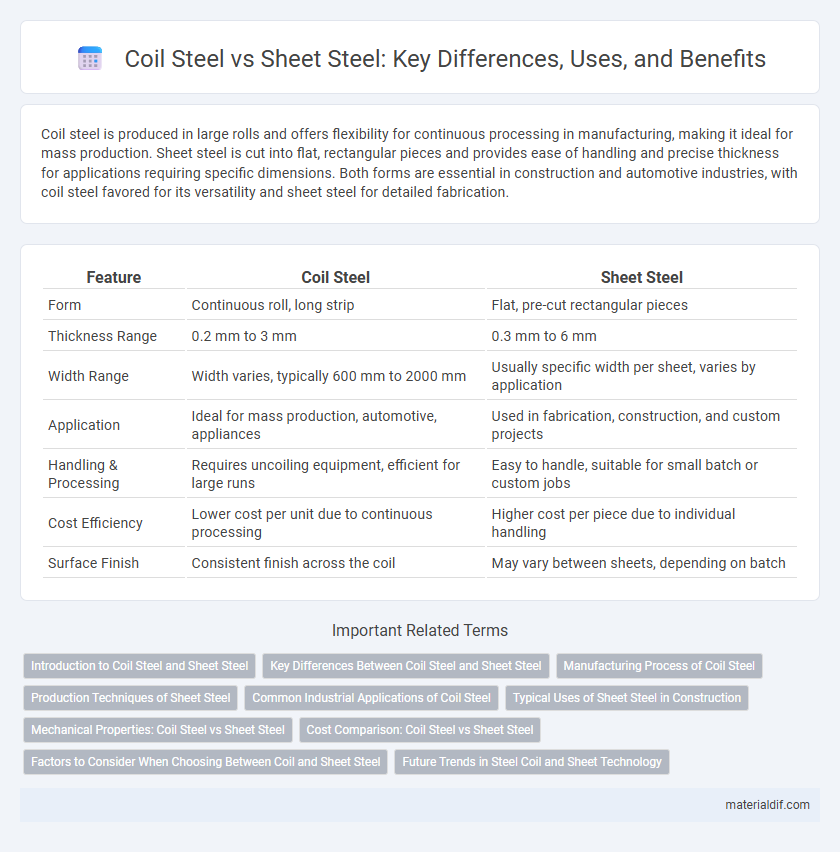

Coil steel is produced in large rolls and offers flexibility for continuous processing in manufacturing, making it ideal for mass production. Sheet steel is cut into flat, rectangular pieces and provides ease of handling and precise thickness for applications requiring specific dimensions. Both forms are essential in construction and automotive industries, with coil steel favored for its versatility and sheet steel for detailed fabrication.

Table of Comparison

| Feature | Coil Steel | Sheet Steel |

|---|---|---|

| Form | Continuous roll, long strip | Flat, pre-cut rectangular pieces |

| Thickness Range | 0.2 mm to 3 mm | 0.3 mm to 6 mm |

| Width Range | Width varies, typically 600 mm to 2000 mm | Usually specific width per sheet, varies by application |

| Application | Ideal for mass production, automotive, appliances | Used in fabrication, construction, and custom projects |

| Handling & Processing | Requires uncoiling equipment, efficient for large runs | Easy to handle, suitable for small batch or custom jobs |

| Cost Efficiency | Lower cost per unit due to continuous processing | Higher cost per piece due to individual handling |

| Surface Finish | Consistent finish across the coil | May vary between sheets, depending on batch |

Introduction to Coil Steel and Sheet Steel

Coil steel consists of long, continuous strips of metal rolled into coils, allowing for efficient storage and transportation, and is primarily used in industries requiring large-scale metal fabrication. Sheet steel, cut into flat, rectangular pieces of various thicknesses, is widely utilized in construction, automotive, and appliance manufacturing for its versatility and ease of handling. Both coil steel and sheet steel serve critical roles in manufacturing, with coil steel favored for processing flexibility and sheet steel for direct application.

Key Differences Between Coil Steel and Sheet Steel

Coil steel consists of long strips of steel wound into a roll, allowing for efficient transportation and continuous processing, whereas sheet steel refers to flat, rectangular pieces cut to specific sizes. Coil steel typically offers greater flexibility for manufacturing applications requiring continuous feeding, while sheet steel is preferred for projects needing precise dimensional cuts and flat surfaces. The choice between coil and sheet steel impacts production efficiency, material handling, and suitability for various industrial uses such as automotive, construction, and appliance manufacturing.

Manufacturing Process of Coil Steel

Coil steel is produced through a continuous rolling process where hot or cold steel slabs are passed through rollers and then coiled into large rolls for easier handling and transportation. This manufacturing method enhances uniform thickness and surface quality compared to individual sheet steel cutting. The coil steel is often further processed into sheets or strips based on application requirements, offering versatility in steel fabrication industries.

Production Techniques of Sheet Steel

Sheet steel production primarily involves hot rolling and cold rolling processes, where hot rolling shapes steel at high temperatures, enhancing workability, while cold rolling refines surface finish and dimensional accuracy. Annealing treatments follow cold rolling to improve ductility and relieve internal stresses. These production techniques result in uniform thickness and superior mechanical properties, differentiating sheet steel from coil steel, which is typically supplied in coiled form for further processing.

Common Industrial Applications of Coil Steel

Coil steel is widely used in the automotive industry for manufacturing body panels due to its uniform thickness and high strength. Construction industries utilize coil steel for roofing, siding, and structural components, benefiting from its ease of transport and versatility. Additionally, coil steel is essential in appliance production, enabling efficient fabrication of durable and lightweight parts.

Typical Uses of Sheet Steel in Construction

Sheet steel is widely used in construction for roofing, wall cladding, and structural components due to its durability and ease of fabrication. Its versatility allows for applications in framing, ductwork, and interior paneling, providing strength and corrosion resistance. Sheet steel's ability to be cut and shaped precisely makes it ideal for custom architectural designs and protective surfaces.

Mechanical Properties: Coil Steel vs Sheet Steel

Coil steel exhibits superior tensile strength and uniformity compared to sheet steel due to its continuous rolling process, which enhances grain structure and mechanical consistency. Sheet steel, often produced from cut segments of coil steel, may have slightly lower yield strength and ductility because of the potential introduction of stresses during cutting and handling. The choice between coil and sheet steel impacts performance in applications requiring precise mechanical properties such as automotive body panels or structural components.

Cost Comparison: Coil Steel vs Sheet Steel

Coil steel generally offers a lower cost per unit than sheet steel due to its bulk packaging and reduced processing requirements, which translates to savings in storage and transportation. Sheet steel typically incurs higher expenses because it is cut to specific dimensions and often undergoes additional finishing processes, increasing labor and production costs. Manufacturers choose coil steel when large volumes and cost efficiency are priorities, while sheet steel is preferred for precision applications despite the higher price.

Factors to Consider When Choosing Between Coil and Sheet Steel

When choosing between coil steel and sheet steel, consider factors such as application requirements, material thickness, and processing methods. Coil steel offers advantages in continuous production and cost efficiency for large-scale manufacturing, while sheet steel provides precision and ease of handling for smaller or customized projects. The decision also depends on storage capabilities and the need for flexibility in fabrication processes.

Future Trends in Steel Coil and Sheet Technology

Future trends in steel coil and sheet technology emphasize enhanced strength-to-weight ratios through advanced alloy compositions and thermo-mechanical processing. Innovations in surface coating and treatment technologies improve corrosion resistance and paint adherence, critical for automotive and construction sectors. The integration of smart manufacturing and real-time quality monitoring systems enables precise control of dimensional tolerances and material properties, driving efficiency and sustainability in steel production.

Coil Steel vs Sheet Steel Infographic

materialdif.com

materialdif.com