Prepainted steel offers enhanced corrosion resistance and aesthetic appeal compared to bare steel, making it ideal for applications requiring durability and visual quality. It reduces the need for additional finishing processes, saving time and cost in manufacturing. Bare steel, while more economical upfront, requires protective coatings or treatments to prevent rust and degradation over time.

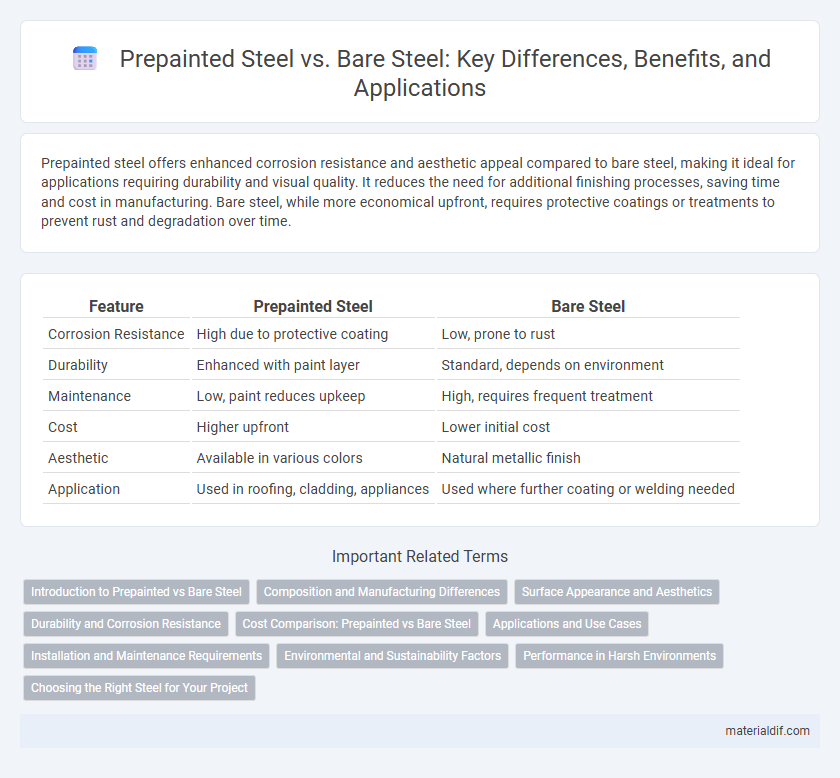

Table of Comparison

| Feature | Prepainted Steel | Bare Steel |

|---|---|---|

| Corrosion Resistance | High due to protective coating | Low, prone to rust |

| Durability | Enhanced with paint layer | Standard, depends on environment |

| Maintenance | Low, paint reduces upkeep | High, requires frequent treatment |

| Cost | Higher upfront | Lower initial cost |

| Aesthetic | Available in various colors | Natural metallic finish |

| Application | Used in roofing, cladding, appliances | Used where further coating or welding needed |

Introduction to Prepainted vs Bare Steel

Prepainted steel features a protective coating of paint applied during manufacturing, enhancing corrosion resistance and aesthetic appeal compared to bare steel, which lacks any surface treatment. This coating not only extends the lifespan of steel but also reduces maintenance costs, making prepainted steel ideal for construction, automotive, and appliance industries. Bare steel, while offering high strength and versatility, requires additional finishing processes to prevent rust and degradation in harsh environments.

Composition and Manufacturing Differences

Prepainted steel features a zinc- or aluminum-zinc alloy-coated base layer topped with a polymer-based paint, enhancing corrosion resistance and aesthetics. Bare steel is typically composed of untreated carbon steel or low-alloy steel without protective coatings, making it more prone to rust and surface degradation. Manufacturing for prepainted steel involves continuous coil coating processes, including cleaning, surface treatment, and curing, whereas bare steel undergoes standard rolling and annealing without additional surface finishing.

Surface Appearance and Aesthetics

Prepainted steel offers superior surface appearance and aesthetics due to its uniform color, smooth finish, and resistance to fading or chipping, making it ideal for architectural and decorative applications. Bare steel, while providing a natural metallic look, is prone to oxidation and surface imperfections that can diminish its visual appeal over time. The choice between prepainted and bare steel significantly impacts the longevity and maintenance of the product's aesthetic quality.

Durability and Corrosion Resistance

Prepainted steel offers superior corrosion resistance compared to bare steel due to its protective coating, which acts as a barrier against moisture and environmental contaminants. The durability of prepainted steel extends the lifespan of structures by preventing rust and degradation, reducing maintenance costs significantly. In contrast, bare steel is more susceptible to oxidation and requires frequent treatments to maintain its integrity in harsh conditions.

Cost Comparison: Prepainted vs Bare Steel

Prepainted steel typically incurs higher initial costs due to coating and processing expenses compared to bare steel, which is generally cheaper upfront. However, prepainted steel offers long-term savings by reducing maintenance, corrosion protection, and repainting costs. When evaluating total lifecycle expenses, prepainted steel can be more cost-effective despite the higher initial investment.

Applications and Use Cases

Prepainted steel offers enhanced corrosion resistance and aesthetic appeal, making it ideal for applications in construction, automotive panels, and appliances where durability and visual quality are critical. Bare steel is preferred for environments requiring subsequent coating or welding, commonly used in structural frameworks, heavy machinery, and metal fabrication industries. The choice between prepainted and bare steel depends on specific performance requirements, exposure conditions, and manufacturing processes.

Installation and Maintenance Requirements

Prepainted steel offers significant advantages over bare steel regarding installation and maintenance requirements, as its protective coating reduces the need for additional surface treatments and minimizes corrosion risks. The pre-applied paint enhances durability, allowing for quicker installation times and lower long-term maintenance costs compared to bare steel, which requires frequent painting or galvanizing after installation. This durability optimizes project timelines and reduces overall lifecycle expenses in construction and manufacturing applications.

Environmental and Sustainability Factors

Prepainted steel reduces environmental impact by extending product lifespan and minimizing maintenance through corrosion-resistant coatings, which decrease the need for frequent replacements and reduce landfill waste. In contrast, bare steel is prone to rust and degradation, leading to higher resource consumption for repairs and replacements, increasing the overall carbon footprint. Sustainable manufacturing of prepainted steel often incorporates eco-friendly paints and processes that emit fewer volatile organic compounds (VOCs), supporting greener construction and manufacturing industries.

Performance in Harsh Environments

Prepainted steel offers superior corrosion resistance and durability in harsh environments compared to bare steel, due to its protective coating that shields against moisture, UV rays, and chemical exposure. Bare steel, prone to rust and degradation when unprotected, requires additional treatments or maintenance to withstand extreme weather conditions. The enhanced performance of prepainted steel makes it ideal for applications in coastal areas, industrial settings, and infrastructure exposed to aggressive environmental factors.

Choosing the Right Steel for Your Project

Prepainted steel offers enhanced corrosion resistance and aesthetic versatility, making it ideal for architectural and decorative projects requiring durability and color retention. Bare steel provides greater flexibility for custom finishes and welding applications, suitable for structural components where surface coating will be applied later. Selecting the right steel depends on project requirements such as environmental exposure, desired appearance, and fabrication methods.

Prepainted Steel vs Bare Steel Infographic

materialdif.com

materialdif.com