Annealing and normalizing are heat treatment processes used to improve the microstructure and mechanical properties of steel. Annealing involves heating steel to a specific temperature followed by slow cooling to soften the metal, enhance machinability, and relieve internal stresses. Normalizing heats steel above its critical temperature and cools it in air, resulting in a finer grain structure and improved strength and toughness compared to annealed steel.

Table of Comparison

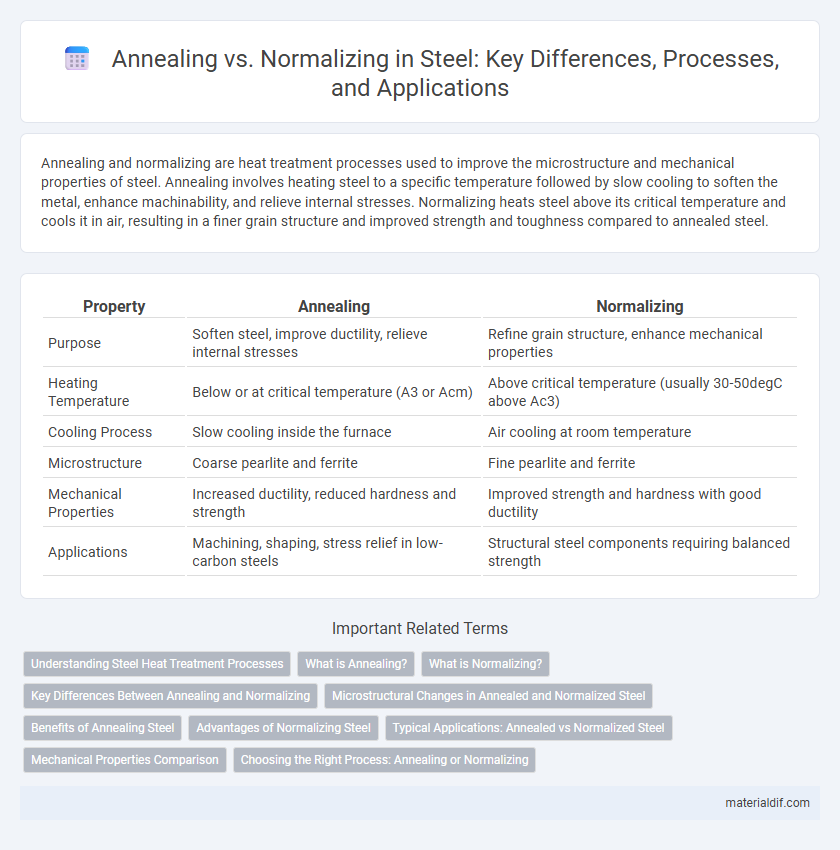

| Property | Annealing | Normalizing |

|---|---|---|

| Purpose | Soften steel, improve ductility, relieve internal stresses | Refine grain structure, enhance mechanical properties |

| Heating Temperature | Below or at critical temperature (A3 or Acm) | Above critical temperature (usually 30-50degC above Ac3) |

| Cooling Process | Slow cooling inside the furnace | Air cooling at room temperature |

| Microstructure | Coarse pearlite and ferrite | Fine pearlite and ferrite |

| Mechanical Properties | Increased ductility, reduced hardness and strength | Improved strength and hardness with good ductility |

| Applications | Machining, shaping, stress relief in low-carbon steels | Structural steel components requiring balanced strength |

Understanding Steel Heat Treatment Processes

Annealing in steel involves heating to a specific temperature followed by slow cooling to refine grain structure and enhance ductility, reducing internal stresses. Normalizing heats steel above its critical temperature and air cools it, resulting in a more uniform and refined grain structure with improved mechanical properties compared to annealed steel. Both processes optimize steel's microstructure but differ in cooling rates, impacting hardness, toughness, and machinability for various industrial applications.

What is Annealing?

Annealing is a heat treatment process used in steel manufacturing where the material is heated to a specific temperature and then cooled slowly to soften the metal, improve ductility, and relieve internal stresses. This controlled cooling refines the grain structure, making the steel easier to machine and enhancing its toughness. Annealed steel typically exhibits reduced hardness compared to normalized steel, making it ideal for subsequent forming or welding operations.

What is Normalizing?

Normalizing is a heat treatment process for steel involving heating the metal to a temperature above its critical range, typically between 800degC and 950degC, followed by air cooling. This process refines the grain structure, relieves internal stresses, and improves mechanical properties such as strength and toughness. Normalizing produces a more uniform microstructure compared to annealing, making the steel harder and stronger.

Key Differences Between Annealing and Normalizing

Annealing involves heating steel to a specific temperature and cooling it slowly to soften the metal, enhance ductility, and relieve internal stresses, whereas normalizing heats steel above its critical point and allows it to cool in air to refine grain structure and improve mechanical properties. Annealed steel exhibits improved machinability and reduced hardness, while normalized steel typically shows greater strength and toughness due to a more uniform microstructure. The choice between annealing and normalizing depends on the desired balance between softness and strength in the final steel product.

Microstructural Changes in Annealed and Normalized Steel

Annealing transforms steel's microstructure by forming coarse pearlite and ferrite, resulting in reduced hardness and enhanced ductility due to slower cooling rates. Normalizing produces a finer pearlite structure with uniform grain size through air cooling, leading to improved strength and toughness compared to annealed steel. These microstructural differences significantly influence mechanical properties, with annealed steel optimized for machinability and normalized steel for structural applications requiring higher strength.

Benefits of Annealing Steel

Annealing steel enhances ductility and reduces hardness, making it easier to machine and form without cracking. This heat treatment process refines the microstructure by relieving internal stresses, which improves toughness and dimensional stability. Annealed steel exhibits improved grain uniformity, leading to consistent mechanical properties ideal for further manufacturing processes.

Advantages of Normalizing Steel

Normalizing steel refines grain structure and enhances mechanical properties by heating above critical temperature and cooling in air, resulting in improved strength and toughness compared to annealing. The process produces a uniform microstructure, which increases wear resistance and dimensional stability in steel components. Normalized steels also exhibit better machinability and prepare the material for subsequent heat treatments more effectively than annealed steels.

Typical Applications: Annealed vs Normalized Steel

Annealed steel is commonly used in applications requiring enhanced ductility and machinability, such as automotive parts, metal forming processes, and electrical components, where softness and ease of shaping are critical. Normalized steel finds typical use in structural applications like bridge construction, pipelines, and heavy machinery parts due to its improved strength, toughness, and uniform grain structure. The choice between annealed and normalized steel depends on the balance needed between malleability and mechanical strength for specific industrial requirements.

Mechanical Properties Comparison

Annealing improves ductility and toughness by producing a coarse pearlitic structure, resulting in lower hardness and tensile strength compared to normalizing. Normalizing refines grain size and produces a more uniform microstructure, enhancing strength and hardness with moderate ductility. Mechanical properties after annealing typically show increased elongation but reduced yield and ultimate tensile strength relative to normalized steel.

Choosing the Right Process: Annealing or Normalizing

Selecting the right heat treatment process depends on the desired mechanical properties and microstructure of steel. Annealing is ideal for achieving maximum ductility and uniform grain structure, typically used for machining or forming operations, while normalizing produces a finer grain size that enhances strength and toughness, making it suitable for structural applications. Understanding the specific requirements of hardness, strength, and machinability helps in choosing between annealing and normalizing for optimal steel performance.

Annealing vs Normalizing Infographic

materialdif.com

materialdif.com