Type 304 stainless steel offers excellent corrosion resistance and is widely used in kitchen appliances and food processing equipment, while Type 316 contains molybdenum, enhancing its resistance to chloride environments and making it ideal for marine applications. The higher nickel content in 316 stainless steel also provides better durability against harsh chemicals and high temperatures. Choosing between 304 and 316 depends on the specific environmental conditions and corrosion resistance requirements of the project.

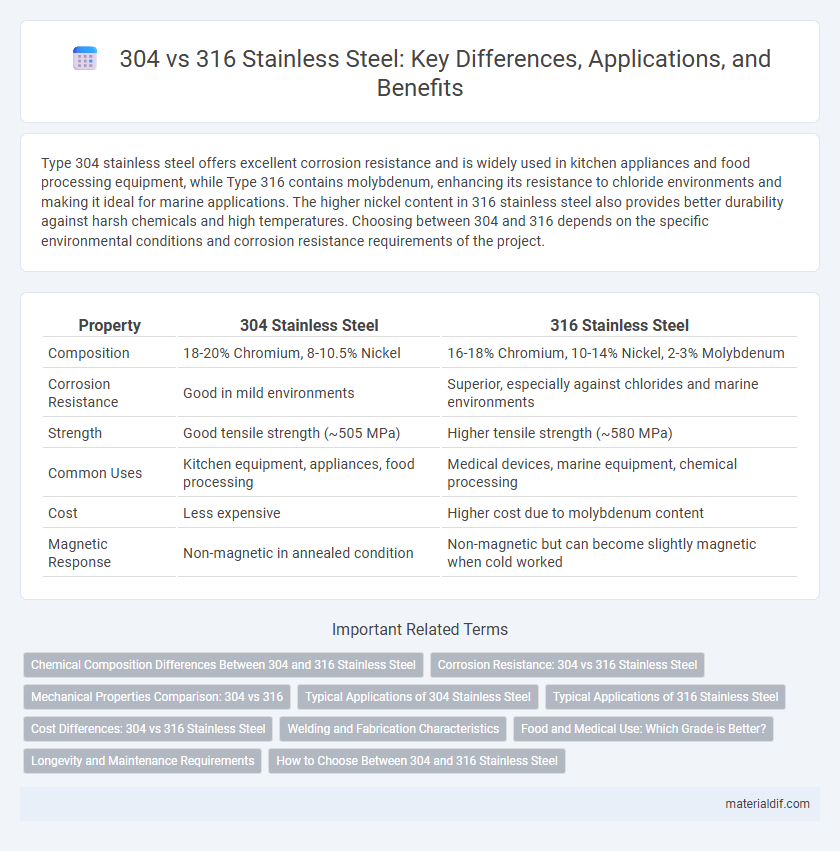

Table of Comparison

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Composition | 18-20% Chromium, 8-10.5% Nickel | 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum |

| Corrosion Resistance | Good in mild environments | Superior, especially against chlorides and marine environments |

| Strength | Good tensile strength (~505 MPa) | Higher tensile strength (~580 MPa) |

| Common Uses | Kitchen equipment, appliances, food processing | Medical devices, marine equipment, chemical processing |

| Cost | Less expensive | Higher cost due to molybdenum content |

| Magnetic Response | Non-magnetic in annealed condition | Non-magnetic but can become slightly magnetic when cold worked |

Chemical Composition Differences Between 304 and 316 Stainless Steel

304 stainless steel primarily contains 18-20% chromium and 8-10.5% nickel, while 316 stainless steel includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum in 316 enhances corrosion resistance, especially against chlorides and marine environments. Differences in carbon content also influence strength and corrosion resistance, with 316 typically exhibiting superior performance in harsh conditions.

Corrosion Resistance: 304 vs 316 Stainless Steel

316 stainless steel offers superior corrosion resistance compared to 304, especially in chloride-rich environments due to the addition of molybdenum, which enhances its resistance to pitting and crevice corrosion. 304 stainless steel corrodes more easily when exposed to saltwater or marine atmospheres, making 316 the preferred choice for marine and chemical applications. The higher corrosion resistance of 316 stainless steel extends its durability and lifespan in harsh environments, reducing maintenance costs.

Mechanical Properties Comparison: 304 vs 316

304 stainless steel offers tensile strength around 515 MPa and yield strength approximately 205 MPa, exhibiting excellent ductility and hardness suitable for general applications. In contrast, 316 stainless steel provides slightly higher tensile strength near 580 MPa and yield strength around 290 MPa, enhanced corrosion resistance, and superior performance in aggressive environments due to molybdenum content. The mechanical advantage of 316 stainless steel makes it preferable for marine, chemical, and high-temperature applications where increased strength and corrosion resistance are critical.

Typical Applications of 304 Stainless Steel

304 stainless steel is widely used in kitchen equipment, food processing appliances, and architectural applications due to its excellent corrosion resistance and ease of fabrication. It is commonly found in sinks, cookware, cutlery, and chemical containers where mild environments are present. Its versatility and cost-effectiveness make it suitable for automotive trim, handrails, and storage tanks.

Typical Applications of 316 Stainless Steel

316 stainless steel is widely used in marine environments, chemical processing, and pharmaceutical industries due to its superior corrosion resistance and molybdenum content. It is preferred for surgical instruments, food processing equipment, and outdoor architectural structures where exposure to saltwater and harsh chemicals is common. Compared to 304 stainless steel, 316 offers enhanced durability in chloride-rich conditions, making it ideal for heavy-duty applications requiring high corrosion resistance.

Cost Differences: 304 vs 316 Stainless Steel

304 stainless steel typically costs less than 316 due to its lower nickel and molybdenum content, making it a more budget-friendly option for applications with moderate corrosion resistance needs. In contrast, 316 stainless steel, enriched with molybdenum, offers superior resistance to chlorides and harsh environments, justifying its higher price in marine and chemical processing industries. The cost difference between 304 and 316 stainless steel can range from 20% to 50%, influenced by current market prices and alloy composition.

Welding and Fabrication Characteristics

Type 304 stainless steel offers excellent weldability with minimal risk of cracking, making it ideal for general fabrication and applications requiring complex joints. Type 316 stainless steel, containing molybdenum, provides superior corrosion resistance in harsh environments but demands controlled welding techniques to prevent sensitization and maintain strength. Both alloys respond well to common welding processes like TIG and MIG, although 316 may need post-weld heat treatment for optimal durability in aggressive conditions.

Food and Medical Use: Which Grade is Better?

Grade 304 stainless steel is widely used in food processing equipment due to its excellent corrosion resistance and ease of cleaning, making it ideal for most food and beverage applications. Grade 316 contains molybdenum, enhancing its resistance to chlorides and saline environments, which makes it more suitable for medical instruments and pharmaceutical equipment requiring high corrosion resistance. For high-salinity or harsh cleaning environments, 316 stainless steel offers better longevity and durability, whereas 304 remains a cost-effective choice for standard food processing uses.

Longevity and Maintenance Requirements

Type 316 stainless steel offers superior corrosion resistance compared to 304, making it ideal for harsh environments and extending longevity significantly. 304 stainless steel, while durable, requires more frequent maintenance to prevent rust and degradation, especially in marine or chemical settings. Choosing 316 minimizes upkeep costs and enhances lifespan in applications exposed to chloride and acidic conditions.

How to Choose Between 304 and 316 Stainless Steel

Choosing between 304 and 316 stainless steel depends on the specific environmental conditions and corrosion resistance requirements. 304 stainless steel is ideal for general indoor applications due to its excellent resistance to oxidation and corrosion in mildly corrosive environments. 316 stainless steel contains molybdenum, enhancing its resistance to chlorides and marine environments, making it the preferred option for saltwater exposure or harsh chemical conditions.

304 vs 316 Infographic

materialdif.com

materialdif.com