Forged steel is produced by shaping heated steel using compressive forces, resulting in a denser and stronger grain structure compared to cast steel, which is created by pouring molten metal into molds. This difference in manufacturing leads forged steel to exhibit superior mechanical properties, such as higher tensile strength and better fatigue resistance. Cast steel, while offering excellent design flexibility and cost-effectiveness for complex shapes, generally has lower strength and toughness than forged steel.

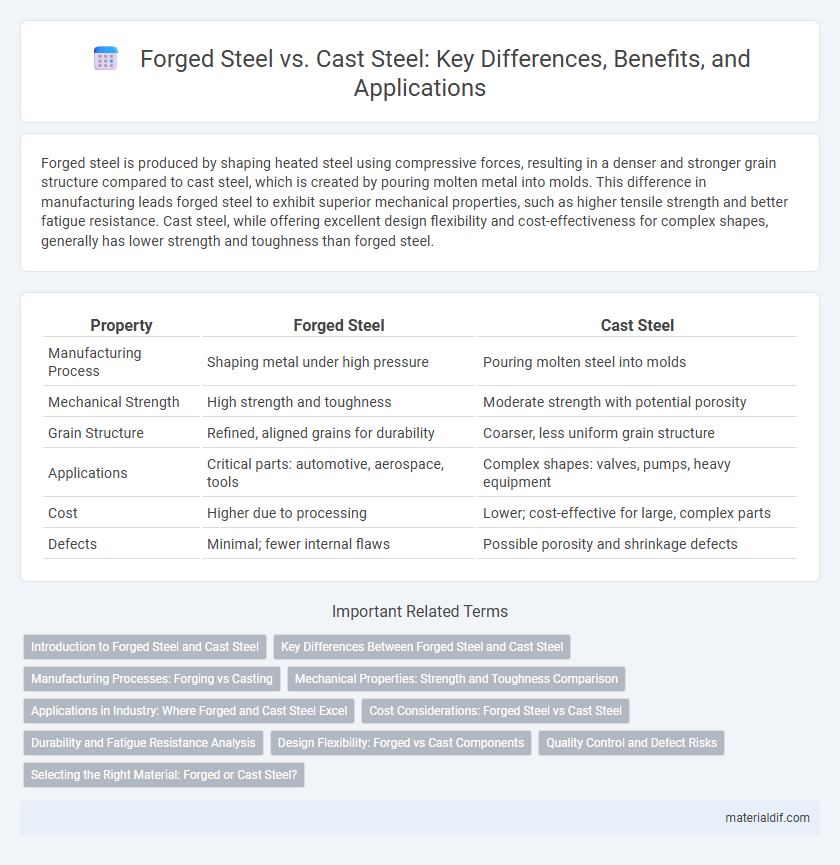

Table of Comparison

| Property | Forged Steel | Cast Steel |

|---|---|---|

| Manufacturing Process | Shaping metal under high pressure | Pouring molten steel into molds |

| Mechanical Strength | High strength and toughness | Moderate strength with potential porosity |

| Grain Structure | Refined, aligned grains for durability | Coarser, less uniform grain structure |

| Applications | Critical parts: automotive, aerospace, tools | Complex shapes: valves, pumps, heavy equipment |

| Cost | Higher due to processing | Lower; cost-effective for large, complex parts |

| Defects | Minimal; fewer internal flaws | Possible porosity and shrinkage defects |

Introduction to Forged Steel and Cast Steel

Forged steel is produced by shaping metal under high pressure, resulting in a dense structure with enhanced strength and toughness. Cast steel is made by melting and pouring molten steel into molds, allowing for complex shapes but with a coarser grain structure compared to forging. Forging improves mechanical properties such as fatigue resistance and impact strength, while casting offers design flexibility and cost-effective production for large, intricate components.

Key Differences Between Forged Steel and Cast Steel

Forged steel exhibits a denser grain structure and superior mechanical properties compared to cast steel, resulting from the metal being shaped under high pressure, which enhances strength and fatigue resistance. Cast steel, produced by pouring molten metal into molds, typically has a more uniform shape but contains coarser grain and potential internal cavities, making it less tough and more brittle. Key differences include forged steel's higher tensile strength, improved ductility, and better impact resistance versus cast steel's cost-effective manufacturing and complex geometrical capabilities.

Manufacturing Processes: Forging vs Casting

Forged steel is produced by shaping heated metal under high pressure, resulting in a dense, fine-grained microstructure that enhances strength and toughness. Cast steel is formed by pouring molten metal into molds, allowing complex shapes but often leading to coarser grain structures and potential internal porosity. The forging process typically yields superior mechanical properties and fatigue resistance, while casting offers greater design flexibility and cost-effectiveness for complex geometries.

Mechanical Properties: Strength and Toughness Comparison

Forged steel exhibits superior mechanical properties with higher strength and toughness compared to cast steel due to its refined grain structure formed under compressive forces. The forging process aligns the internal grain flow, enhancing resistance to impact and fatigue, making forged steel ideal for high-stress applications. Cast steel, while easier to shape into complex geometries, typically has lower tensile strength and fracture toughness because of inherent porosity and potential internal defects.

Applications in Industry: Where Forged and Cast Steel Excel

Forged steel excels in applications requiring high strength, toughness, and resistance to fatigue, making it ideal for aerospace components, automotive parts, and heavy machinery. Cast steel is preferred for complex shapes and large parts such as valves, pumps, and heavy equipment housings due to its excellent castability and cost efficiency. Both materials are critical in industries where mechanical properties and design flexibility determine performance and durability.

Cost Considerations: Forged Steel vs Cast Steel

Forged steel generally incurs higher initial costs due to the intensive labor and energy required for shaping through compressive forces, while cast steel involves lower tooling expenses but may have increased post-processing costs to correct defects. The durability and structural integrity of forged steel often justify its premium price in applications demanding high strength and fatigue resistance. Cast steel offers cost-effective production for complex shapes and large volumes despite potential compromises in mechanical properties and the necessity for quality inspections.

Durability and Fatigue Resistance Analysis

Forged steel exhibits superior durability and fatigue resistance compared to cast steel due to its refined grain structure and reduced porosity achieved through plastic deformation processes. The directional grain flow in forged steel enhances mechanical properties, making it less susceptible to crack initiation and propagation under cyclic loading. Cast steel, while cost-effective for complex shapes, typically contains internal defects and coarse microstructures that reduce its fatigue performance and overall toughness.

Design Flexibility: Forged vs Cast Components

Forged steel offers superior design flexibility by allowing more intricate and precise shaping through controlled deformation, resulting in components with enhanced strength and fatigue resistance. Cast steel enables the creation of complex geometries and hollow sections that are difficult to achieve with forging, making it ideal for intricate shapes and large parts. Both processes cater to different design requirements, with forging excelling in strength-critical applications and casting providing versatility in complex structural designs.

Quality Control and Defect Risks

Forged steel undergoes rigorous quality control through controlled deformation processes, resulting in a dense, uniform grain structure that significantly reduces defect risks such as porosity and inclusions. In contrast, cast steel is more susceptible to defects like shrinkage cavities and segregation due to solidification patterns, requiring extensive non-destructive testing to ensure integrity. The superior mechanical properties and lower incidence of internal flaws make forged steel preferable in high-stress, critical applications.

Selecting the Right Material: Forged or Cast Steel?

Selecting the right material between forged and cast steel depends on the application's strength and durability requirements, with forged steel offering superior grain structure and mechanical properties ideal for high-stress conditions. Cast steel provides complex shapes and cost efficiency for less demanding applications but has a coarser grain structure, making it less suitable for impact or fatigue resistance. Evaluating factors such as load-bearing needs, toughness, and manufacturing complexity ensures optimal performance and longevity in steel components.

Forged steel vs Cast steel Infographic

materialdif.com

materialdif.com