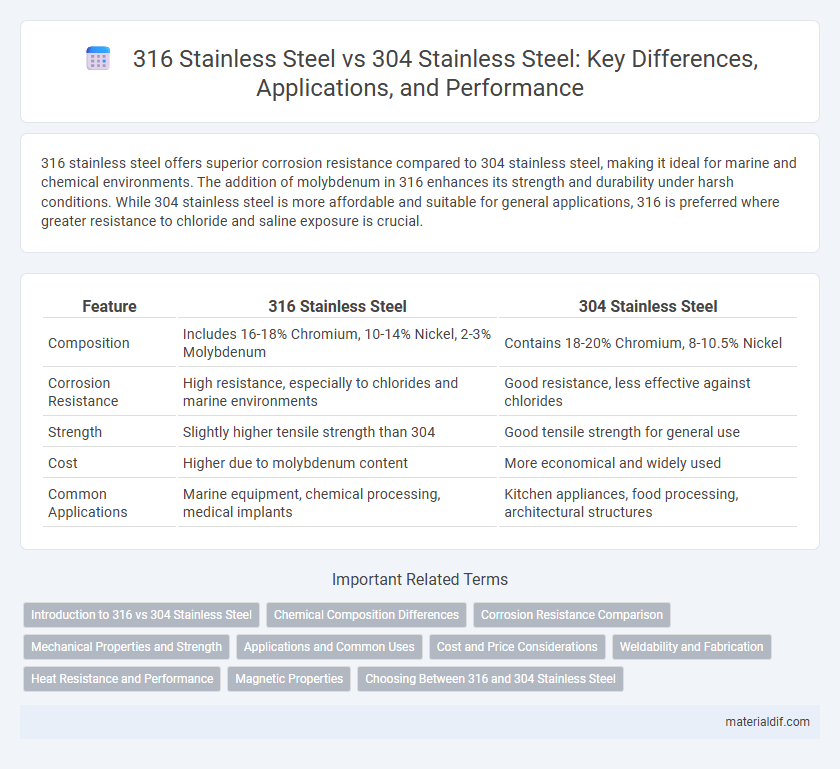

316 stainless steel offers superior corrosion resistance compared to 304 stainless steel, making it ideal for marine and chemical environments. The addition of molybdenum in 316 enhances its strength and durability under harsh conditions. While 304 stainless steel is more affordable and suitable for general applications, 316 is preferred where greater resistance to chloride and saline exposure is crucial.

Table of Comparison

| Feature | 316 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Composition | Includes 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum | Contains 18-20% Chromium, 8-10.5% Nickel |

| Corrosion Resistance | High resistance, especially to chlorides and marine environments | Good resistance, less effective against chlorides |

| Strength | Slightly higher tensile strength than 304 | Good tensile strength for general use |

| Cost | Higher due to molybdenum content | More economical and widely used |

| Common Applications | Marine equipment, chemical processing, medical implants | Kitchen appliances, food processing, architectural structures |

Introduction to 316 vs 304 Stainless Steel

316 stainless steel contains molybdenum, enhancing corrosion resistance especially against chlorides and marine environments, making it ideal for chemical processing and marine applications. In contrast, 304 stainless steel is more common and cost-effective, offering excellent strength and oxidation resistance but less protection against pitting and crevice corrosion. Both alloys are austenitic stainless steels widely used for their durability and versatility in various industrial and household applications.

Chemical Composition Differences

316 stainless steel contains molybdenum, typically 2-3%, which enhances corrosion resistance, especially against chlorides and industrial solvents, a feature absent in 304 stainless steel. Both alloys primarily consist of iron, chromium (about 18-20%), and nickel (8-12%), but 304 lacks the added molybdenum that makes 316 more suitable for harsh environments. The carbon content is low in both types, usually under 0.08%, minimizing carbide precipitation and improving weldability.

Corrosion Resistance Comparison

316 stainless steel offers superior corrosion resistance compared to 304 stainless steel due to its higher molybdenum content, which enhances resistance to chlorides and marine environments. 304 stainless steel, while corrosion-resistant in many settings, is more susceptible to pitting and crevice corrosion when exposed to saltwater or chloride-rich environments. This makes 316 stainless steel the preferred choice for applications requiring enhanced durability in harsh corrosive conditions.

Mechanical Properties and Strength

316 stainless steel exhibits higher tensile strength and superior corrosion resistance than 304 stainless steel due to its molybdenum content, enhancing durability in harsh environments. Both alloys have similar yield strength around 290 MPa, but 316 offers better creep resistance and toughness at elevated temperatures. This makes 316 ideal for marine applications and chemical processing, while 304 is preferred for general use with slightly lower mechanical demands.

Applications and Common Uses

316 stainless steel is widely used in marine environments, medical instruments, and chemical processing due to its superior corrosion resistance and nickel-molybdenum content. 304 stainless steel is commonly found in kitchen equipment, food processing, and architectural applications for its excellent formability and ease of cleaning. Both grades serve in industrial settings, but 316 is preferred where exposure to chloride or harsh chemicals is frequent.

Cost and Price Considerations

316 stainless steel generally costs 20-30% more than 304 stainless steel due to its higher nickel and molybdenum content, which enhances corrosion resistance. The price difference is justified in applications exposed to harsh environments, such as marine or chemical processing, where 316's durability reduces maintenance expenses. For budget-sensitive projects with less corrosive conditions, 304 stainless steel offers a cost-effective alternative with adequate strength and corrosion resistance.

Weldability and Fabrication

316 stainless steel offers superior corrosion resistance compared to 304 stainless steel, making it ideal for welding applications exposed to harsh environments. Both grades exhibit good weldability with minimal risk of cracking, but 316 requires slightly more careful heat control to maintain its corrosion-resistant properties during fabrication. Fabrication of 304 stainless steel is generally easier due to its lower nickel and molybdenum content, promoting better machinability and formability in standard industrial processes.

Heat Resistance and Performance

316 stainless steel offers superior heat resistance compared to 304 stainless steel, maintaining strength and corrosion resistance at temperatures up to 870degC (1600degF). In contrast, 304 stainless steel is typically effective up to around 925degC (1700degF) but starts to lose mechanical properties earlier under prolonged heat exposure. The enhanced molybdenum content in 316 steel improves its performance in high-temperature and corrosive environments, making it ideal for applications like marine and chemical processing industries.

Magnetic Properties

316 stainless steel exhibits lower magnetic permeability compared to 304 stainless steel, making it less likely to become magnetized in typical applications. The higher nickel and molybdenum content in 316 enhances its austenitic structure, which contributes to its non-magnetic characteristics. While 304 stainless steel can show slight magnetism after cold working, 316 generally remains non-magnetic even under similar conditions.

Choosing Between 316 and 304 Stainless Steel

316 stainless steel contains molybdenum, providing superior corrosion resistance against chloride environments compared to 304 stainless steel, making it ideal for marine and chemical applications. 304 stainless steel offers excellent durability and resistance to oxidation in less aggressive environments, often making it the cost-effective choice for general-purpose use. Selecting between 316 and 304 stainless steel depends on the specific exposure conditions, budget considerations, and the required longevity of the material in service.

316 Stainless Steel vs 304 Stainless Steel Infographic

materialdif.com

materialdif.com