Maraging steel offers superior strength and toughness due to its aging heat treatment, resulting in low carbon content and enhanced machinability compared to martensitic steel. Martensitic steel, characterized by higher carbon levels, provides excellent hardness and wear resistance but can be more brittle and challenging to machine. Choosing between the two depends on the application's need for either ultimate strength and ductility (maraging) or hardness and abrasion resistance (martensitic).

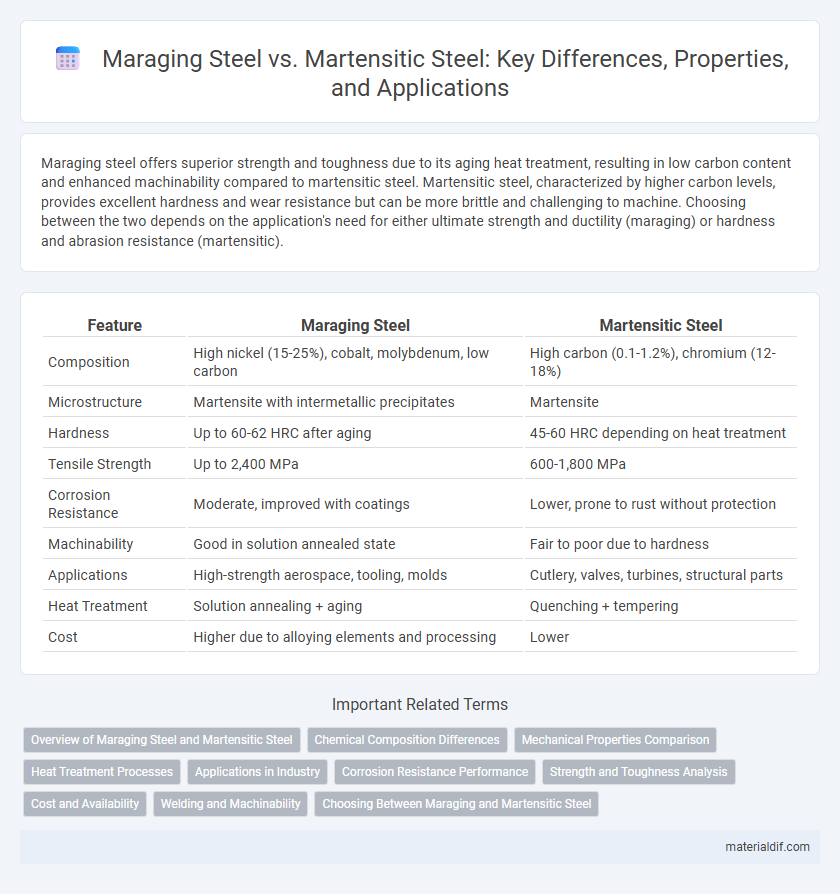

Table of Comparison

| Feature | Maraging Steel | Martensitic Steel |

|---|---|---|

| Composition | High nickel (15-25%), cobalt, molybdenum, low carbon | High carbon (0.1-1.2%), chromium (12-18%) |

| Microstructure | Martensite with intermetallic precipitates | Martensite |

| Hardness | Up to 60-62 HRC after aging | 45-60 HRC depending on heat treatment |

| Tensile Strength | Up to 2,400 MPa | 600-1,800 MPa |

| Corrosion Resistance | Moderate, improved with coatings | Lower, prone to rust without protection |

| Machinability | Good in solution annealed state | Fair to poor due to hardness |

| Applications | High-strength aerospace, tooling, molds | Cutlery, valves, turbines, structural parts |

| Heat Treatment | Solution annealing + aging | Quenching + tempering |

| Cost | Higher due to alloying elements and processing | Lower |

Overview of Maraging Steel and Martensitic Steel

Maraging steel is a high-strength alloy composed primarily of iron, nickel, cobalt, and molybdenum, known for its exceptional toughness and easy machinability due to precipitation hardening. Martensitic steel, characterized by its carbon-rich iron composition, achieves high hardness and strength through heat treatment processes that transform its microstructure into martensite. Both steels are widely used in aerospace and tooling industries, with maraging steel excelling in applications requiring superior fracture toughness and martensitic steel favored for wear resistance and hardness.

Chemical Composition Differences

Maraging steel contains high levels of nickel, typically 15-25%, along with cobalt, molybdenum, and titanium, which contribute to its exceptional strength and toughness without carbon. In contrast, martensitic steel has a higher carbon content, usually between 0.1-1.2%, with significant amounts of chromium but minimal nickel, enabling hardenability and wear resistance through heat treatment. The presence of alloying elements like cobalt and titanium in maraging steel differentiates its microstructure and mechanical properties from the carbon-rich martensitic steels.

Mechanical Properties Comparison

Maraging steel exhibits superior tensile strength ranging from 1400 to 2500 MPa and exceptional toughness due to its low carbon content and age-hardening process. Martensitic steel offers moderate tensile strength around 500 to 1200 MPa but generally has higher hardness and wear resistance attributable to its carbon-rich composition and quenching heat treatment. The enhanced mechanical properties of maraging steel include excellent ductility and impact resistance, making it preferable for aerospace and high-performance applications compared to the more brittle and less ductile martensitic steel.

Heat Treatment Processes

Maraging steel undergoes a solution annealing process followed by aging at 480-500degC to achieve superior strength and toughness through precipitation hardening, while martensitic steel is typically heat treated by quenching from austenitizing temperature and then tempering to balance hardness and ductility. The aging process in maraging steel allows for controlled formation of intermetallic compounds, enhancing mechanical properties without sacrificing malleability. Martensitic steel's rapid quenching forms a hard, brittle structure which is subsequently tempered to reduce internal stresses and improve toughness.

Applications in Industry

Maraging steel is extensively used in aerospace and tooling industries due to its superior strength, toughness, and ease of machining, making it ideal for high-performance aerospace components, molds, and dies. Martensitic steel finds widespread applications in cutlery, surgical instruments, and automotive parts, valued for its hardness, wear resistance, and ability to be heat treated for enhanced mechanical properties. Both steels serve critical roles in manufacturing but are selected based on specific requirements for strength, toughness, and corrosion resistance in industrial applications.

Corrosion Resistance Performance

Maraging steel exhibits superior corrosion resistance compared to martensitic steel due to its low carbon content and the presence of nickel and cobalt, which enhance its ability to withstand oxidation and environmental degradation. Martensitic steel, with higher carbon levels, is more prone to corrosion and requires additional surface treatments or coatings to improve durability in corrosive environments. The intrinsic microstructure of maraging steel, characterized by precipitation strengthening, further contributes to its resilience against rust and pitting corrosion in marine and industrial applications.

Strength and Toughness Analysis

Maraging steel exhibits superior strength due to its ultra-high tensile properties achieved through age-hardening, often reaching tensile strengths above 2,000 MPa while maintaining exceptional toughness and ductility. In contrast, martensitic steel offers high hardness and strength from its quenched and tempered microstructure but generally sacrifices some toughness, making it more brittle under impact. The balance of strength and toughness in maraging steel outperforms martensitic steel, making it ideal for aerospace and tooling applications where both mechanical properties are critical.

Cost and Availability

Maraging steel typically costs significantly more than martensitic steel due to its complex alloy composition and specialized heat treatment processes. Martensitic steel is widely available and more affordable, making it a preferred choice for applications requiring moderate strength and hardness. The high cost and limited availability of maraging steel often restrict its use to aerospace and high-performance engineering sectors.

Welding and Machinability

Maraging steel exhibits superior weldability compared to martensitic steel due to its low carbon content, reducing the risk of cracking during welding processes. Machinability is generally higher in maraging steel, which allows for smoother cutting and less tool wear, whereas martensitic steel's higher hardness can lead to increased tool degradation and machining difficulties. These differences make maraging steel more suitable for applications requiring precise welding and efficient machining.

Choosing Between Maraging and Martensitic Steel

Choosing between maraging steel and martensitic steel depends on the required combination of strength, toughness, and machinability for specific applications. Maraging steel offers superior strength and toughness due to its unique nickel-rich composition and age-hardening process, making it ideal for aerospace and tooling industries. Martensitic steel provides high hardness and wear resistance through carbon-induced transformations, commonly used in cutlery, injection molds, and structural components where hardness and corrosion resistance are critical.

Maraging Steel vs Martensitic Steel Infographic

materialdif.com

materialdif.com