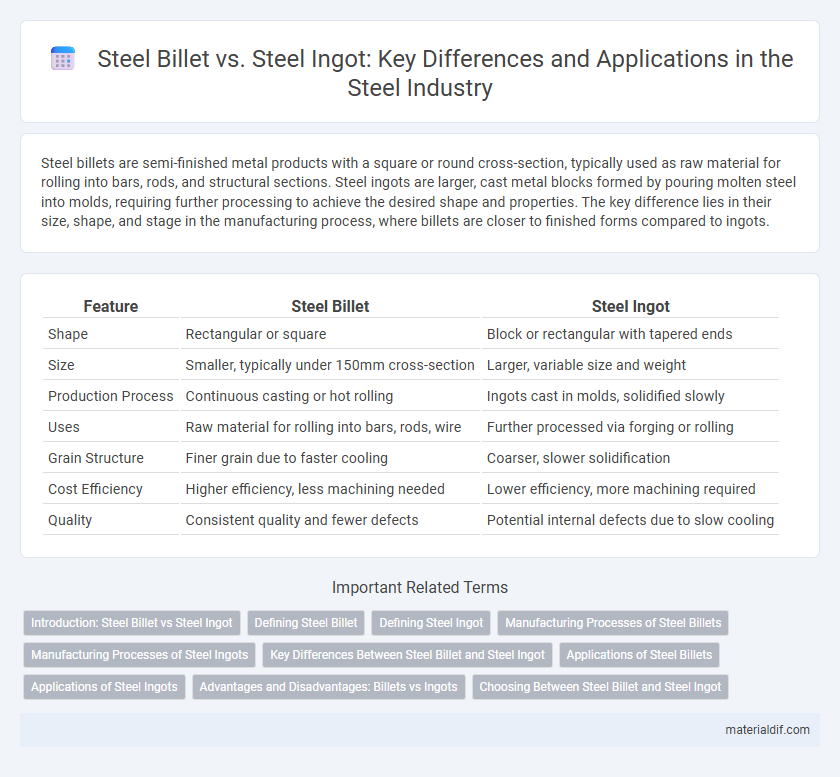

Steel billets are semi-finished metal products with a square or round cross-section, typically used as raw material for rolling into bars, rods, and structural sections. Steel ingots are larger, cast metal blocks formed by pouring molten steel into molds, requiring further processing to achieve the desired shape and properties. The key difference lies in their size, shape, and stage in the manufacturing process, where billets are closer to finished forms compared to ingots.

Table of Comparison

| Feature | Steel Billet | Steel Ingot |

|---|---|---|

| Shape | Rectangular or square | Block or rectangular with tapered ends |

| Size | Smaller, typically under 150mm cross-section | Larger, variable size and weight |

| Production Process | Continuous casting or hot rolling | Ingots cast in molds, solidified slowly |

| Uses | Raw material for rolling into bars, rods, wire | Further processed via forging or rolling |

| Grain Structure | Finer grain due to faster cooling | Coarser, slower solidification |

| Cost Efficiency | Higher efficiency, less machining needed | Lower efficiency, more machining required |

| Quality | Consistent quality and fewer defects | Potential internal defects due to slow cooling |

Introduction: Steel Billet vs Steel Ingot

Steel billets are semi-finished steel products characterized by smaller cross-sections, typically square or rectangular, used primarily in rolling or forging processes. Steel ingots are larger cast blocks formed by pouring molten steel into molds, serving as the initial raw material for further shaping and refining. Understanding the differences between billets and ingots is essential for optimizing steel production efficiency and end-product quality.

Defining Steel Billet

Steel billets are semi-finished steel products with a square or rectangular cross-section, typically measuring less than 150 mm in thickness. They are produced by continuous casting or hot rolling of steel ingots and serve as raw material for manufacturing bars, rods, and wire products. Steel billets have a more uniform composition and smaller cross-section compared to steel ingots, enabling easier processing in downstream rolling mills.

Defining Steel Ingot

A steel ingot is a large, solid piece of steel formed by pouring molten metal into a mold, allowing it to cool and solidify into a manageable shape for further processing. Unlike steel billets, which are semi-finished products with uniform dimensions typically used for rolling or forging, steel ingots serve as the primary raw material in steel manufacturing. Steel ingots contain impurities and inclusions that are reduced during subsequent refining and shaping processes, ensuring the desired mechanical properties in the final product.

Manufacturing Processes of Steel Billets

Steel billets are produced through continuous casting or hot rolling processes that transform molten steel into semi-finished solid forms with a uniform square or rectangular cross-section, optimized for further shaping and manufacturing. In contrast to steel ingots, billets offer enhanced mechanical properties and dimensional consistency due to controlled cooling rates and deformation during billet rolling. Advanced billet manufacturing incorporates secondary refining and vacuum degassing to improve purity and structural integrity, crucial for high-performance steel applications.

Manufacturing Processes of Steel Ingots

Steel ingots are produced by pouring molten steel into molds, where it solidifies through controlled cooling to reduce internal stresses and achieve uniform grain structure. This casting process involves stages like melting, refining, and solidification, often followed by reheating before further shaping operations. Ingots serve as the primary raw material for subsequent rolling, forging, or extrusion to form billets and other semi-finished steel products.

Key Differences Between Steel Billet and Steel Ingot

Steel billets and steel ingots differ primarily in shape and production process, with billets typically being smaller, semi-finished rectangular or square bars, and ingots larger, irregularly shaped blocks cast directly from molten steel. Billets undergo further processing such as rolling or extrusion to produce finished products like bars and rods, while ingots serve as the initial raw form that requires extensive reheating and shaping. The higher uniformity and mechanical properties of billets make them preferable for manufacturing precision steel components compared to ingots.

Applications of Steel Billets

Steel billets serve as the fundamental raw material in manufacturing long products such as bars, rods, and tubes due to their uniform cross-section and excellent mechanical properties. Their versatility makes them ideal for applications in construction, automotive components, and machinery parts where strength and precision are critical. Unlike steel ingots, billets undergo further processing like rolling or extrusion, enhancing their suitability for diverse industrial applications.

Applications of Steel Ingots

Steel ingots are primarily used in heavy industrial applications requiring large, solid metal forms for further shaping or processing, such as forging, rolling, and extrusion in the production of structural components and heavy machinery parts. Their substantial size and uniform composition make them ideal for manufacturing large steel parts like gears, crankshafts, and shipbuilding elements. In contrast to billets, steel ingots offer versatility in creating custom shapes and high-strength products for aerospace and automotive industries.

Advantages and Disadvantages: Billets vs Ingots

Steel billets offer greater uniformity and dimensional accuracy compared to ingots, enabling more precise manufacturing processes and better surface finish. Ingots allow for larger initial casting sizes, which can be advantageous for heavy, large-scale steel products but often require extensive reheating and rolling, increasing energy consumption. Billets typically have fewer internal defects and lower porosity, resulting in improved mechanical properties, while ingots may suffer from segregation and variable grain structure affecting material consistency.

Choosing Between Steel Billet and Steel Ingot

Choosing between steel billet and steel ingot depends on the desired manufacturing process and final product requirements. Steel billets, characterized by their smaller cross-section and uniform composition, are ideal for rolling and forging operations that demand consistent mechanical properties. Steel ingots, larger in size and requiring additional processing, suit applications where customized shapes and sizes are essential before further refinement.

Steel Billet vs Steel Ingot Infographic

materialdif.com

materialdif.com