Stainless steel offers superior corrosion resistance and durability compared to mild steel, making it ideal for environments exposed to moisture and chemicals. Mild steel is more cost-effective and easier to weld and machine, suitable for structural applications where corrosion resistance is not critical. Choosing between stainless steel and mild steel depends on the specific strength requirements, environmental conditions, and budget constraints of the project.

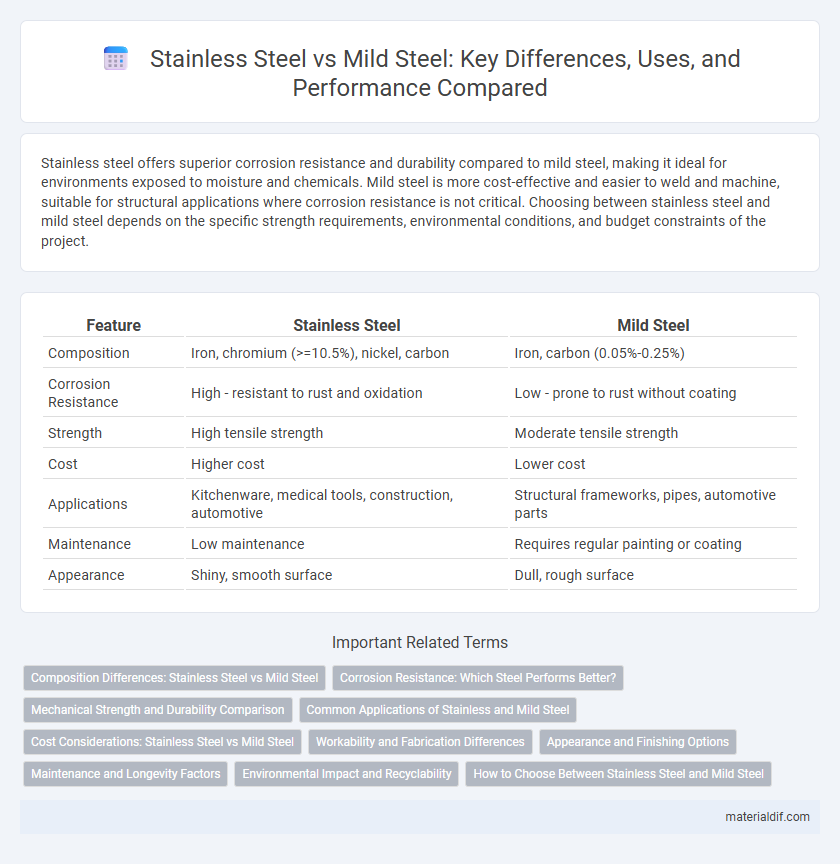

Table of Comparison

| Feature | Stainless Steel | Mild Steel |

|---|---|---|

| Composition | Iron, chromium (>=10.5%), nickel, carbon | Iron, carbon (0.05%-0.25%) |

| Corrosion Resistance | High - resistant to rust and oxidation | Low - prone to rust without coating |

| Strength | High tensile strength | Moderate tensile strength |

| Cost | Higher cost | Lower cost |

| Applications | Kitchenware, medical tools, construction, automotive | Structural frameworks, pipes, automotive parts |

| Maintenance | Low maintenance | Requires regular painting or coating |

| Appearance | Shiny, smooth surface | Dull, rough surface |

Composition Differences: Stainless Steel vs Mild Steel

Stainless steel contains a minimum of 10.5% chromium, which forms a passive layer to prevent corrosion, whereas mild steel primarily consists of iron with a carbon content of about 0.05% to 0.25%. The addition of elements like nickel, molybdenum, and manganese in stainless steel enhances its strength and corrosion resistance compared to mild steel. Mild steel's lower alloy content makes it more malleable and easier to weld but less resistant to rust and oxidation.

Corrosion Resistance: Which Steel Performs Better?

Stainless steel outperforms mild steel in corrosion resistance due to its chromium content, which forms a passive oxide layer protecting against rust and chemical damage. Mild steel, lacking this protective layer, is prone to oxidation and requires coatings or treatments for durability in corrosive environments. In applications involving moisture or chemicals, stainless steel ensures longer-lasting performance and reduced maintenance costs.

Mechanical Strength and Durability Comparison

Stainless steel exhibits superior mechanical strength and corrosion resistance compared to mild steel, making it ideal for applications requiring enhanced durability and longevity. Mild steel offers good tensile strength and is more malleable, but it is prone to rust and corrosion without protective coatings. The inherent chromium content in stainless steel forms a passive layer that provides exceptional durability in harsh environments, outperforming mild steel in mechanical robustness and lifespan.

Common Applications of Stainless and Mild Steel

Stainless steel is widely used in applications requiring corrosion resistance and aesthetic appeal, such as kitchen appliances, medical instruments, and architectural structures. Mild steel, known for its malleability and cost-effectiveness, is commonly employed in construction, automotive components, and manufacturing of machinery parts. Both materials serve distinct roles based on environmental exposure and mechanical requirements.

Cost Considerations: Stainless Steel vs Mild Steel

Mild steel is significantly more cost-effective than stainless steel, making it the preferred choice for budget-sensitive projects. Stainless steel, composed of higher alloy content such as chromium and nickel, commands a premium price due to its enhanced corrosion resistance and durability. The initial investment in stainless steel often justifies long-term savings in maintenance and replacement costs compared to mild steel.

Workability and Fabrication Differences

Stainless steel offers superior corrosion resistance and maintains strength at high temperatures, making it ideal for complex fabrication requiring welding, bending, and forming, though it demands specialized tools due to its hardness. Mild steel, with its lower carbon content, is easier to work with, allowing for straightforward cutting, welding, and shaping, making it cost-effective for mass production and simple fabrications. The trade-off lies in stainless steel's durability and finish quality versus mild steel's ease of machining and lower fabrication costs.

Appearance and Finishing Options

Stainless steel offers a naturally sleek, shiny appearance with excellent corrosion resistance, making it ideal for decorative applications and environments requiring durability. Mild steel, on the other hand, has a more matte, industrial look and requires coatings or paint to enhance its appearance and prevent rust. Finishing options for stainless steel include polishing, brushing, and passivation, while mild steel is commonly treated with galvanizing, powder coating, or painting to improve aesthetics and protection.

Maintenance and Longevity Factors

Stainless steel offers superior corrosion resistance and requires minimal maintenance, making it ideal for environments exposed to moisture or chemicals, while mild steel tends to rust and demands regular painting or coating to prevent degradation. The longevity of stainless steel significantly exceeds that of mild steel due to its chromium content, which forms a passive oxide layer protecting it from rust and wear. Mild steel's lower upfront cost is offset by higher long-term maintenance expenses and shorter lifespan, especially in outdoor or humid conditions.

Environmental Impact and Recyclability

Stainless steel offers superior recyclability due to its higher corrosion resistance, reducing waste and extending product lifespan compared to mild steel. Mild steel requires more frequent replacement and processing, leading to greater environmental impact through increased energy consumption and CO2 emissions. The sustainable production of stainless steel, leveraging its longevity and recyclability, makes it a more eco-friendly option in industrial applications.

How to Choose Between Stainless Steel and Mild Steel

Choosing between stainless steel and mild steel depends on the specific application requirements such as corrosion resistance, strength, and cost-effectiveness. Stainless steel offers superior corrosion resistance and durability, making it ideal for environments exposed to moisture or chemicals, whereas mild steel provides excellent weldability and is more affordable for structural and general engineering uses. Evaluating factors like environmental conditions, mechanical stress, and maintenance needs ensures the optimal selection between stainless steel and mild steel.

Stainless Steel vs Mild Steel Infographic

materialdif.com

materialdif.com