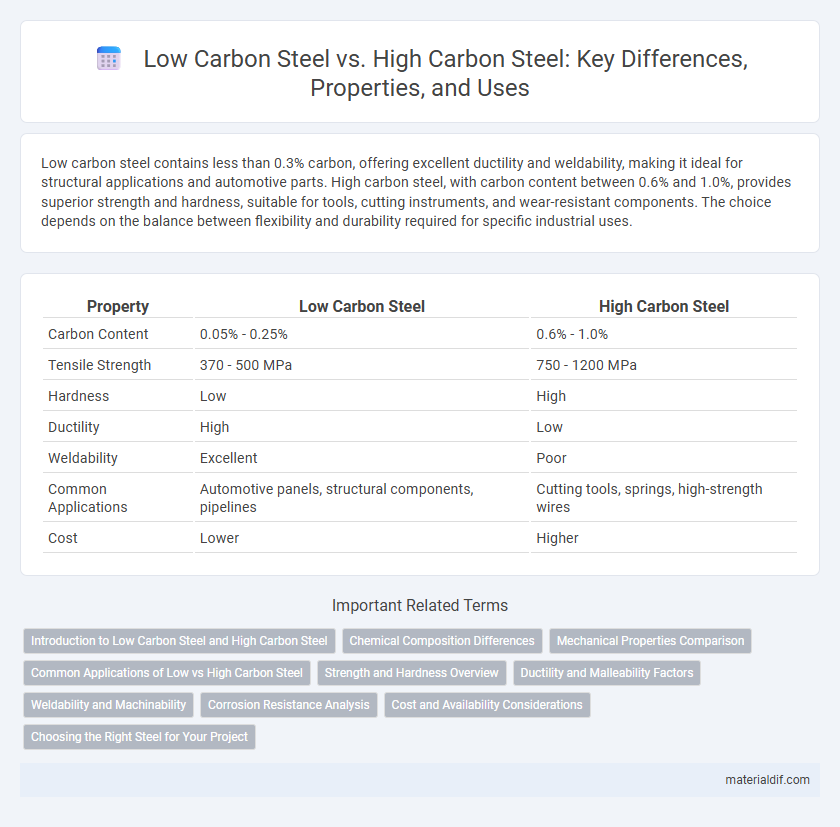

Low carbon steel contains less than 0.3% carbon, offering excellent ductility and weldability, making it ideal for structural applications and automotive parts. High carbon steel, with carbon content between 0.6% and 1.0%, provides superior strength and hardness, suitable for tools, cutting instruments, and wear-resistant components. The choice depends on the balance between flexibility and durability required for specific industrial uses.

Table of Comparison

| Property | Low Carbon Steel | High Carbon Steel |

|---|---|---|

| Carbon Content | 0.05% - 0.25% | 0.6% - 1.0% |

| Tensile Strength | 370 - 500 MPa | 750 - 1200 MPa |

| Hardness | Low | High |

| Ductility | High | Low |

| Weldability | Excellent | Poor |

| Common Applications | Automotive panels, structural components, pipelines | Cutting tools, springs, high-strength wires |

| Cost | Lower | Higher |

Introduction to Low Carbon Steel and High Carbon Steel

Low carbon steel contains approximately 0.05% to 0.25% carbon, making it softer and more ductile with excellent weldability, ideal for automotive body panels and structural shapes. High carbon steel has a carbon content ranging from 0.6% to 1.0%, resulting in higher hardness, strength, and wear resistance, commonly used for cutting tools, springs, and high-strength wires. The distinct carbon levels directly influence mechanical properties and suitability for various industrial applications.

Chemical Composition Differences

Low carbon steel contains approximately 0.05% to 0.25% carbon, making it more malleable and ductile, while high carbon steel ranges from 0.6% to 1.0% carbon, providing increased hardness and tensile strength. The low carbon content in mild steel retains higher amounts of iron and minimal alloying elements, resulting in easier welding and forming capabilities. In contrast, high carbon steel incorporates greater carbon concentration, often accompanied by small amounts of manganese and silicon, enhancing wear resistance and strength but reducing flexibility.

Mechanical Properties Comparison

Low carbon steel typically contains less than 0.3% carbon, offering high ductility, ease of welding, and excellent toughness, making it ideal for structural applications requiring flexibility. High carbon steel, with carbon content ranging from 0.6% to 1.0%, exhibits significantly higher hardness, tensile strength, and wear resistance, but reduced ductility and weldability. The choice between low and high carbon steel directly impacts mechanical performance, balancing strength and malleability for specific engineering needs.

Common Applications of Low vs High Carbon Steel

Low carbon steel, known for its ductility and weldability, is commonly used in construction materials, automotive panels, and household appliances where flexibility and ease of fabrication are essential. High carbon steel, offering superior hardness and tensile strength, finds applications in cutting tools, springs, and high-strength wires that require durability and wear resistance. These distinct properties make low carbon steel ideal for structural components, while high carbon steel suits heavy-duty mechanical parts.

Strength and Hardness Overview

Low carbon steel typically contains less than 0.3% carbon, offering lower strength and hardness but greater ductility and weldability suitable for structural applications. High carbon steel, with carbon content ranging from 0.6% to 1.0%, provides significantly increased tensile strength and hardness, making it ideal for tools, knives, and high-stress mechanical components. The difference in carbon content directly influences the steel's microstructure, with high carbon steel forming more cementite, resulting in superior hardness and wear resistance compared to low carbon variants.

Ductility and Malleability Factors

Low carbon steel exhibits higher ductility and malleability compared to high carbon steel due to its lower carbon content, typically below 0.3%. This allows low carbon steel to undergo significant plastic deformation without fracturing, making it ideal for forming and bending applications. In contrast, high carbon steel, with carbon content above 0.6%, offers increased hardness and strength but reduced ductility and malleability, limiting its ability to deform without cracking.

Weldability and Machinability

Low carbon steel offers superior weldability due to its lower carbon content, reducing the risk of cracking and distortion during welding processes. High carbon steel, while stronger and harder, presents challenges in weldability and requires preheating and post-weld heat treatment to prevent brittleness. Machinability is generally better in low carbon steel because it is softer and less abrasive to cutting tools, whereas high carbon steel's hardness increases tool wear and machining difficulty.

Corrosion Resistance Analysis

Low carbon steel typically exhibits better corrosion resistance due to its lower carbon content, which reduces the formation of brittle carbides and enhances the steel's ability to form a stable oxide layer. High carbon steel, with increased carbon content up to 2%, tends to have reduced corrosion resistance as the higher carbon facilitates carbide precipitation, resulting in microstructural heterogeneity and increased susceptibility to rust. The corrosion resistance differences directly impact applications, with low carbon steel favored in environments with higher moisture and corrosive agents, while high carbon steel is used where hardness and wear resistance outweigh corrosion concerns.

Cost and Availability Considerations

Low carbon steel is generally more cost-effective and widely available due to its simpler manufacturing process and abundant raw materials. High carbon steel, while offering superior hardness and strength, tends to be more expensive and less readily available because of the additional alloying elements and specialized processing required. Choosing between these steels depends on balancing budget constraints with the mechanical property needs of the application.

Choosing the Right Steel for Your Project

Low carbon steel offers excellent weldability, ductility, and is ideal for projects requiring easy shaping and forming, such as automotive panels and structural components. High carbon steel provides superior hardness and tensile strength, making it suitable for cutting tools, springs, and heavy-duty machinery parts. Selecting the right steel depends on balancing strength requirements, machinability, and corrosion resistance to optimize project performance and longevity.

Low Carbon Steel vs High Carbon Steel Infographic

materialdif.com

materialdif.com