Galvanized steel is coated with a layer of zinc to provide enhanced corrosion resistance, making it ideal for outdoor and industrial applications. Non-galvanized steel lacks this protective coating, which can lead to rust and deterioration when exposed to moisture and harsh environments. Choosing between galvanized and non-galvanized steel depends on the specific durability requirements and environmental conditions of the project.

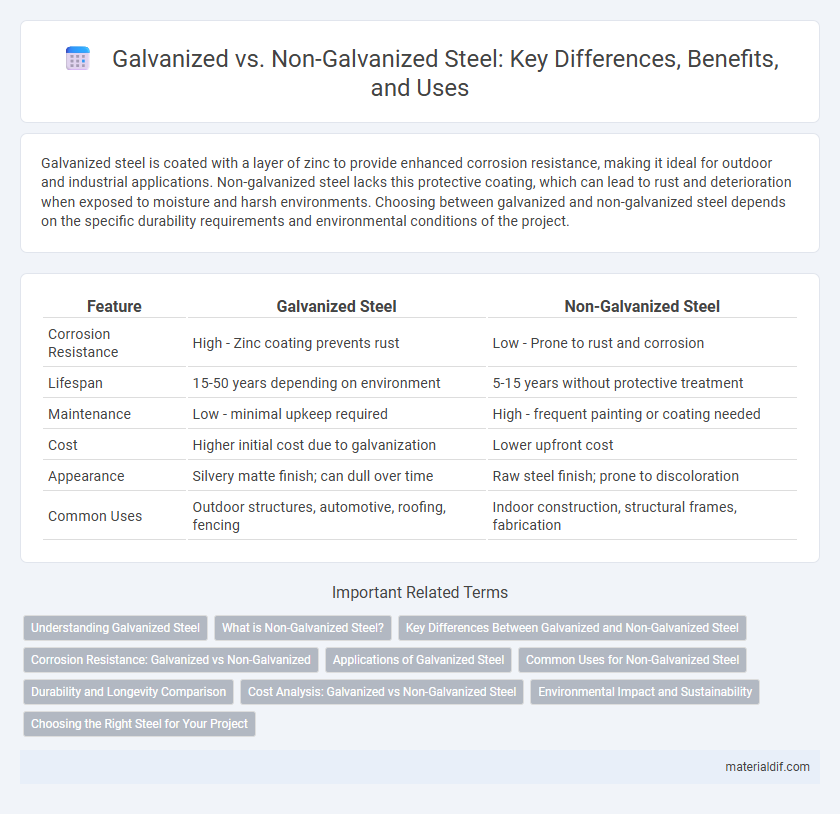

Table of Comparison

| Feature | Galvanized Steel | Non-Galvanized Steel |

|---|---|---|

| Corrosion Resistance | High - Zinc coating prevents rust | Low - Prone to rust and corrosion |

| Lifespan | 15-50 years depending on environment | 5-15 years without protective treatment |

| Maintenance | Low - minimal upkeep required | High - frequent painting or coating needed |

| Cost | Higher initial cost due to galvanization | Lower upfront cost |

| Appearance | Silvery matte finish; can dull over time | Raw steel finish; prone to discoloration |

| Common Uses | Outdoor structures, automotive, roofing, fencing | Indoor construction, structural frames, fabrication |

Understanding Galvanized Steel

Galvanized steel undergoes a protective zinc coating process that prevents rust and corrosion, significantly enhancing its durability in outdoor and humid environments. This zinc layer acts as a barrier and sacrifices itself through galvanic corrosion, extending the steel's lifespan compared to non-galvanized steel. Non-galvanized steel lacks this coating, requiring additional treatments or maintenance to protect against oxidation and structural damage over time.

What is Non-Galvanized Steel?

Non-galvanized steel refers to steel that has not undergone the galvanization process, leaving its surface untreated and more susceptible to rust and corrosion. This type of steel is typically used in applications where protective coatings are unnecessary or where cost reduction is a priority. In contrast to galvanized steel, non-galvanized steel requires additional protective measures such as painting or sealing to prevent degradation in harsh environments.

Key Differences Between Galvanized and Non-Galvanized Steel

Galvanized steel is coated with a layer of zinc to provide enhanced corrosion resistance compared to non-galvanized steel, which lacks this protective barrier. This zinc coating significantly extends the lifespan of steel in outdoor and humid environments by preventing rust formation. Non-galvanized steel is typically used in indoor applications or where the material will be painted or otherwise protected from moisture exposure.

Corrosion Resistance: Galvanized vs Non-Galvanized

Galvanized steel features a protective zinc coating that significantly enhances corrosion resistance by preventing moisture and oxygen from reaching the underlying metal, reducing rust formation and extending the material's lifespan. Non-galvanized steel lacks this protective layer, making it more vulnerable to corrosion when exposed to moisture, humidity, and environmental pollutants, which accelerates deterioration. The choice between galvanized and non-galvanized steel is critical in applications requiring durability in harsh or outdoor environments, where corrosion resistance directly impacts maintenance costs and structural integrity.

Applications of Galvanized Steel

Galvanized steel is widely used in construction, automotive manufacturing, and outdoor infrastructure due to its corrosion resistance and durability. Its zinc coating protects steel from rust, making it ideal for roofing, fencing, and electrical panel enclosures exposed to harsh environments. Compared to non-galvanized steel, galvanized steel requires less maintenance and offers longer service life in applications where moisture and weather exposure are concerns.

Common Uses for Non-Galvanized Steel

Non-galvanized steel is commonly used in structural applications such as building frames, bridges, and machinery where corrosion resistance is not a primary concern. It is favored in manufacturing components like automotive parts, heavy equipment, and industrial tools due to its strength and cost-effectiveness. Non-galvanized steel is also widely utilized in indoor environments or locations with controlled conditions, minimizing exposure to moisture and reducing the risk of rust.

Durability and Longevity Comparison

Galvanized steel offers superior durability and longevity compared to non-galvanized steel due to its protective zinc coating that prevents rust and corrosion. Non-galvanized steel is more susceptible to environmental damage, leading to faster deterioration and reduced lifespan, especially in moist or corrosive conditions. The zinc layer on galvanized steel extends its functional life significantly, making it the preferred choice for outdoor and industrial applications requiring long-term performance.

Cost Analysis: Galvanized vs Non-Galvanized Steel

Galvanized steel generally incurs higher upfront costs due to the zinc coating process, which enhances corrosion resistance and extends material lifespan. Non-galvanized steel has lower initial expenses but often leads to increased maintenance and replacement costs over time due to rust and degradation. Considering lifecycle cost analysis, galvanized steel provides better value in environments prone to moisture or harsh conditions, reducing total ownership costs despite the initial premium.

Environmental Impact and Sustainability

Galvanized steel offers enhanced corrosion resistance by applying a protective zinc coating, significantly extending the material's lifespan and reducing the frequency of replacements compared to non-galvanized steel. The zinc coating used in galvanization is recyclable and contributes to lower environmental impact by minimizing resource consumption and waste. Non-galvanized steel tends to corrode faster, increasing maintenance needs and generating more environmental waste, thereby posing challenges for sustainable steel applications.

Choosing the Right Steel for Your Project

Galvanized steel offers superior corrosion resistance due to its protective zinc coating, making it ideal for outdoor or high-moisture environments. Non-galvanized steel is generally more cost-effective and suitable for indoor applications where exposure to elements is minimal. Evaluating project requirements for durability, environmental exposure, and budget helps determine the best choice between galvanized and non-galvanized steel.

Galvanized vs Non-galvanized Infographic

materialdif.com

materialdif.com