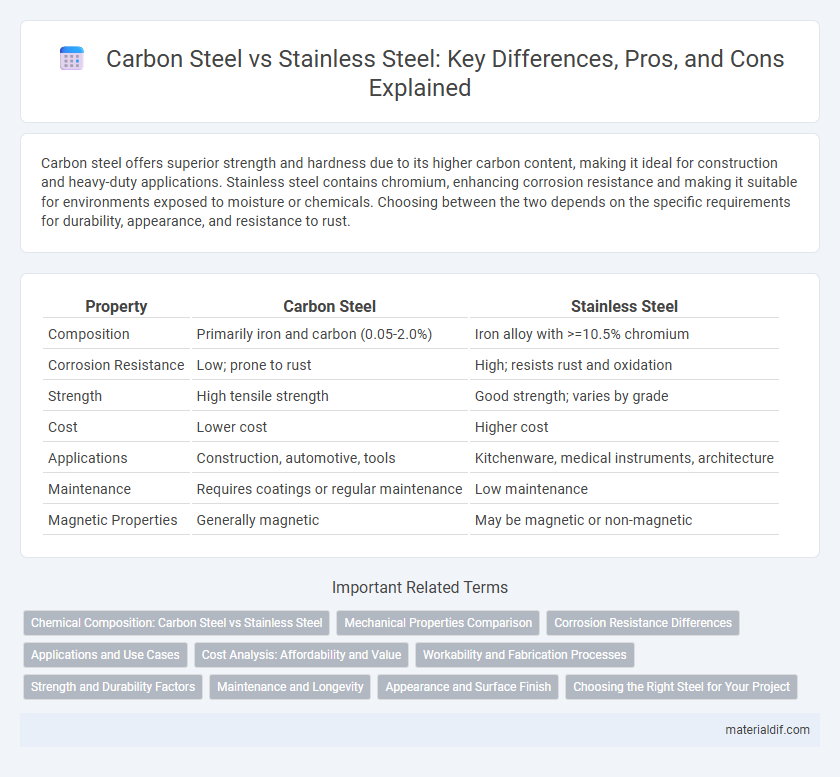

Carbon steel offers superior strength and hardness due to its higher carbon content, making it ideal for construction and heavy-duty applications. Stainless steel contains chromium, enhancing corrosion resistance and making it suitable for environments exposed to moisture or chemicals. Choosing between the two depends on the specific requirements for durability, appearance, and resistance to rust.

Table of Comparison

| Property | Carbon Steel | Stainless Steel |

|---|---|---|

| Composition | Primarily iron and carbon (0.05-2.0%) | Iron alloy with >=10.5% chromium |

| Corrosion Resistance | Low; prone to rust | High; resists rust and oxidation |

| Strength | High tensile strength | Good strength; varies by grade |

| Cost | Lower cost | Higher cost |

| Applications | Construction, automotive, tools | Kitchenware, medical instruments, architecture |

| Maintenance | Requires coatings or regular maintenance | Low maintenance |

| Magnetic Properties | Generally magnetic | May be magnetic or non-magnetic |

Chemical Composition: Carbon Steel vs Stainless Steel

Carbon steel primarily consists of iron and carbon, typically containing 0.05% to 2.0% carbon, which significantly enhances its hardness and strength but reduces corrosion resistance. Stainless steel contains at least 10.5% chromium, which forms a passive layer that prevents rust and provides excellent corrosion resistance, often combined with nickel, molybdenum, and other alloying elements to improve durability and performance. The distinct chemical compositions determine their suitability for applications requiring hardness and wear resistance versus corrosion resistance and aesthetic appeal.

Mechanical Properties Comparison

Carbon steel exhibits higher tensile strength and hardness due to its increased carbon content, making it suitable for applications requiring wear resistance and durability. Stainless steel, enriched with chromium, offers superior corrosion resistance and maintains toughness at varying temperatures, ideal for environments exposed to moisture and chemicals. While carbon steel can be prone to rust and less ductile, stainless steel provides enhanced ductility and impact resistance, important for structural and food-grade applications.

Corrosion Resistance Differences

Carbon steel exhibits lower corrosion resistance due to its higher iron content and lack of chromium, making it more susceptible to rust and oxidation when exposed to moisture and environmental elements. Stainless steel contains at least 10.5% chromium, forming a passive oxide layer that significantly enhances its corrosion resistance against humidity, acids, and other corrosive agents. This fundamental difference results in stainless steel being preferred for applications requiring durability in harsh conditions, while carbon steel is often chosen for its strength and cost-effectiveness in less corrosive environments.

Applications and Use Cases

Carbon steel is preferred in construction, automotive manufacturing, and heavy machinery due to its high strength, hardness, and cost-effectiveness, making it ideal for structural components and tools. Stainless steel, known for its corrosion resistance and aesthetic appeal, is widely used in kitchenware, medical instruments, food processing equipment, and chemical containers. Both materials serve critical roles in industrial and consumer applications, with carbon steel excelling in durability and stainless steel in hygiene and longevity.

Cost Analysis: Affordability and Value

Carbon steel typically offers a lower initial cost compared to stainless steel, making it more affordable for large-scale construction and manufacturing projects. Stainless steel provides greater corrosion resistance and durability, which can reduce long-term maintenance and replacement expenses, balancing its higher upfront investment. Evaluating total cost of ownership highlights that carbon steel suits budget-sensitive applications, while stainless steel delivers superior value in environments demanding longevity and strength.

Workability and Fabrication Processes

Carbon steel offers excellent workability due to its lower alloy content, enabling easier machining, welding, and forming compared to stainless steel. Stainless steel requires specialized fabrication processes like TIG welding and careful heat treatment to maintain corrosion resistance and structural integrity, often increasing production complexity. The choice between the two depends on balancing workability with performance requirements, where carbon steel excels in ease of fabrication and stainless steel provides superior durability and corrosion resistance.

Strength and Durability Factors

Carbon steel exhibits higher tensile strength and hardness compared to stainless steel, making it ideal for applications requiring robust mechanical performance. Stainless steel offers superior corrosion resistance and long-term durability in harsh environments due to its chromium content, which forms a passive oxide layer. The choice between carbon steel and stainless steel depends on the balance between strength requirements and exposure to corrosive elements.

Maintenance and Longevity

Carbon steel requires regular maintenance to prevent rust and corrosion, including frequent cleaning and protective coatings, especially in humid or harsh environments. Stainless steel offers superior corrosion resistance due to its chromium content, resulting in lower maintenance needs and extended longevity even in challenging conditions. The durability of stainless steel often justifies its higher initial cost by reducing repair and replacement frequency over time.

Appearance and Surface Finish

Carbon steel typically exhibits a darker, matte finish prone to rust and oxidation without protective coatings, making its appearance less uniform over time. Stainless steel features a bright, shiny surface with high corrosion resistance, maintaining a sleek and polished look through extended exposure to moisture and atmospheric conditions. The chromium content in stainless steel enhances its surface durability and aesthetic appeal, setting it apart from the more porous and reactive surface of carbon steel.

Choosing the Right Steel for Your Project

Carbon steel offers superior strength and affordability, making it ideal for structural applications and heavy-duty tools. Stainless steel provides exceptional corrosion resistance and a sleek finish, perfect for kitchenware, medical instruments, and outdoor projects. Selecting the right steel depends on balancing mechanical properties, environmental exposure, and budget requirements for your specific project.

Carbon steel vs Stainless steel Infographic

materialdif.com

materialdif.com