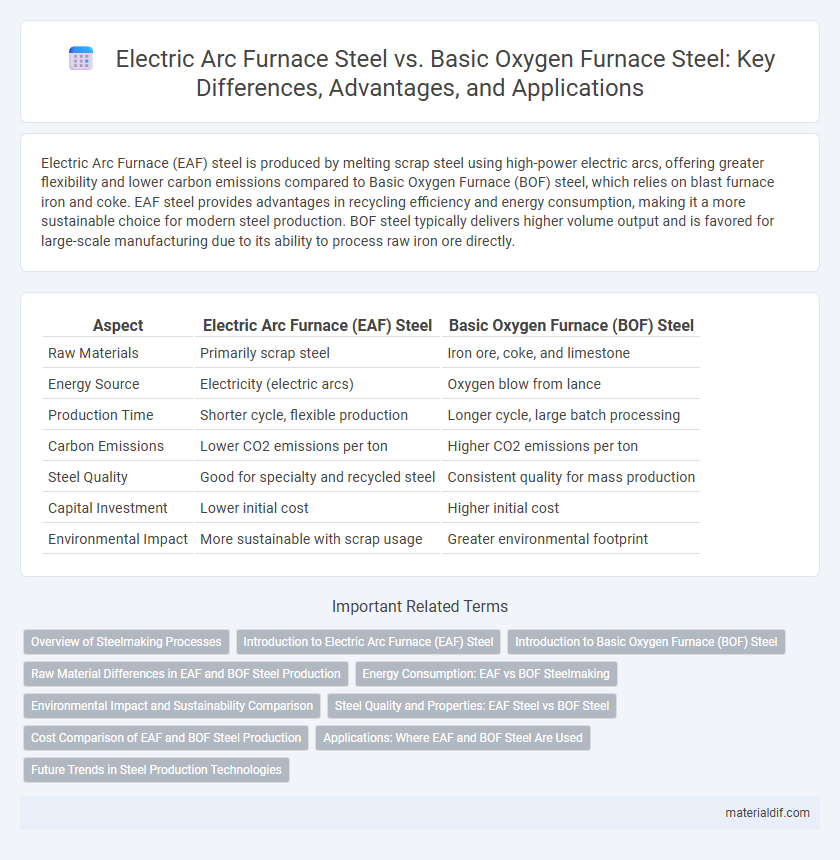

Electric Arc Furnace (EAF) steel is produced by melting scrap steel using high-power electric arcs, offering greater flexibility and lower carbon emissions compared to Basic Oxygen Furnace (BOF) steel, which relies on blast furnace iron and coke. EAF steel provides advantages in recycling efficiency and energy consumption, making it a more sustainable choice for modern steel production. BOF steel typically delivers higher volume output and is favored for large-scale manufacturing due to its ability to process raw iron ore directly.

Table of Comparison

| Aspect | Electric Arc Furnace (EAF) Steel | Basic Oxygen Furnace (BOF) Steel |

|---|---|---|

| Raw Materials | Primarily scrap steel | Iron ore, coke, and limestone |

| Energy Source | Electricity (electric arcs) | Oxygen blow from lance |

| Production Time | Shorter cycle, flexible production | Longer cycle, large batch processing |

| Carbon Emissions | Lower CO2 emissions per ton | Higher CO2 emissions per ton |

| Steel Quality | Good for specialty and recycled steel | Consistent quality for mass production |

| Capital Investment | Lower initial cost | Higher initial cost |

| Environmental Impact | More sustainable with scrap usage | Greater environmental footprint |

Overview of Steelmaking Processes

Electric Arc Furnace (EAF) steelmaking primarily uses electric arcs to melt scrap steel, offering flexibility and energy efficiency with lower carbon emissions compared to Basic Oxygen Furnace (BOF) steelmaking, which relies on blowing oxygen through molten iron to reduce carbon content. EAF processes are favored for recycling steel and producing specialty grades, while BOF is dominant in large-scale, high-volume production from raw iron ore and coke. The key distinction lies in feedstock and energy source, impacting cost, environmental footprint, and production scale.

Introduction to Electric Arc Furnace (EAF) Steel

Electric Arc Furnace (EAF) steel production utilizes electric arcs to melt scrap steel, offering greater energy efficiency and flexibility compared to Basic Oxygen Furnace (BOF) methods. EAF steel is prized for its lower carbon footprint and ability to rapidly adjust production volumes, making it ideal for recycled steel manufacturing. This technology supports sustainable steelmaking by reducing reliance on raw iron ore and enabling superior control over alloy composition.

Introduction to Basic Oxygen Furnace (BOF) Steel

Basic Oxygen Furnace (BOF) steel production involves blowing high-purity oxygen into a molten iron bath to reduce carbon content and impurities, generating high-quality steel with controlled composition. BOF steel is known for its large-scale production efficiency and is primarily sourced from blast furnace pig iron combined with scrap metal. This method enables rapid refining and consistent output, making BOF steel dominant in global steel manufacturing.

Raw Material Differences in EAF and BOF Steel Production

Electric Arc Furnace (EAF) steel production primarily utilizes recycled scrap steel as its raw material, offering flexibility in feedstock sourcing and promoting sustainability through material reuse. In contrast, Basic Oxygen Furnace (BOF) steel relies heavily on iron ore, coke, and fluxes like limestone to produce molten iron before steelmaking, emphasizing the use of primary raw materials. These raw material distinctions significantly influence energy consumption, production cost, and environmental impact in steel manufacturing.

Energy Consumption: EAF vs BOF Steelmaking

Electric Arc Furnace (EAF) steelmaking consumes significantly less energy compared to Basic Oxygen Furnace (BOF) steelmaking, primarily because EAF processes mainly use recycled scrap steel, reducing the need for raw material extraction and processing. EAFs typically require around 400-500 kWh of electricity per ton of steel produced, while BOFs depend heavily on coal and coke, consuming approximately 20-25 GJ of energy per ton due to the energy-intensive conversion of iron ore into steel. This energy efficiency in EAF steelmaking results in lower greenhouse gas emissions and operational costs, making it a more sustainable choice for modern steel production.

Environmental Impact and Sustainability Comparison

Electric Arc Furnace (EAF) steel production significantly reduces environmental impact by utilizing up to 90% scrap steel, resulting in 50-70% lower carbon emissions compared to Basic Oxygen Furnace (BOF) steel, which primarily relies on iron ore and coal. EAF processes consume less energy and generate fewer pollutants, contributing to enhanced sustainability and aligning with circular economy principles. Conversely, BOF steelmaking, while efficient for large-scale production, involves higher fossil fuel consumption and greater greenhouse gas emissions, posing challenges for carbon reduction goals.

Steel Quality and Properties: EAF Steel vs BOF Steel

Electric Arc Furnace (EAF) steel typically exhibits higher scrap content, resulting in greater impurity variations but enhanced flexibility in alloy composition, making it ideal for specialized high-strength and stainless steels. Basic Oxygen Furnace (BOF) steel offers more consistent chemical composition and lower residual elements due to the primary use of molten iron, which ensures superior homogeneity and mechanical properties in large-scale structural applications. EAF steel tends to have better environmental credentials with recycled content, while BOF steel maintains advantages in uniformity and cost-effectiveness for mass production.

Cost Comparison of EAF and BOF Steel Production

Electric Arc Furnace (EAF) steel production generally incurs lower operational costs than Basic Oxygen Furnace (BOF) steel due to reduced raw material requirements and energy efficiency. EAF processes primarily use scrap steel, minimizing the need for expensive iron ore and coke, while BOF relies heavily on these materials, increasing input expenses. The flexibility and lower capital investment of EAF plants further contribute to a cost advantage over BOF in many steel production scenarios.

Applications: Where EAF and BOF Steel Are Used

Electric Arc Furnace (EAF) steel is predominantly used in construction, automotive manufacturing, and infrastructure projects due to its flexibility in recycling scrap metal and producing specialized steel grades. Basic Oxygen Furnace (BOF) steel is commonly applied in large-scale industrial sectors such as shipbuilding, heavy machinery, and pipeline manufacturing, where high volume and consistent steel quality are crucial. EAF steel suits markets demanding sustainability and customization, while BOF steel supports mass production with superior chemical uniformity.

Future Trends in Steel Production Technologies

Electric Arc Furnace (EAF) steel production demonstrates significant growth potential due to its lower carbon emissions and higher flexibility in recycling scrap steel compared to Basic Oxygen Furnace (BOF) steel. Technological advancements in sensor integration, artificial intelligence, and energy-efficient power supplies are driving EAF processes towards enhanced productivity and sustainability. Future trends emphasize decarbonization, circular economy adoption, and digitization, positioning EAF steel as a crucial component in achieving the steel industry's long-term environmental targets.

Electric Arc Furnace Steel vs Basic Oxygen Furnace Steel Infographic

materialdif.com

materialdif.com