used in construction, automotive manufacturing, and pipeline infrastructure due to its cost-effectiveness and versatility in producing large, customized shapes. Its ability to withstand high pressure and stress makes it ideal for structural beams, pressure vessels, and industrial tanks. The ease of fabrication and repair further enhances its application in heavy machinery and transportation equipment.

Cost Differences: Seamless vs Welded Steel

Seamless steel pipes generally incur higher production costs due to their complex manufacturing process involving extrusion or rotary piercing, resulting in increased material and labor expenses. Welded steel pipes are more cost-effective as they are produced by rolling steel and welding the seam, which simplifies manufacturing and reduces raw material waste. While seamless pipes offer superior strength and resistance to pressure, welded pipes provide a budget-friendly option suitable for less demanding applications.

Performance Under Pressure: Which Is Better?

Seamless steel pipes provide superior performance under high pressure due to their uniform structure and lack of welded joints, reducing the risk of weak points or leaks. Welded steel pipes, while more cost-effective and available in larger diameters, are generally less reliable under extreme pressure because the welded seams can be potential points of failure. In industries such as oil and gas or high-pressure steam systems, seamless pipes are preferred for their enhanced strength and durability.

Choosing Between Seamless and Welded Steel

Choosing between seamless and welded steel depends primarily on the application's pressure and structural requirements. Seamless steel offers superior strength and corrosion resistance due to its uniform structure, making it ideal for high-pressure environments like oil and gas pipelines. Welded steel is more cost-effective and suitable for lower-pressure applications such as construction beams and water pipelines, where customization and size flexibility are important.

Seamless vs Welded Infographic

materialdif.com

materialdif.com