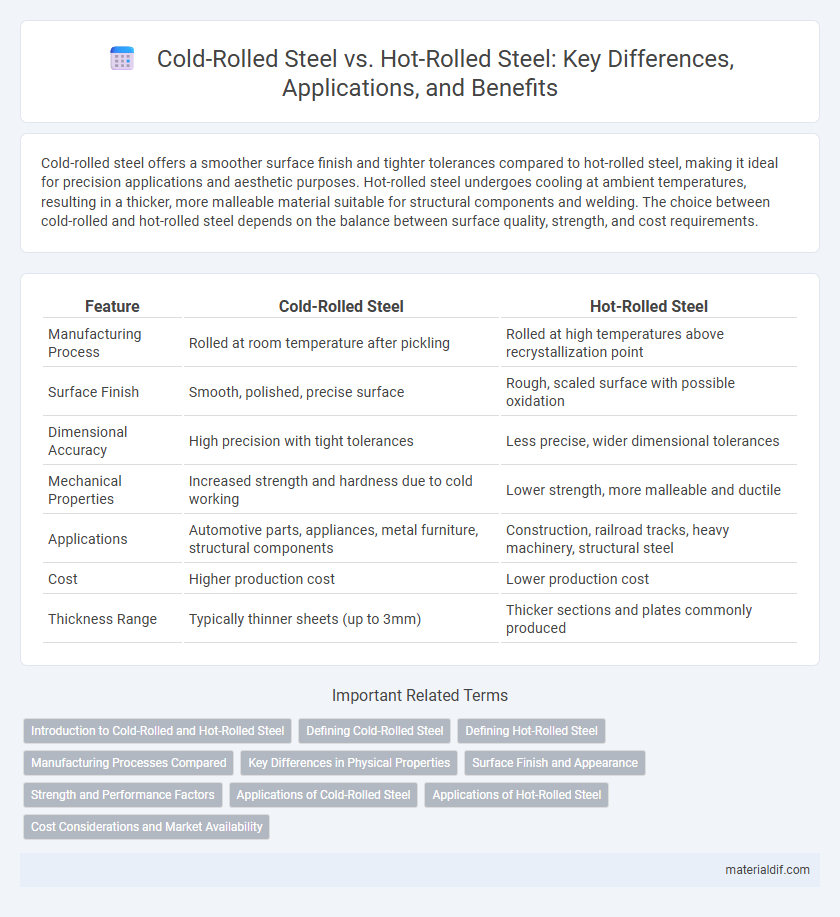

Cold-rolled steel offers a smoother surface finish and tighter tolerances compared to hot-rolled steel, making it ideal for precision applications and aesthetic purposes. Hot-rolled steel undergoes cooling at ambient temperatures, resulting in a thicker, more malleable material suitable for structural components and welding. The choice between cold-rolled and hot-rolled steel depends on the balance between surface quality, strength, and cost requirements.

Table of Comparison

| Feature | Cold-Rolled Steel | Hot-Rolled Steel |

|---|---|---|

| Manufacturing Process | Rolled at room temperature after pickling | Rolled at high temperatures above recrystallization point |

| Surface Finish | Smooth, polished, precise surface | Rough, scaled surface with possible oxidation |

| Dimensional Accuracy | High precision with tight tolerances | Less precise, wider dimensional tolerances |

| Mechanical Properties | Increased strength and hardness due to cold working | Lower strength, more malleable and ductile |

| Applications | Automotive parts, appliances, metal furniture, structural components | Construction, railroad tracks, heavy machinery, structural steel |

| Cost | Higher production cost | Lower production cost |

| Thickness Range | Typically thinner sheets (up to 3mm) | Thicker sections and plates commonly produced |

Introduction to Cold-Rolled and Hot-Rolled Steel

Cold-rolled steel is produced by rolling steel at room temperature, enhancing surface finish, dimensional accuracy, and strength through strain hardening. Hot-rolled steel undergoes processing at temperatures above the recrystallization point, allowing easier shaping but resulting in a rougher surface and less precise dimensions. These fundamental differences influence their applications, with cold-rolled steel preferred for precision and aesthetics, while hot-rolled steel suits structural uses.

Defining Cold-Rolled Steel

Cold-rolled steel is a type of steel processed at room temperature, resulting in a smoother surface finish and tighter tolerances compared to hot-rolled steel. This method involves passing the steel through rollers below its recrystallization temperature, enhancing strength and hardness through strain hardening. Cold-rolled steel is commonly used in applications requiring precision and aesthetic appeal, such as automotive panels and appliances.

Defining Hot-Rolled Steel

Hot-rolled steel is produced by rolling the steel at high temperatures above its recrystallization point, typically over 1700degF (926degC), which allows shaping and forming with reduced strength but enhanced ductility. This process results in a more malleable steel with a rougher surface finish and looser dimensional tolerances compared to cold-rolled steel. Hot-rolled steel is commonly used in construction, automotive frames, and heavy equipment where precise dimensions are less critical than strength and formability.

Manufacturing Processes Compared

Cold-rolled steel is manufactured by further processing hot-rolled steel through rolling at room temperature, enhancing surface finish and dimensional accuracy. Hot-rolled steel is produced by rolling steel slabs at temperatures above 1,700degF, allowing easier shaping but resulting in a rougher surface and less precise dimensions. The cold-rolling process increases strength and hardness through strain hardening, whereas hot-rolled steel retains more ductility due to the recrystallization that occurs at high temperatures.

Key Differences in Physical Properties

Cold-rolled steel exhibits a smoother surface finish and higher tensile strength due to being processed at room temperature, which enhances its dimensional accuracy and hardness. Hot-rolled steel, processed at high temperatures above 1700degF, demonstrates greater ductility and improved machinability but has a rougher surface and more variable thickness. The choice between cold-rolled and hot-rolled steel depends on specific application requirements such as precision, strength, and flexibility.

Surface Finish and Appearance

Cold-rolled steel features a smooth, refined surface finish due to its processing at room temperature, resulting in a more aesthetically pleasing and consistent appearance ideal for visible applications. Hot-rolled steel exhibits a rougher, scaled surface with a duller, matte finish caused by cooling at high temperatures, often requiring further finishing for decorative use. The superior surface quality of cold-rolled steel makes it preferred for automotive panels, appliances, and furniture, where visual appeal is critical.

Strength and Performance Factors

Cold-rolled steel exhibits higher tensile strength and improved surface finish due to its refined grain structure, making it ideal for applications requiring precise dimensions and superior mechanical properties. Hot-rolled steel, while having lower tensile strength, offers greater ductility and better formability, suitable for construction and structural components where shape and size flexibility are essential. Performance factors such as yield strength, hardness, and dimensional accuracy significantly differ, with cold-rolled steel outperforming hot-rolled steel in strength-critical uses.

Applications of Cold-Rolled Steel

Cold-rolled steel offers superior surface finish and dimensional accuracy compared to hot-rolled steel, making it ideal for applications requiring high precision such as automotive panels, home appliances, and metal furniture. Its enhanced strength and smooth surface also benefit electrical cabinets and metal furniture production, where aesthetic quality and structural integrity are critical. Cold-rolled steel's improved mechanical properties enable its widespread use in manufacturing parts that demand uniform thickness and tight tolerances.

Applications of Hot-Rolled Steel

Hot-rolled steel is widely used in construction, automotive frames, and heavy machinery due to its high strength and malleability. Its ability to withstand extreme temperatures makes it ideal for structural components, railroad tracks, and shipbuilding. The rough surface finish of hot-rolled steel also suits applications where precise dimensions are less critical.

Cost Considerations and Market Availability

Cold-rolled steel generally incurs higher production costs due to the additional processing stages required to achieve its precise dimensions and smoother finish, making it more expensive than hot-rolled steel. Hot-rolled steel, benefitting from a simpler manufacturing process and larger production volumes, is more widely available and cost-effective for bulk applications. Market availability favors hot-rolled steel for structural and large-scale uses, while cold-rolled steel is preferred for applications demanding tighter tolerances despite its premium pricing.

Cold-rolled steel vs Hot-rolled steel Infographic

materialdif.com

materialdif.com