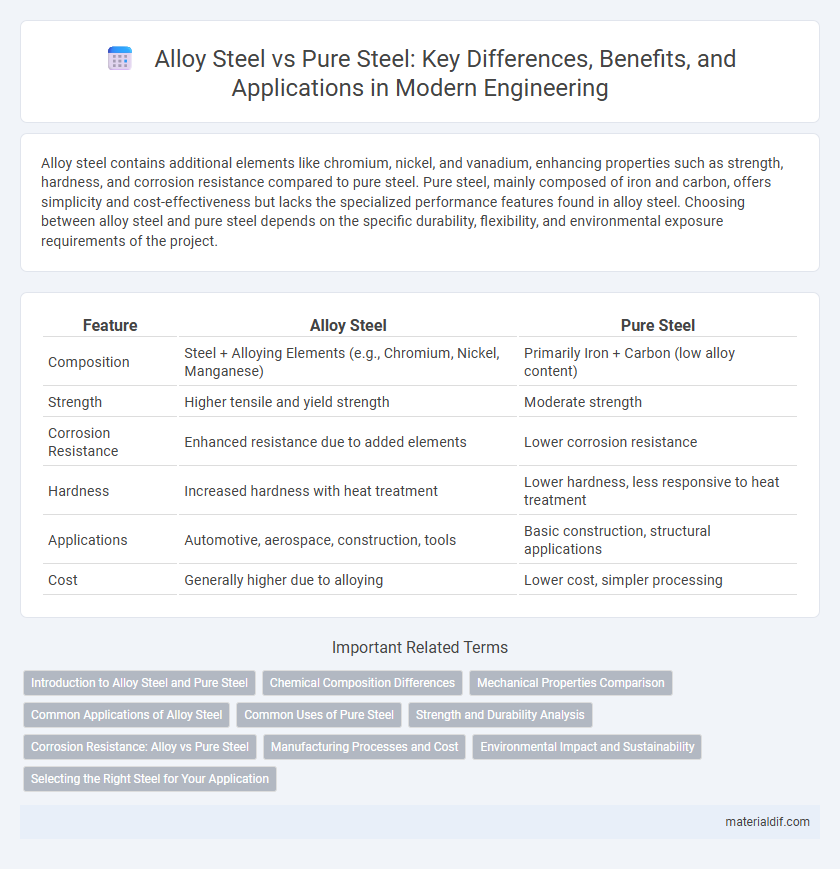

Alloy steel contains additional elements like chromium, nickel, and vanadium, enhancing properties such as strength, hardness, and corrosion resistance compared to pure steel. Pure steel, mainly composed of iron and carbon, offers simplicity and cost-effectiveness but lacks the specialized performance features found in alloy steel. Choosing between alloy steel and pure steel depends on the specific durability, flexibility, and environmental exposure requirements of the project.

Table of Comparison

| Feature | Alloy Steel | Pure Steel |

|---|---|---|

| Composition | Steel + Alloying Elements (e.g., Chromium, Nickel, Manganese) | Primarily Iron + Carbon (low alloy content) |

| Strength | Higher tensile and yield strength | Moderate strength |

| Corrosion Resistance | Enhanced resistance due to added elements | Lower corrosion resistance |

| Hardness | Increased hardness with heat treatment | Lower hardness, less responsive to heat treatment |

| Applications | Automotive, aerospace, construction, tools | Basic construction, structural applications |

| Cost | Generally higher due to alloying | Lower cost, simpler processing |

Introduction to Alloy Steel and Pure Steel

Alloy steel contains various elements such as chromium, nickel, and molybdenum, which enhance its mechanical properties and corrosion resistance compared to pure steel. Pure steel, primarily composed of iron and carbon, offers simplicity and ease of fabrication but lacks the specialized strengths found in alloy variants. The choice between alloy steel and pure steel depends on application requirements like durability, strength, and environmental exposure.

Chemical Composition Differences

Alloy steel contains additional elements such as chromium, nickel, molybdenum, and vanadium, which enhance its mechanical properties and corrosion resistance, whereas pure steel primarily consists of iron with a small percentage of carbon, typically below 2%. The presence of alloying elements in alloy steel alters the microstructure, improving hardness, tensile strength, and toughness compared to pure steel. Chemical composition variations between alloy steel and pure steel significantly influence their applications, with alloy steels preferred for high-strength, wear-resistant, and heat-resistant components.

Mechanical Properties Comparison

Alloy steel exhibits enhanced mechanical properties compared to pure steel, including increased strength, hardness, and wear resistance due to the addition of elements such as chromium, nickel, and molybdenum. Pure steel, primarily composed of iron and carbon, offers good ductility and machinability but lacks the superior tensile strength and corrosion resistance found in alloy variants. The improved mechanical performance of alloy steel makes it ideal for applications requiring durability under high stress and harsh conditions.

Common Applications of Alloy Steel

Alloy steel is widely used in automotive components, construction equipment, and industrial machinery due to its enhanced strength, toughness, and resistance to corrosion and wear. Common applications include gears, shafts, and aircraft parts where high performance under stress is critical. These improvements over pure steel make alloy steel the preferred material in demanding engineering and structural projects.

Common Uses of Pure Steel

Pure steel, composed primarily of iron with minimal carbon content, is extensively used in construction for structural frameworks, offering high ductility and weldability. Its excellent magnetic properties make it ideal for electrical appliances and motor cores. Additionally, pure steel is favored in manufacturing food processing equipment due to its corrosion resistance and ease of cleaning.

Strength and Durability Analysis

Alloy steel exhibits superior strength and durability compared to pure steel due to the inclusion of elements like chromium, nickel, and molybdenum, which enhance hardenability and corrosion resistance. Pure steel, composed mainly of iron and carbon, offers moderate strength but lacks the enhanced mechanical properties and wear resistance found in alloy variations. The tailored chemical composition in alloy steel enables it to withstand extreme stress and environmental conditions, making it ideal for critical structural and industrial applications.

Corrosion Resistance: Alloy vs Pure Steel

Alloy steel exhibits significantly higher corrosion resistance compared to pure steel due to the presence of elements like chromium, nickel, and molybdenum that enhance its ability to withstand rust and oxidation. Pure steel, primarily composed of iron and carbon, is more susceptible to corrosion when exposed to moisture and harsh environments. The enhanced corrosion resistance of alloy steel makes it preferable for applications in marine, chemical, and outdoor environments where durability and longevity are critical.

Manufacturing Processes and Cost

Alloy steel undergoes complex manufacturing processes involving the addition of elements such as chromium, nickel, and molybdenum to enhance properties like strength, hardness, and corrosion resistance, resulting in higher production costs compared to pure steel. Pure steel primarily consists of iron and carbon with minimal alloying elements, enabling simpler manufacturing methods like basic oxygen or electric arc furnace processing, which lowers material and production expenses. Cost efficiency in pure steel manufacturing makes it suitable for large-scale structural applications, while alloy steel's advanced fabrication offers superior performance in specialized industrial environments.

Environmental Impact and Sustainability

Alloy steel, enriched with elements like chromium, nickel, and molybdenum, offers enhanced strength and corrosion resistance, extending the lifespan of steel products and reducing the need for frequent replacements. Pure steel, primarily composed of iron and carbon, has a simpler composition but may require more frequent maintenance and replacement, potentially increasing resource consumption and emissions over time. The environmental impact of alloy steel is often mitigated by its durability, promoting sustainability through longer lifecycle use and improved recyclability compared to pure steel.

Selecting the Right Steel for Your Application

Alloy steel offers enhanced mechanical properties such as increased strength, toughness, and corrosion resistance due to the addition of elements like chromium, nickel, and molybdenum, making it ideal for demanding applications. Pure steel, mainly composed of iron and carbon, provides excellent weldability and machinability, suitable for general construction and manufacturing where extreme performance is not critical. Selecting the right steel depends on the specific requirements of your application, including load-bearing capacity, environmental exposure, and fabrication processes.

Alloy Steel vs Pure Steel Infographic

materialdif.com

materialdif.com