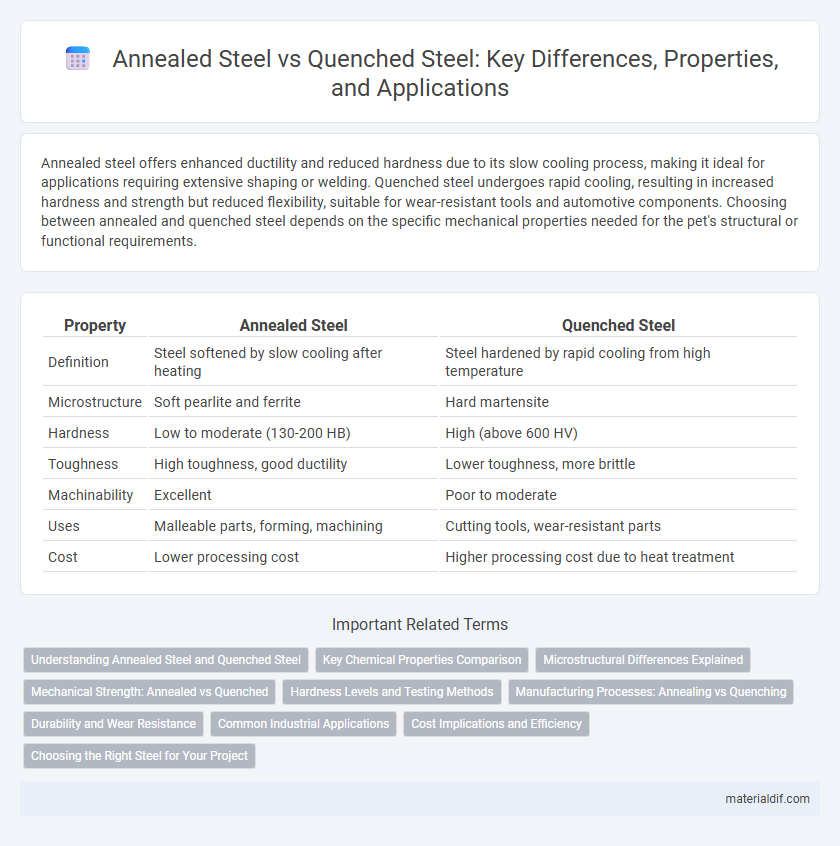

Annealed steel offers enhanced ductility and reduced hardness due to its slow cooling process, making it ideal for applications requiring extensive shaping or welding. Quenched steel undergoes rapid cooling, resulting in increased hardness and strength but reduced flexibility, suitable for wear-resistant tools and automotive components. Choosing between annealed and quenched steel depends on the specific mechanical properties needed for the pet's structural or functional requirements.

Table of Comparison

| Property | Annealed Steel | Quenched Steel |

|---|---|---|

| Definition | Steel softened by slow cooling after heating | Steel hardened by rapid cooling from high temperature |

| Microstructure | Soft pearlite and ferrite | Hard martensite |

| Hardness | Low to moderate (130-200 HB) | High (above 600 HV) |

| Toughness | High toughness, good ductility | Lower toughness, more brittle |

| Machinability | Excellent | Poor to moderate |

| Uses | Malleable parts, forming, machining | Cutting tools, wear-resistant parts |

| Cost | Lower processing cost | Higher processing cost due to heat treatment |

Understanding Annealed Steel and Quenched Steel

Annealed steel undergoes a controlled heating and slow cooling process to soften the metal, enhancing ductility and reducing hardness for improved machinability. Quenched steel is rapidly cooled from a high temperature, increasing hardness and strength while sacrificing some ductility. Understanding the thermal treatment effects on steel microstructure is essential for selecting the appropriate steel for specific mechanical applications.

Key Chemical Properties Comparison

Annealed steel exhibits a lower carbon content and reduced hardness due to its slow cooling process, resulting in a more ductile microstructure dominated by ferrite and pearlite phases. Quenched steel contains higher carbon concentration and increased hardness, characterized by a martensitic microstructure formed through rapid cooling, enhancing tensile strength and wear resistance. Key chemical distinctions lie in carbon percentage and phase composition, directly influencing mechanical properties and applications.

Microstructural Differences Explained

Annealed steel features a refined microstructure with uniform, equiaxed grains and reduced dislocation density, resulting in improved ductility and reduced hardness. Quenched steel exhibits a martensitic microstructure characterized by needle-like, supersaturated carbon phases that significantly increase hardness and strength but reduce ductility. The key microstructural difference lies in annealing promoting grain growth and stress relief, while quenching traps carbon atoms in a distorted lattice, producing a hard and brittle structure.

Mechanical Strength: Annealed vs Quenched

Annealed steel exhibits lower mechanical strength due to its softened microstructure, making it more malleable and easier to machine. Quenched steel undergoes rapid cooling that produces a martensitic structure, significantly increasing its hardness and tensile strength. The enhanced mechanical strength of quenched steel makes it ideal for applications requiring wear resistance and durability.

Hardness Levels and Testing Methods

Annealed steel exhibits lower hardness levels due to its heat treatment process that softens the metal, enhancing ductility and machinability. Quenched steel undergoes rapid cooling, significantly increasing hardness and strength by creating a martensitic microstructure. Hardness levels are typically measured using Rockwell, Brinell, or Vickers hardness tests, with quenched steel showing higher numerical values compared to annealed steel in these standardized assessments.

Manufacturing Processes: Annealing vs Quenching

Annealed steel undergoes a controlled heating process followed by slow cooling, which reduces hardness and increases ductility, making it easier to machine and shape. Quenched steel is rapidly cooled from a high temperature, typically in water or oil, resulting in a harder, more brittle microstructure due to the formation of martensite. These distinct manufacturing processes directly influence the mechanical properties and applications of the steel in industries requiring specific strength and flexibility characteristics.

Durability and Wear Resistance

Annealed steel exhibits enhanced ductility and reduced hardness, making it less resistant to wear but more durable against impact and deformation. Quenched steel undergoes rapid cooling, resulting in a harder microstructure that significantly improves wear resistance and overall durability under abrasive conditions. The choice between annealed and quenched steel depends on specific application requirements balancing toughness and surface hardness.

Common Industrial Applications

Annealed steel, known for its increased ductility and reduced hardness, is commonly utilized in applications such as automotive body panels, structural components, and metal forming processes where flexibility and ease of machining are critical. Quenched steel, characterized by its high hardness and strength due to rapid cooling, finds widespread use in tools, automotive parts like gears and shafts, heavy machinery components, and wear-resistant equipment requiring durability under high stress. The choice between annealed and quenched steel directly impacts manufacturing processes and performance outcomes across industries such as construction, automotive, and machinery production.

Cost Implications and Efficiency

Annealed steel generally costs less due to a simpler heat treatment process that involves slow cooling, reducing energy consumption and machining costs. Quenched steel, though more expensive because of rapid cooling methods and required tempering, offers higher strength and hardness, leading to enhanced efficiency in applications needing durability and wear resistance. Evaluating project requirements against these cost and performance trade-offs helps optimize material selection for budget and operational efficiency.

Choosing the Right Steel for Your Project

Annealed steel offers enhanced ductility and machinability, making it ideal for projects requiring extensive shaping or welding, while quenched steel provides superior hardness and strength suited for applications demanding wear resistance and durability. Understanding the specific mechanical properties needed, such as tensile strength and impact tolerance, is crucial for selecting annealed or quenched steel tailored to structural or manufacturing requirements. Project conditions like load stress, environmental exposure, and fabrication processes determine the optimal heat treatment choice to ensure performance and longevity.

Annealed Steel vs Quenched Steel Infographic

materialdif.com

materialdif.com