Full annealed steel undergoes a controlled heating and slow cooling process, resulting in a softer, more ductile material with improved machinability and reduced internal stresses. Quenched steel is rapidly cooled from a high temperature, producing a hard, brittle microstructure known as martensite, which significantly increases strength and wear resistance. Choosing between full annealed and quenched steel depends on the application's requirement for toughness versus hardness and machinability.

Table of Comparison

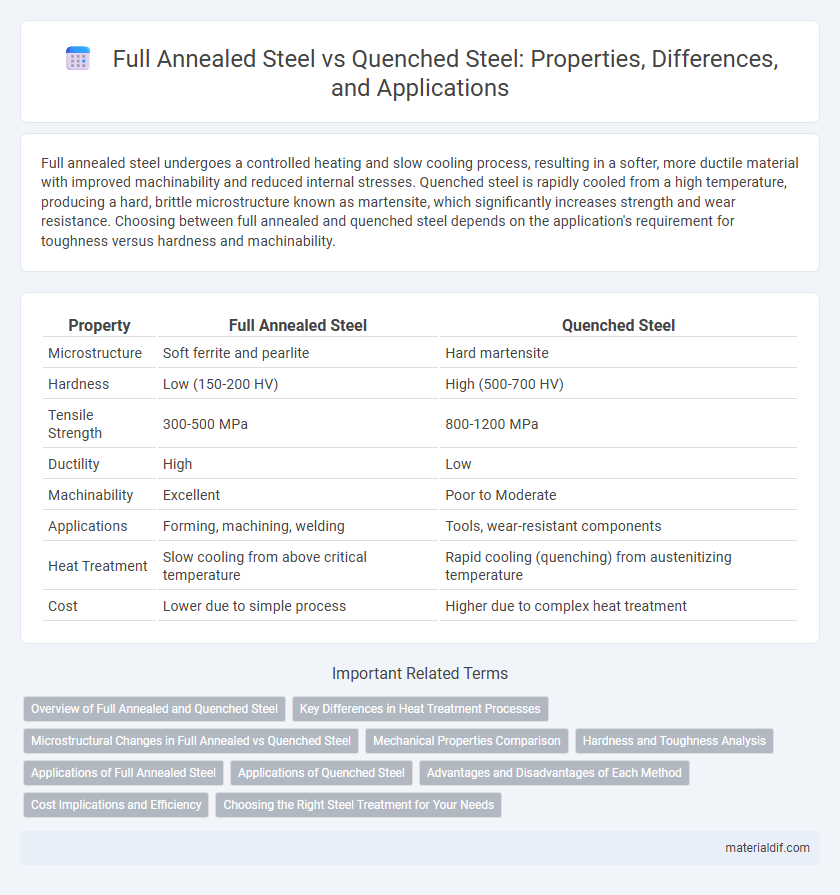

| Property | Full Annealed Steel | Quenched Steel |

|---|---|---|

| Microstructure | Soft ferrite and pearlite | Hard martensite |

| Hardness | Low (150-200 HV) | High (500-700 HV) |

| Tensile Strength | 300-500 MPa | 800-1200 MPa |

| Ductility | High | Low |

| Machinability | Excellent | Poor to Moderate |

| Applications | Forming, machining, welding | Tools, wear-resistant components |

| Heat Treatment | Slow cooling from above critical temperature | Rapid cooling (quenching) from austenitizing temperature |

| Cost | Lower due to simple process | Higher due to complex heat treatment |

Overview of Full Annealed and Quenched Steel

Full annealed steel undergoes a heating process followed by slow cooling, resulting in enhanced ductility, reduced hardness, and improved machinability, making it ideal for forming and shaping operations. Quenched steel is rapidly cooled from a high temperature, increasing hardness and strength through the formation of martensitic microstructures, which enhances wear resistance but reduces ductility. The choice between full annealed and quenched steel depends on the required balance of mechanical properties for specific industrial applications such as automotive components or structural materials.

Key Differences in Heat Treatment Processes

Full annealed steel undergoes a heat treatment process where the steel is heated to a temperature above its critical range and slowly cooled to soften the material and improve ductility. Quenched steel is rapidly cooled from a high temperature, typically by immersion in water or oil, resulting in increased hardness and strength but reduced ductility. These key differences in heat treatment significantly affect the mechanical properties and applications of each steel type.

Microstructural Changes in Full Annealed vs Quenched Steel

Full annealed steel exhibits a coarse pearlite or spheroidized microstructure characterized by uniformly distributed cementite particles within a ferrite matrix, resulting from slow cooling that reduces internal stresses and enhances ductility. Quenched steel, on the other hand, forms a martensitic microstructure with needle-like, highly strained lattices due to rapid cooling, significantly increasing hardness and tensile strength but decreasing toughness. These distinct microstructural transformations directly influence mechanical properties, with annealing promoting machinability and quenching optimizing strength for high-performance applications.

Mechanical Properties Comparison

Full annealed steel exhibits lower hardness and tensile strength but significantly higher ductility and toughness compared to quenched steel, making it more suitable for applications requiring extensive deformation without failure. Quenched steel, characterized by rapid cooling, has enhanced hardness and tensile strength due to the formation of martensitic microstructure, but it is generally more brittle and prone to cracking under impact. The choice between full annealed and quenched steel depends on the mechanical property requirements such as impact resistance, machinability, and load-bearing capacity in engineering applications.

Hardness and Toughness Analysis

Full annealed steel exhibits lower hardness but superior toughness due to its softer, more ductile microstructure achieved through slow cooling. Quenched steel, rapidly cooled from a high temperature, gains significantly increased hardness at the expense of reduced toughness, making it more brittle. This hardness-toughness trade-off is critical in selecting steel grades for applications requiring specific mechanical performance.

Applications of Full Annealed Steel

Full annealed steel is widely used in applications requiring improved machinability, enhanced ductility, and uniform microstructure, such as automotive components, structural parts, and heavy machinery. Its softer and more workable properties make it ideal for processes like forging, stamping, and machining before final heat treatment. Full annealing is preferred in manufacturing where stress relief and dimensional stability are critical, including in aerospace and construction industries.

Applications of Quenched Steel

Quenched steel is widely used in applications requiring high strength and wear resistance, such as automotive components, cutting tools, and heavy machinery parts. Its hardened microstructure improves fatigue resistance, making it ideal for springs, gears, and shafts subjected to cyclic loads. The enhanced toughness and durability of quenched steel ensure reliable performance in demanding industrial environments.

Advantages and Disadvantages of Each Method

Full annealed steel offers improved ductility and machinability due to its softened microstructure, making it ideal for complex forming processes, but it has lower tensile strength and wear resistance compared to quenched steel. Quenched steel exhibits superior hardness, tensile strength, and wear resistance from rapid cooling, enhancing performance in demanding applications, though it tends to be more brittle and may require subsequent tempering to reduce stress and improve toughness. The choice between full annealed and quenched steel depends on application requirements for flexibility, strength, and durability.

Cost Implications and Efficiency

Full annealed steel generally incurs higher upfront costs due to its extended heat treatment process, resulting in improved ductility and machinability compared to quenched steel. Quenched steel, while more cost-effective initially, offers superior strength and hardness but may require additional processing or maintenance to prevent brittleness and failure. Efficiency considerations should weigh the total lifecycle costs, including potential savings in machining, repair, and performance durability associated with each treatment method.

Choosing the Right Steel Treatment for Your Needs

Full annealed steel offers enhanced ductility and machinability by relieving internal stresses through slow cooling, making it ideal for applications requiring extensive forming or welding. Quenched steel, subjected to rapid cooling, provides superior hardness and strength, suitable for wear-resistant tools and structural components under high stress. Selecting the appropriate steel treatment depends on balancing mechanical properties with intended use, where annealing prioritizes flexibility and quenching emphasizes durability.

Full Annealed Steel vs Quenched Steel Infographic

materialdif.com

materialdif.com