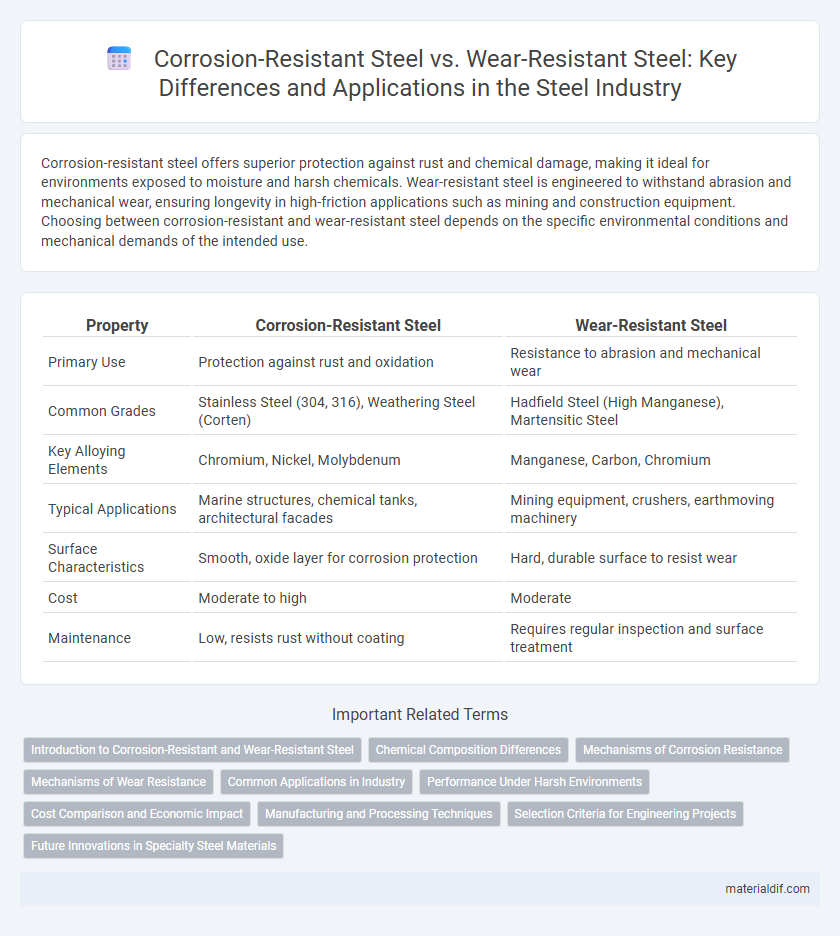

Corrosion-resistant steel offers superior protection against rust and chemical damage, making it ideal for environments exposed to moisture and harsh chemicals. Wear-resistant steel is engineered to withstand abrasion and mechanical wear, ensuring longevity in high-friction applications such as mining and construction equipment. Choosing between corrosion-resistant and wear-resistant steel depends on the specific environmental conditions and mechanical demands of the intended use.

Table of Comparison

| Property | Corrosion-Resistant Steel | Wear-Resistant Steel |

|---|---|---|

| Primary Use | Protection against rust and oxidation | Resistance to abrasion and mechanical wear |

| Common Grades | Stainless Steel (304, 316), Weathering Steel (Corten) | Hadfield Steel (High Manganese), Martensitic Steel |

| Key Alloying Elements | Chromium, Nickel, Molybdenum | Manganese, Carbon, Chromium |

| Typical Applications | Marine structures, chemical tanks, architectural facades | Mining equipment, crushers, earthmoving machinery |

| Surface Characteristics | Smooth, oxide layer for corrosion protection | Hard, durable surface to resist wear |

| Cost | Moderate to high | Moderate |

| Maintenance | Low, resists rust without coating | Requires regular inspection and surface treatment |

Introduction to Corrosion-Resistant and Wear-Resistant Steel

Corrosion-resistant steel is engineered to withstand chemical or environmental damage by forming a protective oxide layer, commonly found in stainless steel varieties with chromium content above 10.5%. Wear-resistant steel, such as AR400 or AR500 grades, is designed to endure mechanical abrasion and impact, featuring high hardness and toughness through alloying elements like manganese and carbon. Understanding the distinct properties of these steels ensures optimal material selection for applications requiring either prolonged exposure to corrosive environments or high-impact wear resistance.

Chemical Composition Differences

Corrosion-resistant steel typically contains higher levels of chromium, often above 10.5%, along with elements like nickel and molybdenum, which enhance its resistance to oxidation and chemical attack. Wear-resistant steel is enriched with carbon and alloying elements such as manganese, silicon, and sometimes boron, designed to improve hardness and abrasion resistance. These distinct chemical compositions tailor each steel type for specific performance needs, with corrosion-resistant steel focusing on durability in harsh environments and wear-resistant steel prioritizing mechanical strength and surface endurance.

Mechanisms of Corrosion Resistance

Corrosion-resistant steel relies on the formation of a passive oxide layer, primarily chromium oxide, which acts as a protective barrier against environmental factors such as moisture and oxygen. This passive film continuously repairs itself when damaged, preventing further oxidation and degradation of the steel surface. In contrast to wear-resistant steel, which focuses on hardness and abrasion resistance, corrosion-resistant steel emphasizes chemical composition and microstructure to inhibit electrochemical reactions that lead to rust and corrosion.

Mechanisms of Wear Resistance

Wear-resistant steel primarily relies on hardness and microstructural features like carbides to resist abrasion, adhesion, and impact, preventing material loss under mechanical stress. Corrosion-resistant steel achieves durability by forming a passive oxide layer, protecting against chemical degradation rather than mechanical wear. The mechanisms differ fundamentally: wear resistance focuses on physical barrier properties against mechanical forces, while corrosion resistance depends on chemical stability in aggressive environments.

Common Applications in Industry

Corrosion-resistant steel is widely used in chemical processing, marine environments, and infrastructure exposed to moisture and harsh chemicals, where preventing rust and degradation is critical. Wear-resistant steel finds common applications in mining equipment, construction machinery, and heavy-duty industrial tools, where surface durability and impact resistance are essential. Both types of steel optimize performance and lifespan in demanding industrial conditions by addressing specific environmental and mechanical challenges.

Performance Under Harsh Environments

Corrosion-resistant steel excels in environments with high moisture, chemicals, and salt exposure, maintaining integrity by resisting rust and oxidation. Wear-resistant steel performs best under abrasive conditions, offering superior hardness and toughness to withstand friction and impact. Both steels are engineered for harsh environments but target different degradation mechanisms, optimizing durability based on specific operational stresses.

Cost Comparison and Economic Impact

Corrosion-resistant steel generally incurs higher upfront costs due to alloying elements like chromium and nickel but offers long-term savings by reducing maintenance and replacement expenses in harsh environments. Wear-resistant steel typically costs less initially but may require more frequent repairs or replacements when used in abrasive conditions, impacting overall operational expenses. Evaluating the total lifecycle cost reveals that corrosion-resistant steel can provide better economic value in applications exposed to corrosive agents, while wear-resistant steel suits high-impact scenarios with lower corrosion risk.

Manufacturing and Processing Techniques

Corrosion-resistant steel is manufactured using alloying elements like chromium, nickel, and molybdenum, which enhance its ability to form a passive oxide layer that protects against oxidation and chemical degradation. Wear-resistant steel undergoes specialized heat treatments such as quenching and tempering to increase hardness and toughness, often combined with surface hardening techniques like carburizing or nitriding to improve abrasion resistance. Both types require precise control of manufacturing parameters, including soaking time and cooling rates, to optimize microstructure and performance for specific industrial applications.

Selection Criteria for Engineering Projects

Corrosion-resistant steel is essential in engineering projects exposed to harsh chemical environments or moisture, designed to withstand oxidation and extend structural lifespan. Wear-resistant steel is prioritized when abrasion, impact, or mechanical wear dominate, requiring materials with high hardness and toughness to maintain integrity under heavy use. Selection criteria hinge on environmental conditions, mechanical demands, and expected service life, ensuring optimal performance and cost-efficiency in industrial applications.

Future Innovations in Specialty Steel Materials

Future innovations in specialty steel materials emphasize enhanced corrosion-resistant alloys incorporating nanostructured coatings and self-healing properties to significantly extend service life in harsh environments. Advanced wear-resistant steel developments leverage novel composite microstructures and additive manufacturing techniques to achieve superior hardness and impact resistance for industrial applications. Integration of smart sensing technologies within these steels enables real-time monitoring and predictive maintenance, revolutionizing durability and performance in next-generation infrastructure and machinery.

Corrosion-resistant steel vs Wear-resistant steel Infographic

materialdif.com

materialdif.com