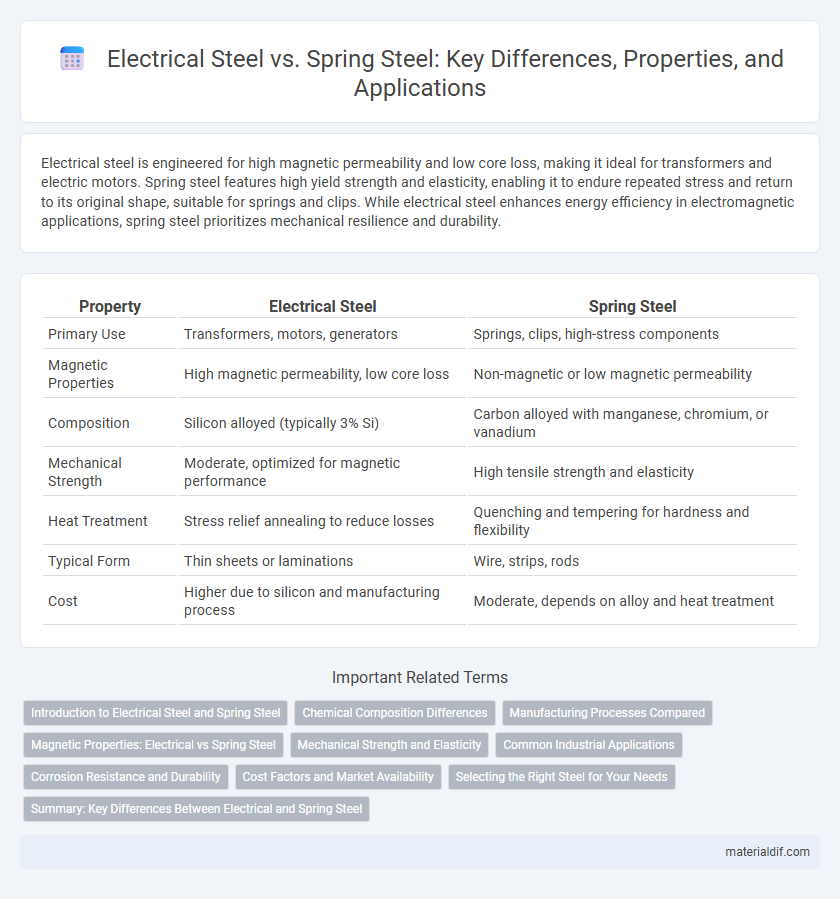

Electrical steel is engineered for high magnetic permeability and low core loss, making it ideal for transformers and electric motors. Spring steel features high yield strength and elasticity, enabling it to endure repeated stress and return to its original shape, suitable for springs and clips. While electrical steel enhances energy efficiency in electromagnetic applications, spring steel prioritizes mechanical resilience and durability.

Table of Comparison

| Property | Electrical Steel | Spring Steel |

|---|---|---|

| Primary Use | Transformers, motors, generators | Springs, clips, high-stress components |

| Magnetic Properties | High magnetic permeability, low core loss | Non-magnetic or low magnetic permeability |

| Composition | Silicon alloyed (typically 3% Si) | Carbon alloyed with manganese, chromium, or vanadium |

| Mechanical Strength | Moderate, optimized for magnetic performance | High tensile strength and elasticity |

| Heat Treatment | Stress relief annealing to reduce losses | Quenching and tempering for hardness and flexibility |

| Typical Form | Thin sheets or laminations | Wire, strips, rods |

| Cost | Higher due to silicon and manufacturing process | Moderate, depends on alloy and heat treatment |

Introduction to Electrical Steel and Spring Steel

Electrical steel, also known as silicon steel, is a specialized alloy designed primarily for magnetic applications such as transformers, motors, and generators due to its high electrical resistivity and low hysteresis loss. Spring steel is a high-carbon or alloy steel known for its exceptional yield strength and elasticity, making it ideal for manufacturing springs, clips, and other components requiring high fatigue resistance. Both steels serve distinct industrial purposes, with electrical steel emphasizing magnetic performance and spring steel focusing on mechanical resilience.

Chemical Composition Differences

Electrical steel typically contains higher silicon content, around 1-3.5%, which enhances its magnetic permeability and reduces core losses in electromagnetic applications. Spring steel, on the other hand, has increased carbon content, generally between 0.5-1.0%, providing greater tensile strength and elasticity for mechanical uses. The distinct chemical compositions tailor electrical steel for efficient magnetic performance, while spring steel achieves superior mechanical resilience.

Manufacturing Processes Compared

Electrical steel is produced through a specialized cold rolling process followed by annealing to enhance its magnetic properties, while spring steel undergoes heat treatment involving quenching and tempering to achieve high tensile strength and elasticity. Grain-oriented electrical steel requires precise control of crystal orientation during manufacturing, contrasting with the more conventional deformation and thermal cycles used in spring steel production. The manufacturing process differences directly influence the performance characteristics, with electrical steel optimized for magnetic applications and spring steel tailored for mechanical resilience.

Magnetic Properties: Electrical vs Spring Steel

Electrical steel exhibits superior magnetic properties, including low core loss and high magnetic permeability, making it essential for transformers and electric motors. Spring steel, however, lacks significant magnetic characteristics and is primarily engineered for high tensile strength and elasticity in mechanical applications. The distinct magnetic performance of electrical steel optimizes energy efficiency in electromagnetic devices, unlike spring steel which is designed for mechanical resilience.

Mechanical Strength and Elasticity

Electrical steel exhibits high magnetic permeability and moderate mechanical strength, optimized for minimizing core losses in transformers and motors, while spring steel offers superior mechanical strength and exceptional elasticity essential for applications requiring high fatigue resistance and energy storage. The elasticity of spring steel allows it to endure repetitive stress without permanent deformation, contrasting with electrical steel, which prioritizes magnetic performance over mechanical resilience. These distinct properties make electrical steel ideal for electromagnetic applications and spring steel suited for mechanical components like springs and clips.

Common Industrial Applications

Electrical steel is primarily used in transformers, electric motors, and generators due to its high magnetic permeability and low core loss, enhancing energy efficiency and performance. Spring steel, valued for its high yield strength and elasticity, finds extensive applications in automotive suspension systems, industrial machinery springs, and various load-bearing components. Both steels serve critical roles in industrial sectors where specific mechanical or electromagnetic properties are essential for operational reliability and durability.

Corrosion Resistance and Durability

Electrical steel exhibits superior corrosion resistance due to its silicon content and specialized insulation coating, making it ideal for applications exposed to moisture and oxidation. Spring steel, known for its high tensile strength and excellent fatigue resistance, offers exceptional durability in mechanical and dynamic stress environments but lacks significant corrosion resistance without additional treatment. The choice between the two steels depends on the requirement for either enhanced electrical performance and corrosion protection or mechanical strength and resilience under repeated deformation.

Cost Factors and Market Availability

Electrical steel typically incurs higher costs due to its specialized alloy composition and processing techniques designed to enhance magnetic properties, making it essential in transformers and electric motors. Spring steel, with its simpler carbon-based composition and widespread production, tends to be more cost-effective and readily available for applications in automotive and machinery springs. Market availability of electrical steel is more limited and region-specific, often influenced by demand in the electronics industry, whereas spring steel enjoys broader global distribution because of its versatile usage across various manufacturing sectors.

Selecting the Right Steel for Your Needs

Electrical steel offers high magnetic permeability and low core loss, making it ideal for transformers, motors, and generators where efficient electromagnetic performance is critical. Spring steel is characterized by its excellent elasticity, tensile strength, and fatigue resistance, suited for manufacturing springs, clips, and automotive components requiring flexibility and durability. Selecting the right steel depends on whether your application demands magnetic properties for electrical efficiency or mechanical resilience for load-bearing and repetitive motion.

Summary: Key Differences Between Electrical and Spring Steel

Electrical steel is primarily engineered for its magnetic properties, featuring low core loss and high permeability, making it ideal for transformers, motors, and generators. Spring steel, on the other hand, is characterized by high yield strength and excellent elasticity, designed to withstand mechanical stress and return to its original shape, commonly used in springs and high-stress components. The key differences lie in their composition and applications: electrical steel emphasizes magnetic efficiency, while spring steel prioritizes mechanical resilience.

Electrical Steel vs Spring Steel Infographic

materialdif.com

materialdif.com