Alloy steel contains additional elements such as chromium, nickel, and manganese that enhance its strength, toughness, and corrosion resistance compared to plain steel. Plain steel, primarily composed of iron and carbon, offers good machinability and cost-effectiveness but lacks the superior mechanical properties of alloy steel. Choosing between the two depends on the specific application requirements, including durability, strength, and environmental conditions.

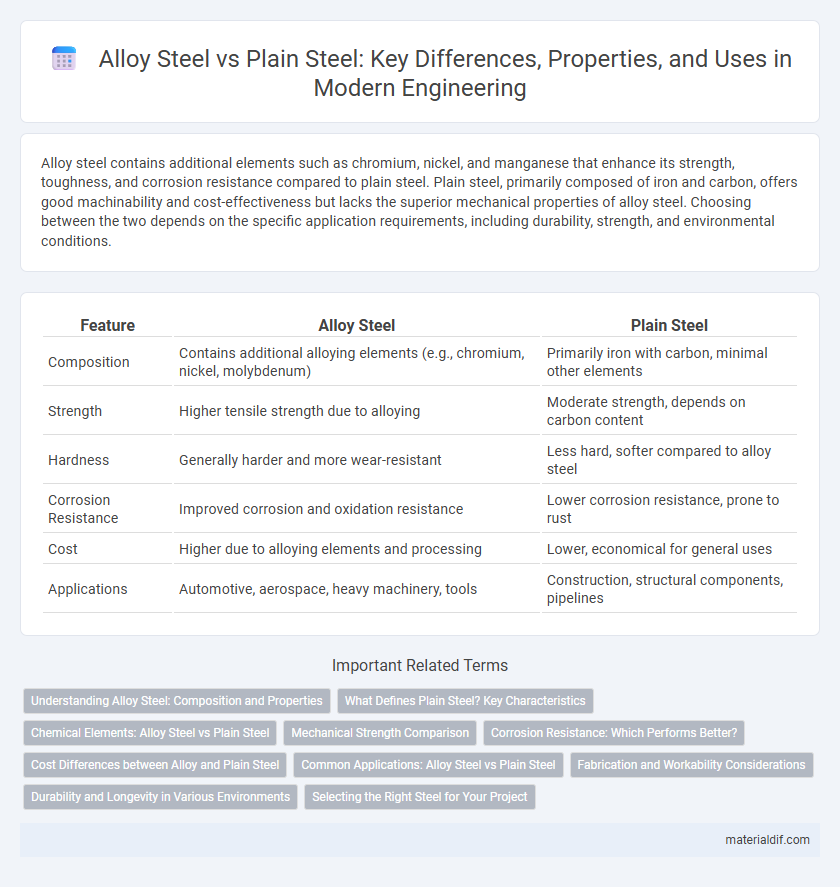

Table of Comparison

| Feature | Alloy Steel | Plain Steel |

|---|---|---|

| Composition | Contains additional alloying elements (e.g., chromium, nickel, molybdenum) | Primarily iron with carbon, minimal other elements |

| Strength | Higher tensile strength due to alloying | Moderate strength, depends on carbon content |

| Hardness | Generally harder and more wear-resistant | Less hard, softer compared to alloy steel |

| Corrosion Resistance | Improved corrosion and oxidation resistance | Lower corrosion resistance, prone to rust |

| Cost | Higher due to alloying elements and processing | Lower, economical for general uses |

| Applications | Automotive, aerospace, heavy machinery, tools | Construction, structural components, pipelines |

Understanding Alloy Steel: Composition and Properties

Alloy steel contains specific elements such as chromium, nickel, and molybdenum, which enhance its mechanical properties and corrosion resistance compared to plain steel. The varied composition of alloy steel allows for improved strength, toughness, and wear resistance, making it suitable for demanding industrial applications. Plain steel, primarily composed of iron and carbon, offers basic strength but lacks the enhanced performance characteristics provided by alloying elements.

What Defines Plain Steel? Key Characteristics

Plain steel, also known as carbon steel, is defined by its composition primarily of iron and carbon, typically containing less than 2% carbon and minimal alloying elements. Its key characteristics include high tensile strength, good ductility, and excellent machinability, making it suitable for general construction and manufacturing purposes. Unlike alloy steel, plain steel lacks significant amounts of additional elements such as chromium, nickel, or molybdenum, which limits its corrosion resistance and specific mechanical properties.

Chemical Elements: Alloy Steel vs Plain Steel

Alloy steel contains significant amounts of elements like chromium, nickel, molybdenum, and vanadium, enhancing properties such as strength, hardness, and corrosion resistance compared to plain steel, which primarily consists of iron and carbon. The addition of these alloying elements in specific percentages alters the microstructure and mechanical behavior to suit various industrial applications. Plain steel, with its simpler chemical composition, typically offers lower cost and easier machinability but lacks the specialized performance characteristics provided by alloy steel's diverse elemental makeup.

Mechanical Strength Comparison

Alloy steel contains additional elements such as chromium, nickel, and molybdenum, enhancing its mechanical strength and hardness compared to plain steel, which is primarily composed of iron and carbon. The presence of these alloying elements improves tensile strength, toughness, and resistance to wear and fatigue, making alloy steel suitable for high-stress applications. Plain steel, while easier to weld and machine, generally exhibits lower yield strength and impact resistance than alloy steel.

Corrosion Resistance: Which Performs Better?

Alloy steel outperforms plain steel in corrosion resistance due to the presence of elements like chromium, nickel, and molybdenum that form a protective oxide layer on the surface. Plain steel, typically composed of carbon and iron, lacks these alloying elements and is more susceptible to rust and oxidization in harsh environments. In applications exposed to moisture and chemicals, alloy steel offers significantly enhanced durability and longevity compared to plain steel.

Cost Differences between Alloy and Plain Steel

Alloy steel typically incurs higher costs than plain steel due to the inclusion of additional elements such as chromium, nickel, and molybdenum, which enhance mechanical properties and corrosion resistance. The production process for alloy steel involves more complex refining and heat treatment, raising manufacturing expenses. Plain steel, composed mainly of iron and carbon, offers a more economical option for applications where superior strength and durability are less critical.

Common Applications: Alloy Steel vs Plain Steel

Alloy steel is commonly used in automotive parts, aerospace components, and heavy machinery due to its enhanced strength, toughness, and resistance to wear and corrosion. Plain steel, also known as carbon steel, is widely applied in construction, manufacturing of structural beams, and general-purpose tools because of its affordability and adequate mechanical properties. Selecting between alloy steel and plain steel depends on the specific application requirements such as durability, environmental conditions, and performance standards.

Fabrication and Workability Considerations

Alloy steel offers enhanced fabrication versatility due to its improved mechanical properties like increased strength and corrosion resistance, making it ideal for complex welding and machining processes. Plain steel provides superior workability with easier cutting, bending, and forming, often preferred for simpler manufacturing tasks. Choosing between alloy steel and plain steel depends on the required balance of durability, fabrication complexity, and cost-effectiveness in the application.

Durability and Longevity in Various Environments

Alloy steel offers superior durability and extended longevity compared to plain steel due to its enhanced resistance to corrosion, wear, and high temperatures, making it ideal for harsh and variable environments. The addition of elements like chromium, nickel, and molybdenum in alloy steel improves its mechanical properties and performance in demanding applications such as construction, automotive, and industrial machinery. Plain steel, while cost-effective for general use, lacks the specialized resilience and environmental adaptability found in alloy steel, leading to faster degradation under extreme conditions.

Selecting the Right Steel for Your Project

Alloy steel contains additional elements such as chromium, nickel, and molybdenum, enhancing its strength, corrosion resistance, and machinability compared to plain carbon steel, which primarily consists of iron and carbon. Selecting the right steel depends on project requirements including mechanical properties, environmental conditions, and cost-effectiveness; alloy steel is preferable for applications needing superior durability and resistance, while plain steel suits structural uses with moderate strength demands. Understanding the specific alloy composition and performance characteristics ensures optimal material selection for longevity and reliability in construction, manufacturing, or engineering projects.

Alloy Steel vs Plain Steel Infographic

materialdif.com

materialdif.com