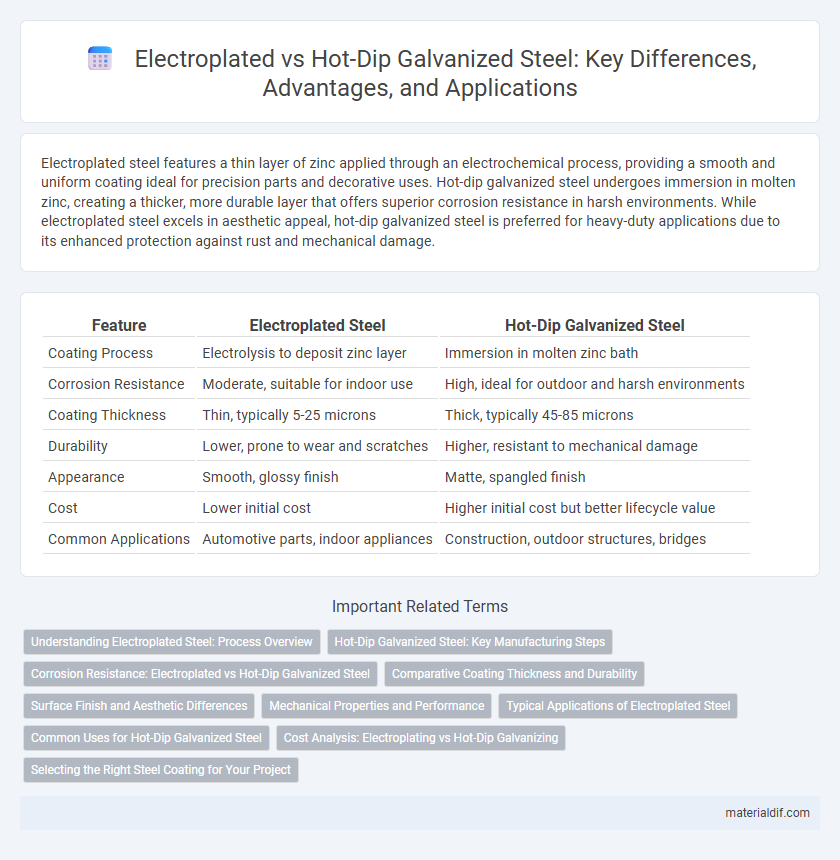

Electroplated steel features a thin layer of zinc applied through an electrochemical process, providing a smooth and uniform coating ideal for precision parts and decorative uses. Hot-dip galvanized steel undergoes immersion in molten zinc, creating a thicker, more durable layer that offers superior corrosion resistance in harsh environments. While electroplated steel excels in aesthetic appeal, hot-dip galvanized steel is preferred for heavy-duty applications due to its enhanced protection against rust and mechanical damage.

Table of Comparison

| Feature | Electroplated Steel | Hot-Dip Galvanized Steel |

|---|---|---|

| Coating Process | Electrolysis to deposit zinc layer | Immersion in molten zinc bath |

| Corrosion Resistance | Moderate, suitable for indoor use | High, ideal for outdoor and harsh environments |

| Coating Thickness | Thin, typically 5-25 microns | Thick, typically 45-85 microns |

| Durability | Lower, prone to wear and scratches | Higher, resistant to mechanical damage |

| Appearance | Smooth, glossy finish | Matte, spangled finish |

| Cost | Lower initial cost | Higher initial cost but better lifecycle value |

| Common Applications | Automotive parts, indoor appliances | Construction, outdoor structures, bridges |

Understanding Electroplated Steel: Process Overview

Electroplated steel undergoes a precise electrochemical process where a thin layer of metal, typically zinc or nickel, is deposited onto the steel surface through an electrolytic bath, enhancing corrosion resistance and surface appearance. This method allows for uniform coating thickness control and produces a smooth, bright finish ideal for decorative and protective applications. The electroplating process operates at lower temperatures compared to hot-dip galvanizing, reducing thermal distortion and substrate damage while enabling intricate surface details to be preserved.

Hot-Dip Galvanized Steel: Key Manufacturing Steps

Hot-dip galvanized steel undergoes a manufacturing process that involves cleaning the steel surface through degreasing and pickling to remove impurities. The steel is then immersed in molten zinc at approximately 450degC, forming a metallurgical bond that provides robust corrosion resistance. This zinc coating offers long-lasting protection against rust, making hot-dip galvanized steel ideal for harsh environments and structural applications.

Corrosion Resistance: Electroplated vs Hot-Dip Galvanized Steel

Electroplated steel offers a thin, uniform zinc coating that provides moderate corrosion resistance suitable for indoor applications, but its protection diminishes rapidly in harsh environments. Hot-dip galvanized steel features a thicker, robust zinc layer formed by dipping the steel into molten zinc, delivering superior corrosion resistance and durability in outdoor and marine settings. The metallurgical bond in hot-dip galvanizing prevents rust formation more effectively than the electroplated coating, making it ideal for long-term protection against corrosion.

Comparative Coating Thickness and Durability

Electroplated steel features a thin, uniform zinc coating typically ranging from 5 to 25 microns, providing moderate corrosion resistance primarily for indoor applications. Hot-dip galvanized steel, by contrast, offers a significantly thicker coating--often between 45 to 100 microns--resulting in superior durability and long-lasting protection against harsh outdoor environments. The increased coating thickness of hot-dip galvanization enhances resistance to abrasion and environmental damage, making it preferable for structural and industrial uses requiring extended service life.

Surface Finish and Aesthetic Differences

Electroplated steel provides a uniform, smooth surface finish with a bright, shiny appearance ideal for decorative applications, while hot-dip galvanized steel features a thicker zinc coating with a rougher, matte, spangled texture that enhances corrosion resistance. The electroplating process offers precise control over coating thickness, resulting in consistent aesthetic quality, whereas hot-dip galvanizing forms a metallurgical bond with the steel, creating a rugged surface finish that changes over time due to weathering. For projects prioritizing visual appeal, electroplated steel delivers superior luster and polish, contrasting with the more durable, industrial look of hot-dip galvanized steel.

Mechanical Properties and Performance

Electroplated steel features a thin, uniform coating of zinc that improves surface smoothness and dimensional accuracy but offers limited corrosion resistance and reduced impact toughness compared to hot-dip galvanized steel. Hot-dip galvanized steel exhibits a thicker zinc coating, enhancing corrosion protection, mechanical strength, and durability under harsh environmental conditions with superior resistance to abrasion and mechanical stress. Performance-wise, hot-dip galvanizing provides longer-lasting protection in outdoor and industrial applications, while electroplated steel is better suited for precision components requiring fine surface finishes.

Typical Applications of Electroplated Steel

Electroplated steel is commonly used in automotive components, electronic housings, and decorative hardware due to its smooth, uniform coating that enhances aesthetic appeal and corrosion resistance. Its precise, thin metal layers make it ideal for applications requiring tight tolerances and excellent conductivity, such as connectors and circuit boards. Unlike hot-dip galvanized steel, electroplated steel offers superior surface finish quality, making it suitable for visible consumer products.

Common Uses for Hot-Dip Galvanized Steel

Hot-dip galvanized steel is widely used in construction for structural beams, outdoor fencing, and roofing due to its superior corrosion resistance and long-lasting protection against harsh weather conditions. It is also commonly applied in automotive manufacturing for chassis components and exhaust systems where durability and rust prevention are critical. Additionally, hot-dip galvanizing is favored in utility poles, electrical towers, and agricultural equipment, providing a robust coating that extends the steel's service life in demanding environments.

Cost Analysis: Electroplating vs Hot-Dip Galvanizing

Electroplated steel typically incurs higher initial costs due to its precision-controlled thin coating, making it suitable for applications requiring fine aesthetic finishes and corrosion resistance. Hot-dip galvanized steel offers a thicker, more durable zinc layer at a lower cost, providing long-term corrosion protection and reduced maintenance expenses. Evaluating total lifecycle cost reveals hot-dip galvanizing as more cost-effective for structural steel exposed to harsh environments.

Selecting the Right Steel Coating for Your Project

Electroplated steel offers a thin, uniform coating ideal for decorative purposes and light corrosion resistance, making it suitable for indoor applications and precision parts. Hot-dip galvanized steel provides a thicker, more durable zinc layer that withstands harsh outdoor environments and heavy wear, preferred for construction, automotive, and infrastructure projects. Selecting the right coating depends on environmental exposure, required corrosion resistance, and budget constraints, with hot-dip galvanizing favored for longevity and electroplating chosen for aesthetic finish.

Electroplated Steel vs Hot-Dip Galvanized Steel Infographic

materialdif.com

materialdif.com