Spring steel offers exceptional elasticity and fatigue resistance, making it ideal for components that require repeated flexing such as springs and clips. Bearing steel features high hardness and wear resistance, which enhances its performance in demanding applications like ball bearings and rolling elements. Choosing between spring steel and bearing steel depends on balancing the need for flexibility versus durability under continuous stress and load.

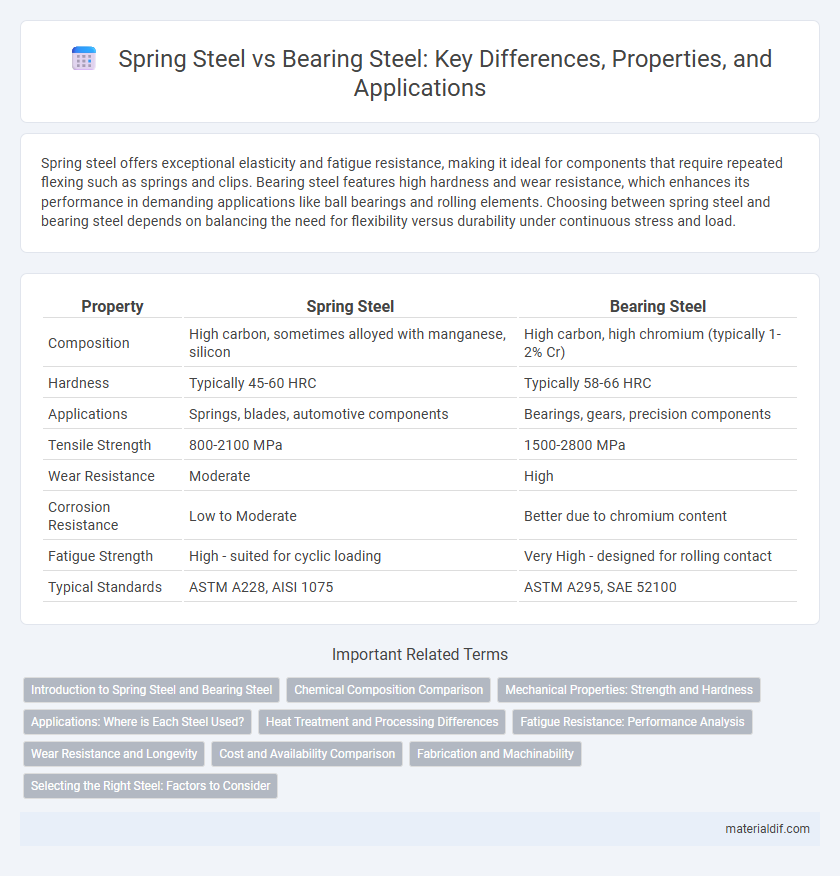

Table of Comparison

| Property | Spring Steel | Bearing Steel |

|---|---|---|

| Composition | High carbon, sometimes alloyed with manganese, silicon | High carbon, high chromium (typically 1-2% Cr) |

| Hardness | Typically 45-60 HRC | Typically 58-66 HRC |

| Applications | Springs, blades, automotive components | Bearings, gears, precision components |

| Tensile Strength | 800-2100 MPa | 1500-2800 MPa |

| Wear Resistance | Moderate | High |

| Corrosion Resistance | Low to Moderate | Better due to chromium content |

| Fatigue Strength | High - suited for cyclic loading | Very High - designed for rolling contact |

| Typical Standards | ASTM A228, AISI 1075 | ASTM A295, SAE 52100 |

Introduction to Spring Steel and Bearing Steel

Spring steel exhibits high yield strength and excellent elasticity, making it ideal for components such as springs, clips, and retainer plates that require repeated flexing without deformation. Bearing steel, characterized by its high hardness, wear resistance, and fatigue strength, is specifically engineered for rolling elements like balls and rollers within bearings to ensure durability under heavy loads. Both materials undergo specialized heat treatments to enhance their mechanical properties, with spring steel focusing on flexibility and bearing steel on hardness and wear resistance.

Chemical Composition Comparison

Spring steel primarily consists of carbon (0.5%-1.0%) and manganese (0.7%-1.2%), providing high tensile strength and flexibility essential for spring performance. Bearing steel, such as AISI 52100, contains approximately 1.0%-1.1% carbon and 1.4%-1.6% chromium, enhancing hardness and wear resistance critical for bearing applications. The higher chromium content in bearing steel distinguishes it from spring steel, contributing to superior corrosion resistance and fatigue life.

Mechanical Properties: Strength and Hardness

Spring steel exhibits exceptional tensile strength and high elasticity, making it ideal for applications requiring resistance to deformation under cyclic loading. Bearing steel, characterized by superior hardness and wear resistance, is engineered to withstand heavy loads and reduce surface fatigue in rolling elements. The mechanical properties of spring steel prioritize flexibility and durability, whereas bearing steel emphasizes maximum hardness and load-bearing capacity.

Applications: Where is Each Steel Used?

Spring steel is primarily used in applications requiring high elasticity and fatigue resistance, such as automotive suspension springs, clip fasteners, and industrial machinery components. Bearing steel is employed in manufacturing rolling element bearings, gears, and other precision components that demand exceptional hardness, wear resistance, and dimensional stability. Both steels serve critical roles in mechanical systems but are optimized for different performance criteria based on their specific alloy compositions and heat treatments.

Heat Treatment and Processing Differences

Spring steel undergoes quenching and tempering to achieve high elasticity and fatigue resistance, making it ideal for components like springs and clips. Bearing steel, typically high-carbon chromium alloy, is through-hardened and case-hardened for exceptional wear resistance and hardness, suitable for rolling elements in bearings. The heat treatment of spring steel emphasizes flexibility, while bearing steel processing prioritizes surface hardness and dimensional stability under heavy loads.

Fatigue Resistance: Performance Analysis

Spring steel exhibits exceptional fatigue resistance due to its high yield strength and ability to withstand repeated cyclic stress without permanent deformation, making it ideal for applications like suspension systems and springs. Bearing steel, typically containing higher carbon and chromium levels, offers superior hardness and wear resistance but may present lower fatigue resistance under extreme cyclic loading conditions compared to spring steel. Performance analysis shows that while bearing steel excels in durability against surface fatigue and contact stress, spring steel provides more consistent resilience in dynamic, high-frequency fatigue environments.

Wear Resistance and Longevity

Spring steel exhibits excellent wear resistance due to its high carbon content and ability to withstand repeated stress without deformation, making it ideal for applications requiring durability under cyclic loads. Bearing steel is specifically engineered for superior wear resistance and longevity by incorporating elements like chromium, enhancing hardness and resistance to fatigue in high-contact environments. The optimized microstructure of bearing steel ensures prolonged service life and reliable performance in rolling element bearings, surpassing the wear resistance characteristics of standard spring steel.

Cost and Availability Comparison

Spring steel generally offers greater availability and lower cost compared to bearing steel due to its widespread use in automotive and industrial applications. Bearing steel, known for its superior hardness and wear resistance, commands higher prices and faces more limited availability because of stricter alloying and heat treatment requirements. Manufacturers seeking budget-friendly options with adequate performance typically opt for spring steel, while high-precision bearing components necessitate investing in premium bearing steel grades.

Fabrication and Machinability

Spring steel exhibits excellent flexibility and fatigue resistance, making it ideal for components requiring high elasticity and repeated stress cycles, with moderate machinability suited for forming processes like coiling and bending. Bearing steel, characterized by its high hardness and wear resistance due to elevated carbon and chromium content, demands precision machining and heat treatment to achieve optimal surface finish and dimensional accuracy for rotating applications. Fabrication of bearing steel involves stringent control of machining parameters to prevent tool wear and ensure structural integrity, while spring steel allows easier cold working but requires careful handling to maintain its mechanical properties.

Selecting the Right Steel: Factors to Consider

When selecting between spring steel and bearing steel, consider factors such as tensile strength, fatigue resistance, and application-specific load requirements. Spring steel offers excellent elasticity and high fatigue life for dynamic and repetitive stresses, making it ideal for springs and resilient components. Bearing steel, characterized by high hardness and wear resistance, is optimized for rolling elements subjected to heavy loads and continuous contact.

Spring steel vs Bearing steel Infographic

materialdif.com

materialdif.com