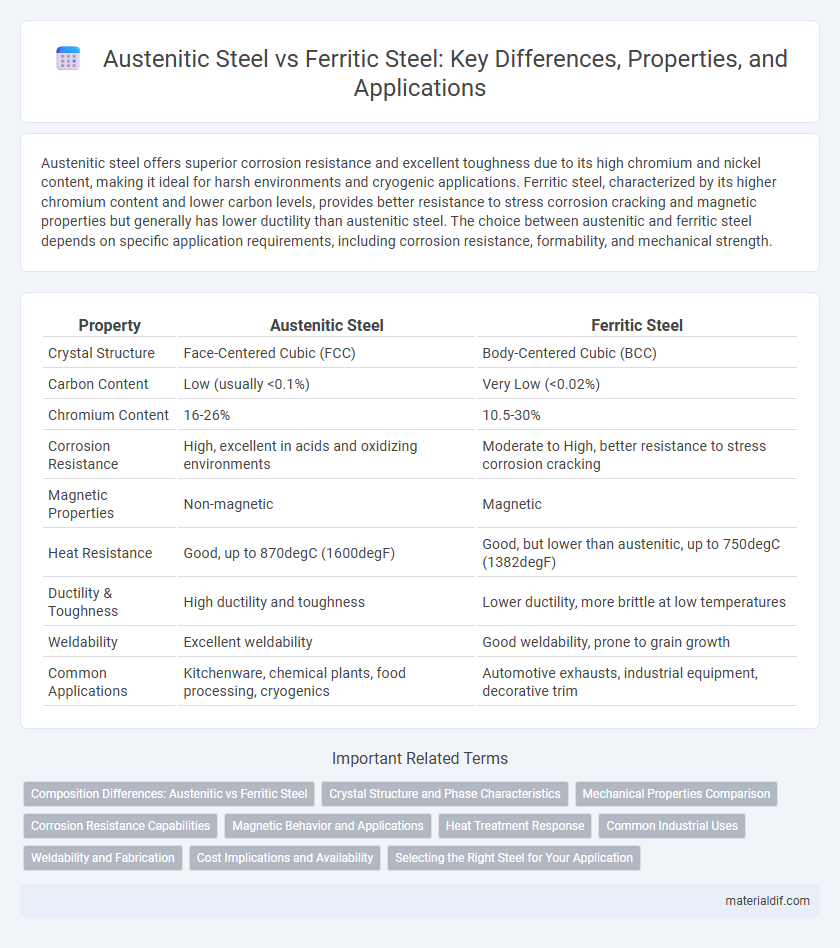

Austenitic steel offers superior corrosion resistance and excellent toughness due to its high chromium and nickel content, making it ideal for harsh environments and cryogenic applications. Ferritic steel, characterized by its higher chromium content and lower carbon levels, provides better resistance to stress corrosion cracking and magnetic properties but generally has lower ductility than austenitic steel. The choice between austenitic and ferritic steel depends on specific application requirements, including corrosion resistance, formability, and mechanical strength.

Table of Comparison

| Property | Austenitic Steel | Ferritic Steel |

|---|---|---|

| Crystal Structure | Face-Centered Cubic (FCC) | Body-Centered Cubic (BCC) |

| Carbon Content | Low (usually <0.1%) | Very Low (<0.02%) |

| Chromium Content | 16-26% | 10.5-30% |

| Corrosion Resistance | High, excellent in acids and oxidizing environments | Moderate to High, better resistance to stress corrosion cracking |

| Magnetic Properties | Non-magnetic | Magnetic |

| Heat Resistance | Good, up to 870degC (1600degF) | Good, but lower than austenitic, up to 750degC (1382degF) |

| Ductility & Toughness | High ductility and toughness | Lower ductility, more brittle at low temperatures |

| Weldability | Excellent weldability | Good weldability, prone to grain growth |

| Common Applications | Kitchenware, chemical plants, food processing, cryogenics | Automotive exhausts, industrial equipment, decorative trim |

Composition Differences: Austenitic vs Ferritic Steel

Austenitic steel contains high levels of chromium (16-26%) and nickel (6-22%), which stabilizes the face-centered cubic (FCC) structure, providing excellent corrosion resistance and ductility. Ferritic steel primarily consists of chromium (10.5-27%) with minimal nickel content, resulting in a body-centered cubic (BCC) structure that offers good resistance to stress corrosion cracking but lower toughness compared to austenitic grades. The distinct alloying elements and crystal structures dictate their mechanical properties and applications, with austenitic steels favored for their formability and ferritic steels preferred for high-temperature environments.

Crystal Structure and Phase Characteristics

Austenitic steel features a face-centered cubic (FCC) crystal structure that provides excellent ductility and corrosion resistance due to its non-magnetic phase stability at room temperature. Ferritic steel, with its body-centered cubic (BCC) crystal structure, exhibits higher thermal conductivity and magnetic properties but lower ductility compared to austenitic steel. The phase characteristics of austenitic steel remain stable across a wide temperature range, while ferritic steel transitions into a more brittle phase at low temperatures, impacting its mechanical performance.

Mechanical Properties Comparison

Austenitic steel exhibits high ductility, excellent toughness, and superior corrosion resistance due to its face-centered cubic (FCC) crystal structure, making it ideal for applications requiring high strength and formability. Ferritic steel, characterized by a body-centered cubic (BCC) structure, offers good resistance to stress corrosion cracking and better thermal conductivity but generally has lower tensile strength and ductility compared to austenitic grades. Mechanical properties of austenitic steel include tensile strengths ranging from 515 to 830 MPa and elongation values above 40%, whereas ferritic steel typically shows tensile strengths between 350 and 700 MPa with elongation around 20-30%.

Corrosion Resistance Capabilities

Austenitic steel exhibits superior corrosion resistance due to its high chromium and nickel content, forming a stable oxide layer that protects against oxidation and pitting in harsh environments. Ferritic steel, with lower nickel and higher chromium levels, offers moderate corrosion resistance but is more susceptible to stress corrosion cracking and is less effective in chloride-rich conditions. The enhanced corrosion resistance of austenitic steel makes it ideal for chemical processing, marine applications, and environments demanding long-term durability.

Magnetic Behavior and Applications

Austenitic steel exhibits non-magnetic properties due to its face-centered cubic (FCC) crystal structure, making it ideal for applications in cryogenic vessels, chemical processing equipment, and medical devices where corrosion resistance and non-magnetic behavior are critical. Ferritic steel, with a body-centered cubic (BCC) structure, demonstrates magnetic behavior and is commonly used in automotive parts, kitchen utensils, and structural components where magnetism and moderate corrosion resistance are advantageous. The distinct magnetic properties of austenitic and ferritic steels directly influence their suitability across industries requiring specific magnetic responses and mechanical performance.

Heat Treatment Response

Austenitic steel exhibits excellent heat treatment response with high resistance to hardening and maintains its toughness and corrosion resistance after annealing and solution treatment. Ferritic steel shows limited heat treatment response due to its low carbon content, primarily relying on stress relief annealing to enhance ductility and reduce brittleness. The differing microstructures, face-centered cubic in austenitic and body-centered cubic in ferritic steels, drive their distinct thermal and mechanical behavior during heat treatment processes.

Common Industrial Uses

Austenitic steel is widely used in the food processing, chemical, and pharmaceutical industries due to its excellent corrosion resistance and ease of fabrication. Ferritic steel finds common applications in automotive exhaust systems, industrial equipment, and kitchen utensils because of its good thermal conductivity and resistance to stress corrosion cracking. Both types of steel serve critical roles in industries requiring specific mechanical and chemical properties.

Weldability and Fabrication

Austenitic steel exhibits superior weldability due to its high ductility and resistance to cracking, making it ideal for complex fabrications and heavy industrial applications. Ferritic steel, while less weldable because of its lower ductility and tendency to grain growth during welding, offers good formability and is suitable for automotive and construction uses. Both types require specific welding techniques and filler materials to optimize joint integrity and minimize stress corrosion in fabricated structures.

Cost Implications and Availability

Austenitic steel typically incurs higher production costs due to its complex alloy composition with higher nickel content, making it more expensive than ferritic steel which relies mainly on chromium and iron. Ferritic steel is widely available and generally more cost-effective, benefitting industries with budget constraints requiring moderate corrosion resistance. The economic feasibility of using each steel type depends on balancing long-term durability and upfront material costs relative to application demands.

Selecting the Right Steel for Your Application

Austenitic steel offers excellent corrosion resistance and high ductility, making it ideal for applications in harsh environments such as chemical processing and food industries. Ferritic steel provides good stress corrosion resistance and magnetic properties, suitable for automotive exhaust systems and structural components. Selecting the right steel depends on factors like corrosion resistance requirements, mechanical properties, and application conditions, ensuring optimal performance and longevity.

Austenitic steel vs Ferritic steel Infographic

materialdif.com

materialdif.com