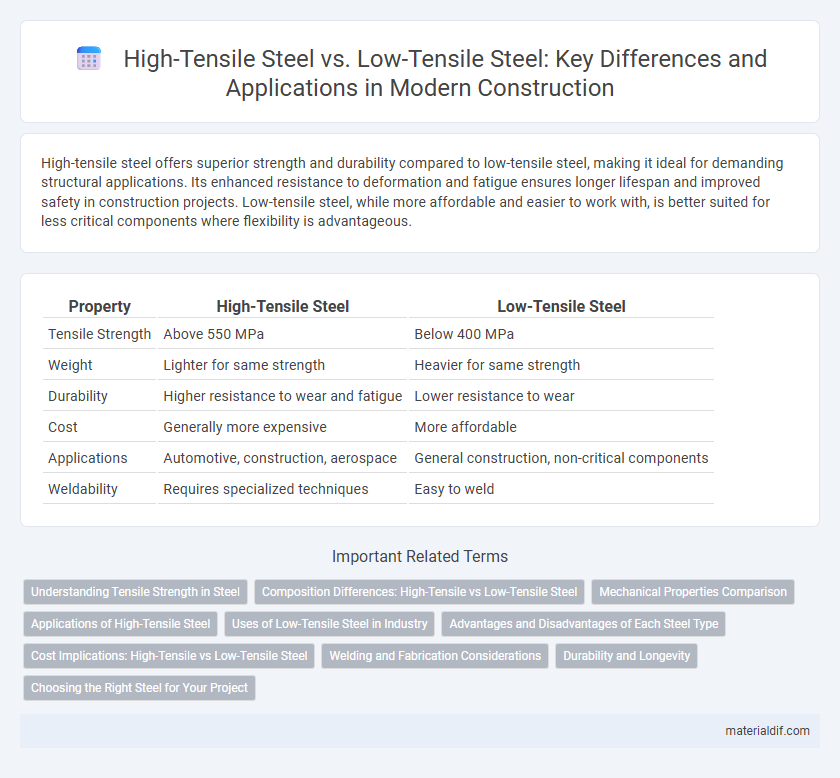

High-tensile steel offers superior strength and durability compared to low-tensile steel, making it ideal for demanding structural applications. Its enhanced resistance to deformation and fatigue ensures longer lifespan and improved safety in construction projects. Low-tensile steel, while more affordable and easier to work with, is better suited for less critical components where flexibility is advantageous.

Table of Comparison

| Property | High-Tensile Steel | Low-Tensile Steel |

|---|---|---|

| Tensile Strength | Above 550 MPa | Below 400 MPa |

| Weight | Lighter for same strength | Heavier for same strength |

| Durability | Higher resistance to wear and fatigue | Lower resistance to wear |

| Cost | Generally more expensive | More affordable |

| Applications | Automotive, construction, aerospace | General construction, non-critical components |

| Weldability | Requires specialized techniques | Easy to weld |

Understanding Tensile Strength in Steel

High-tensile steel exhibits a tensile strength typically above 500 megapascals (MPa), enabling superior resistance to stress and deformation compared to low-tensile steel, which usually ranges between 250 to 400 MPa. The enhanced carbon and alloy content in high-tensile steel contributes to increased durability, making it ideal for structural applications and heavy-duty manufacturing. Understanding tensile strength is crucial for selecting the appropriate steel type to ensure safety, performance, and longevity in engineering projects.

Composition Differences: High-Tensile vs Low-Tensile Steel

High-tensile steel contains higher amounts of carbon, manganese, and other alloying elements such as chromium and nickel, enhancing its strength and durability compared to low-tensile steel. Low-tensile steel features lower carbon content and fewer alloying elements, resulting in greater ductility but reduced tensile strength. The varying composition influences mechanical properties, making high-tensile steel suitable for structural applications requiring enhanced load-bearing capacity.

Mechanical Properties Comparison

High-tensile steel exhibits superior mechanical properties, including higher yield strength ranging from 450 to 700 MPa compared to low-tensile steel's 250 to 400 MPa. Its enhanced tensile strength results in improved resistance to deformation and higher load-bearing capacity, making it ideal for structural applications requiring durability. Low-tensile steel, with lower ductility and tensile strength, is generally easier to weld and form but is less suitable for high-stress environments.

Applications of High-Tensile Steel

High-tensile steel's superior strength-to-weight ratio makes it ideal for critical applications in automotive manufacturing, reducing vehicle weight while enhancing safety and fuel efficiency. In construction, it is extensively used for high-rise buildings and bridges, where load-bearing capacity and durability are paramount. Its resistance to deformation and fatigue also benefits heavy machinery and aerospace components, ensuring long service life under extreme stress conditions.

Uses of Low-Tensile Steel in Industry

Low-tensile steel is widely used in construction for non-structural components, such as cladding, roofing, and piping, due to its flexibility and ease of fabrication. It is preferred in manufacturing applications where high strength is less critical, including automotive body panels and household appliances. The steel's cost-effectiveness and good weldability make it ideal for producing components requiring moderate durability without the need for high tensile strength.

Advantages and Disadvantages of Each Steel Type

High-tensile steel offers superior strength and durability, making it ideal for construction projects requiring load-bearing capacity and resistance to impact, but it can be more expensive and less ductile compared to low-tensile steel. Low-tensile steel provides greater flexibility and ease of fabrication, which reduces manufacturing costs and improves weldability, though it sacrifices strength and is more prone to deformation under heavy stress. Choosing between high-tensile and low-tensile steel depends on balancing the need for structural performance against cost-efficiency and formability in specific applications.

Cost Implications: High-Tensile vs Low-Tensile Steel

High-tensile steel offers superior strength, reducing material usage and overall structural weight, which can lead to cost savings in transportation and labor. Low-tensile steel typically has a lower upfront cost but may require thicker sections or more reinforcement, increasing long-term expenses. Evaluating project requirements and load conditions is essential for optimizing cost-effectiveness between high-tensile and low-tensile steel selections.

Welding and Fabrication Considerations

High-tensile steel requires precise welding techniques such as preheating and controlled cooling to prevent cracking and maintain structural integrity, whereas low-tensile steel allows for more straightforward welding with standard procedures. Fabrication of high-tensile steel demands specialized equipment and skilled labor to handle its strength and hardness, making it more expensive and time-consuming compared to low-tensile steel. Selecting appropriate welding consumables and following recommended heat input parameters are critical factors in achieving durable welds in high-tensile steel applications.

Durability and Longevity

High-tensile steel exhibits superior durability compared to low-tensile steel due to its enhanced strength and resistance to deformation under stress. This increased tensile strength contributes to greater longevity in structural applications, reducing the need for frequent repairs or replacements. Low-tensile steel, while easier to work with, typically wears out faster and is more susceptible to fatigue and corrosion in demanding environments.

Choosing the Right Steel for Your Project

High-tensile steel offers superior strength and durability, making it ideal for structural applications requiring high load-bearing capacity and resistance to deformation. Low-tensile steel, being more ductile and easier to weld, suits projects where flexibility and cost-effectiveness are prioritized over maximum strength. Selecting the right steel depends on project-specific factors such as load requirements, environmental conditions, and budget constraints to ensure optimal performance and longevity.

High-Tensile Steel vs Low-Tensile Steel Infographic

materialdif.com

materialdif.com