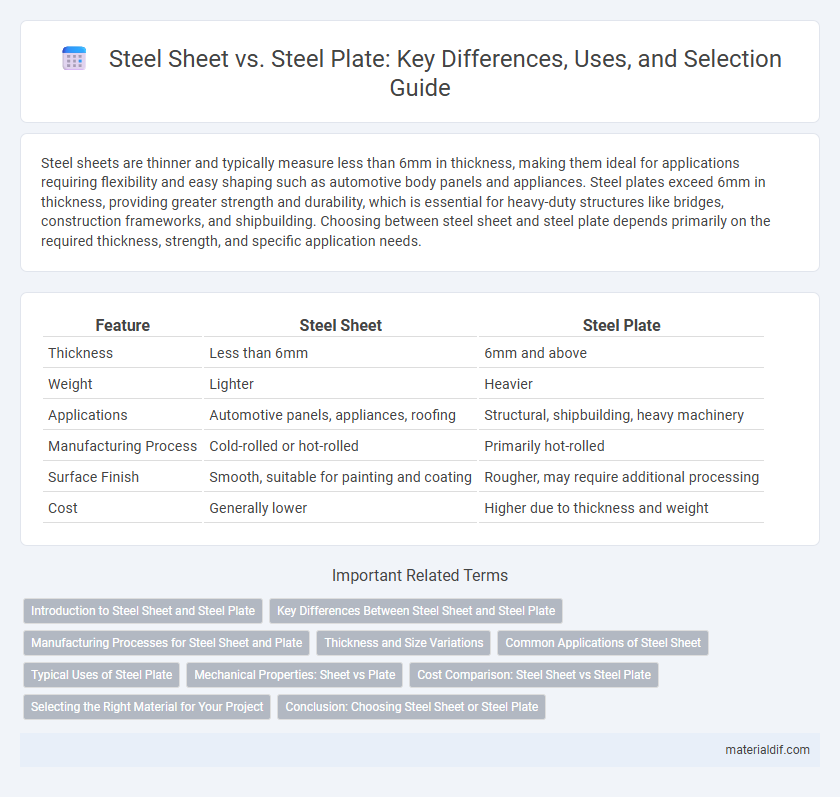

Steel sheets are thinner and typically measure less than 6mm in thickness, making them ideal for applications requiring flexibility and easy shaping such as automotive body panels and appliances. Steel plates exceed 6mm in thickness, providing greater strength and durability, which is essential for heavy-duty structures like bridges, construction frameworks, and shipbuilding. Choosing between steel sheet and steel plate depends primarily on the required thickness, strength, and specific application needs.

Table of Comparison

| Feature | Steel Sheet | Steel Plate |

|---|---|---|

| Thickness | Less than 6mm | 6mm and above |

| Weight | Lighter | Heavier |

| Applications | Automotive panels, appliances, roofing | Structural, shipbuilding, heavy machinery |

| Manufacturing Process | Cold-rolled or hot-rolled | Primarily hot-rolled |

| Surface Finish | Smooth, suitable for painting and coating | Rougher, may require additional processing |

| Cost | Generally lower | Higher due to thickness and weight |

Introduction to Steel Sheet and Steel Plate

Steel sheets and steel plates are fundamental flat-rolled steel products used in construction, automotive, and manufacturing industries. Steel sheets are typically thinner, ranging from 0.5 mm to 6 mm, and offer flexibility for applications like roofing, automotive body panels, and appliances. Steel plates, thicker than 6 mm, provide superior strength and durability for heavy-duty uses such as shipbuilding, structural components, and industrial machinery.

Key Differences Between Steel Sheet and Steel Plate

Steel sheets and steel plates differ primarily in thickness, with sheets typically measuring less than 6mm and plates exceeding this threshold, impacting their strength and application. Steel sheets offer greater flexibility and are commonly used in automotive bodies and roofing, while steel plates provide enhanced durability suited for heavy-duty construction and shipbuilding. Surface finish and manufacturing processes also diverge, where sheets undergo rolling to ensure uniformity, contrasting with the more robust forging used for plates.

Manufacturing Processes for Steel Sheet and Plate

Steel sheets are typically produced through cold rolling or hot rolling processes that reduce the thickness of steel coils to precise measurements, ensuring uniform surface finish and flexibility for applications like automotive panels and appliances. Steel plates undergo heavy rolling and controlled cooling, often produced in thicker gauges, making them suitable for structural applications such as shipbuilding, bridges, and heavy machinery. The manufacturing process differences impact mechanical properties, with sheets offering higher ductility and plates providing enhanced strength and toughness for demanding uses.

Thickness and Size Variations

Steel sheets typically measure less than 6 mm in thickness, offering greater flexibility and ease of fabrication, while steel plates are thicker, often exceeding 6 mm, providing enhanced strength and durability for heavy-duty applications. The size variations in steel sheets allow for diverse applications in automotive and construction industries, whereas steel plates, due to their larger dimensions, are favored in shipbuilding and structural engineering. Thickness and size distinctions directly influence the mechanical properties, processing methods, and end-use performance of both steel sheets and plates.

Common Applications of Steel Sheet

Steel sheets are widely used in automotive body panels, appliances, and roofing materials due to their thin, flexible properties allowing easy shaping and welding. In construction, steel sheets serve as cladding, ductwork, and structural support elements, benefiting from their corrosion resistance when coated. Their precision and smooth surface finish make them ideal for manufacturing electronic enclosures and industrial equipment.

Typical Uses of Steel Plate

Steel plate is primarily used in heavy-duty applications such as shipbuilding, bridges, construction, industrial machinery, and military armor due to its thickness and strength. It offers superior load-bearing capabilities compared to steel sheet, making it ideal for structural components and pressure vessels. Common industries utilizing steel plate include oil and gas, transportation, and manufacturing where durability and toughness are critical.

Mechanical Properties: Sheet vs Plate

Steel sheets typically have thinner gauges ranging from 0.5mm to 6mm, resulting in higher flexibility and better formability compared to steel plates, which are thicker than 6mm and provide greater strength and durability. Mechanical properties such as tensile strength and yield strength tend to be higher in steel plates due to their increased thickness, making them suitable for heavy structural applications requiring load-bearing capacity. Steel sheets excel in applications requiring precise bending and shaping, while steel plates are preferred where impact resistance and structural integrity under stress are critical.

Cost Comparison: Steel Sheet vs Steel Plate

Steel sheets typically cost less than steel plates due to their thinner gauge and easier manufacturing process, making them more economical for projects requiring lighter materials. Steel plates, being thicker and heavier, incur higher production and transportation costs, resulting in a greater price per unit. When choosing between the two, budget considerations favor steel sheets for cost-efficiency, while steel plates justify their expense through enhanced strength and durability for heavy-duty applications.

Selecting the Right Material for Your Project

Steel sheets, typically thinner than 6mm, are ideal for applications requiring flexibility and lightweight properties, such as automotive panels and roofing. Steel plates, thicker than 6mm, provide enhanced strength and durability, making them suitable for heavy-duty construction, shipbuilding, and industrial machinery. Choosing between steel sheet and plate depends on the specific project requirements regarding thickness, strength, and end-use environment.

Conclusion: Choosing Steel Sheet or Steel Plate

Steel sheets offer thinner, more flexible options ideal for automotive, appliance, and construction applications requiring easy shaping and welding. Steel plates provide thicker, stronger materials suitable for heavy-duty structural projects, shipbuilding, and industrial equipment that demand high strength and durability. Selecting between steel sheet and steel plate depends on project requirements for thickness, strength, and formability to ensure optimal performance and cost efficiency.

Steel Sheet vs Steel Plate Infographic

materialdif.com

materialdif.com