Ferritic steel offers excellent corrosion resistance and good ductility due to its body-centered cubic (BCC) crystal structure, making it suitable for automotive and industrial applications. Martensitic steel, characterized by its high hardness and strength from a carbon-rich, body-centered tetragonal (BCT) phase, is ideal for cutting tools and wear-resistant components. The choice between ferritic and martensitic steel depends on the required balance of toughness, hardness, and corrosion resistance for specific engineering needs.

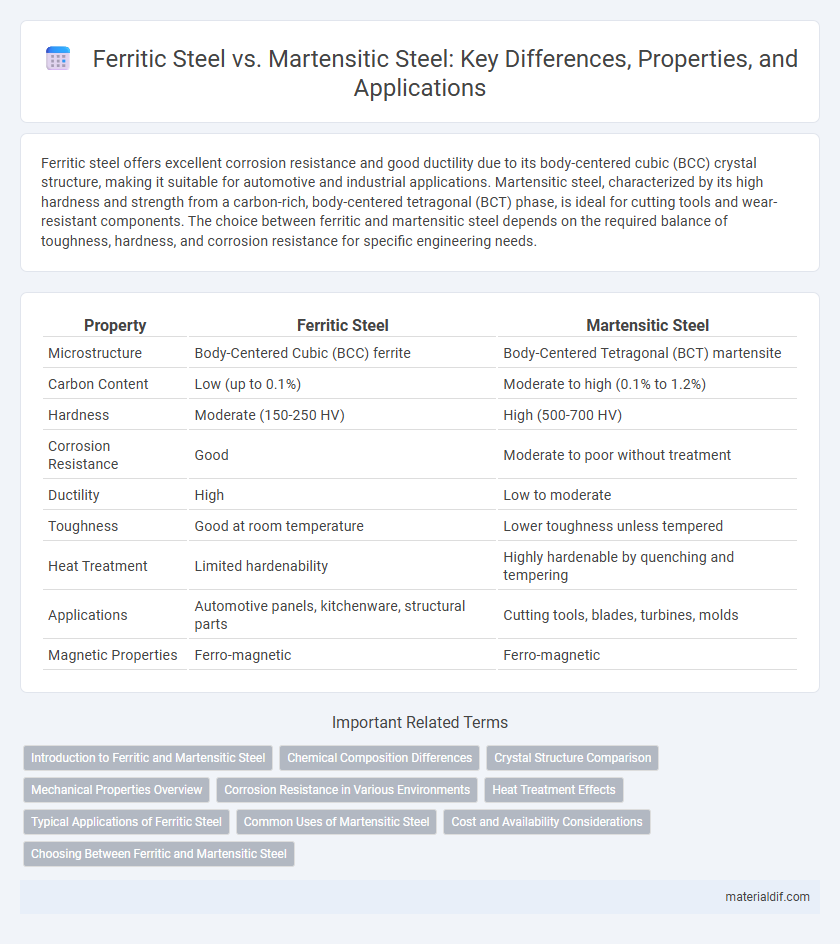

Table of Comparison

| Property | Ferritic Steel | Martensitic Steel |

|---|---|---|

| Microstructure | Body-Centered Cubic (BCC) ferrite | Body-Centered Tetragonal (BCT) martensite |

| Carbon Content | Low (up to 0.1%) | Moderate to high (0.1% to 1.2%) |

| Hardness | Moderate (150-250 HV) | High (500-700 HV) |

| Corrosion Resistance | Good | Moderate to poor without treatment |

| Ductility | High | Low to moderate |

| Toughness | Good at room temperature | Lower toughness unless tempered |

| Heat Treatment | Limited hardenability | Highly hardenable by quenching and tempering |

| Applications | Automotive panels, kitchenware, structural parts | Cutting tools, blades, turbines, molds |

| Magnetic Properties | Ferro-magnetic | Ferro-magnetic |

Introduction to Ferritic and Martensitic Steel

Ferritic steel is a type of stainless steel characterized by a body-centered cubic (BCC) crystal structure and primarily composed of iron and chromium, offering excellent corrosion resistance and magnetic properties. Martensitic steel features a body-centered tetragonal (BCT) structure formed by rapid quenching, resulting in high hardness and strength but lower corrosion resistance compared to ferritic steel. Both ferritic and martensitic steels serve critical roles in automotive, construction, and industrial applications, with their distinct microstructures influencing mechanical and chemical performance.

Chemical Composition Differences

Ferritic steel primarily contains 10.5-27% chromium and low carbon content, typically below 0.1%, which enhances its corrosion resistance and magnetic properties. Martensitic steel features higher carbon levels, generally between 0.1-1.2%, combined with chromium ranging from 11.5-18%, resulting in increased hardness and strength after heat treatment. The chemical composition distinctly influences their microstructure, with ferritic steel being nearly pure iron-chromium alloys and martensitic steel incorporating carbon to form a martensite phase during quenching.

Crystal Structure Comparison

Ferritic steel features a body-centered cubic (BCC) crystal structure that provides good ductility and resistance to corrosion, making it ideal for applications requiring toughness at elevated temperatures. Martensitic steel, characterized by a distorted body-centered tetragonal (BCT) crystal structure formed through rapid quenching, offers superior hardness and strength but lower corrosion resistance. The key difference in crystal structure significantly impacts their mechanical properties, with ferritic steels favoring formability and martensitic steels optimized for wear resistance.

Mechanical Properties Overview

Ferritic steel offers excellent ductility and moderate strength, making it suitable for applications requiring good corrosion resistance and formability. Martensitic steel exhibits higher hardness and tensile strength due to its carbon content and heat treatment, but it has reduced ductility and toughness compared to ferritic steel. The choice between ferritic and martensitic steel depends on balancing mechanical properties like strength, hardness, and impact resistance for specific engineering applications.

Corrosion Resistance in Various Environments

Ferritic steel exhibits superior corrosion resistance in oxidizing environments due to its higher chromium content and stable ferrite phase, making it ideal for applications exposed to atmospheric and mild acidic conditions. Martensitic steel, while offering excellent hardness and strength, is more susceptible to corrosion, especially in chloride-rich and highly acidic environments, due to its carbon-enriched martensitic microstructure. Selecting ferritic steel over martensitic steel enhances durability and reduces maintenance costs in corrosive settings such as marine atmospheres and chemical processing industries.

Heat Treatment Effects

Heat treatment significantly alters the microstructure and mechanical properties of ferritic and martensitic steels, with ferritic steel typically undergoing processes like annealing to enhance ductility and reduce hardness. Martensitic steel responds to quenching and tempering by transforming its microstructure into a harder, stronger state due to the formation of martensite, which increases tensile strength and wear resistance. These heat treatment effects make ferritic steels ideal for applications requiring toughness and corrosion resistance, while martensitic steels excel in situations demanding high hardness and strength.

Typical Applications of Ferritic Steel

Ferritic steel, known for its excellent corrosion resistance and magnetic properties, is widely used in automotive exhaust systems, industrial equipment, and heat exchangers. Its low carbon content enhances formability and weldability, making it ideal for structural components in appliances and construction. Typical applications also include kitchenware, piping, and automotive trim parts, benefiting from its toughness and resistance to oxidation.

Common Uses of Martensitic Steel

Martensitic steel is widely used in applications requiring high strength and wear resistance, such as cutting tools, surgical instruments, and turbine blades. Its unique hardness and toughness make it ideal for manufacturing knives, automotive components, and aerospace parts that endure high stress and impact. The steel's ability to be heat-treated to various hardness levels enhances its versatility across industrial sectors.

Cost and Availability Considerations

Ferritic steel generally offers lower cost and higher availability due to its simpler manufacturing process and widespread use in automotive and construction industries. Martensitic steel, while more expensive and less abundant, provides superior hardness and strength, making it ideal for high-performance tools and wear-resistant applications. The cost difference stems from the heat treatment and alloying elements required for martensitic steel, impacting overall production expenses and market supply.

Choosing Between Ferritic and Martensitic Steel

Choosing between ferritic and martensitic steel depends on the required mechanical properties and corrosion resistance. Ferritic steel offers excellent resistance to stress corrosion cracking and better ductility, making it ideal for automotive and structural applications. Martensitic steel provides higher hardness and strength due to its carbon content, suitable for cutting tools, blades, and wear-resistant parts.

Ferritic Steel vs Martensitic Steel Infographic

materialdif.com

materialdif.com