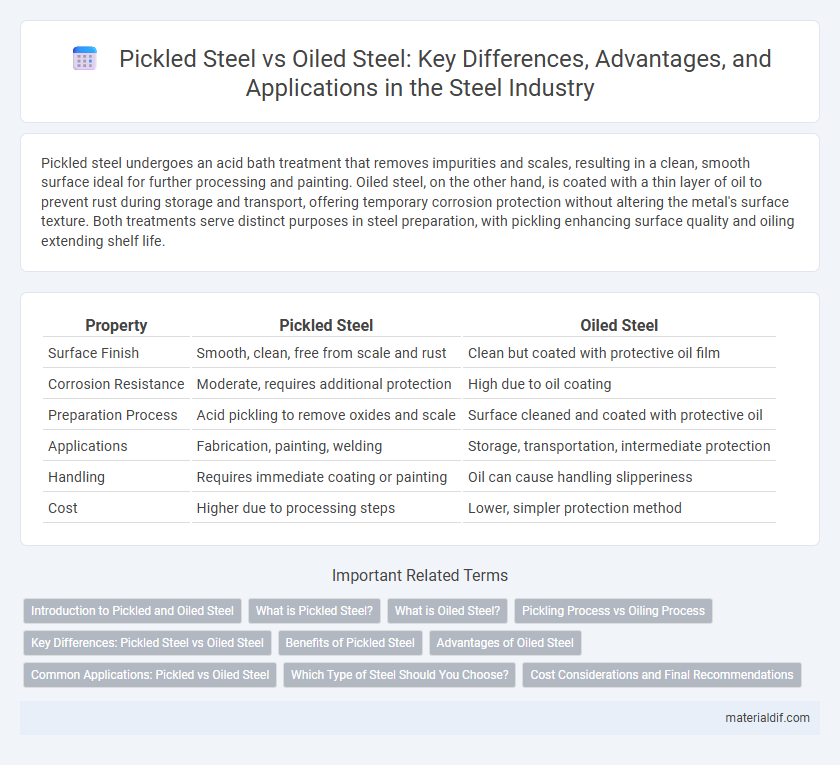

Pickled steel undergoes an acid bath treatment that removes impurities and scales, resulting in a clean, smooth surface ideal for further processing and painting. Oiled steel, on the other hand, is coated with a thin layer of oil to prevent rust during storage and transport, offering temporary corrosion protection without altering the metal's surface texture. Both treatments serve distinct purposes in steel preparation, with pickling enhancing surface quality and oiling extending shelf life.

Table of Comparison

| Property | Pickled Steel | Oiled Steel |

|---|---|---|

| Surface Finish | Smooth, clean, free from scale and rust | Clean but coated with protective oil film |

| Corrosion Resistance | Moderate, requires additional protection | High due to oil coating |

| Preparation Process | Acid pickling to remove oxides and scale | Surface cleaned and coated with protective oil |

| Applications | Fabrication, painting, welding | Storage, transportation, intermediate protection |

| Handling | Requires immediate coating or painting | Oil can cause handling slipperiness |

| Cost | Higher due to processing steps | Lower, simpler protection method |

Introduction to Pickled and Oiled Steel

Pickled steel undergoes an acid treatment process that removes surface impurities, rust, and scale, producing a clean, bright surface ideal for further processing and coating adherence. Oiled steel, on the other hand, is coated with a protective layer of oil to prevent corrosion during storage and transportation without altering the surface finish. These treatments influence the steel's corrosion resistance, surface quality, and suitability for various manufacturing applications.

What is Pickled Steel?

Pickled steel is a type of steel that has undergone an acid treatment to remove scale, rust, and impurities from the surface, resulting in a clean and smooth finish. This process enhances the steel's quality by preparing it for further processing, such as cold rolling or painting. Pickled steel offers superior corrosion resistance and improved adhesion compared to oiled steel, which is coated with a protective oil layer to prevent rust but retains surface scale.

What is Oiled Steel?

Oiled steel is a type of carbon steel that has been coated with a protective layer of oil to prevent rust and corrosion during storage and transportation. This oily film acts as a barrier against moisture and air, preserving the steel's surface integrity without altering its mechanical properties. Commonly used in construction and manufacturing, oiled steel requires cleaning before further processing or painting to ensure proper adhesion.

Pickling Process vs Oiling Process

The pickling process involves treating steel with acidic solutions like hydrochloric or sulfuric acid to remove surface impurities such as rust, scale, and oxides, resulting in a clean and smooth finish. In contrast, the oiling process applies a thin layer of protective oil or lubricant to the steel surface to prevent oxidation and corrosion during storage and transportation. Pickled steel is primarily prepared for further processing or finishing, while oiled steel is preserved to maintain its condition until use.

Key Differences: Pickled Steel vs Oiled Steel

Pickled steel undergoes an acid bath process to remove surface impurities such as rust and mill scale, resulting in a clean, bright finish ideal for further processing like painting or coating. Oiled steel, on the other hand, is coated with a thin layer of oil to prevent oxidation and corrosion during storage and transportation, providing protection but retaining its original surface roughness. The key differences lie in surface treatment and protection methods, where pickled steel offers a clean surface for enhanced adhesion, while oiled steel prioritizes rust prevention.

Benefits of Pickled Steel

Pickled steel undergoes an acid treatment that effectively removes scale, rust, and contaminants, resulting in a clean, smooth surface ideal for high-quality painting and coating applications. This process enhances surface uniformity and adhesion properties, reducing the risk of defects in subsequent manufacturing steps. Compared to oiled steel, pickled steel minimizes surface imperfections and improves overall product durability and aesthetic appeal.

Advantages of Oiled Steel

Oiled steel offers superior corrosion resistance compared to pickled steel, as the oil coating acts as a protective barrier against moisture and environmental contaminants. The oil layer also facilitates easier handling and reduces surface damage during transport and storage. Furthermore, oiled steel requires less surface preparation before further processing or coating, enhancing overall efficiency in manufacturing workflows.

Common Applications: Pickled vs Oiled Steel

Pickled steel is commonly used in automotive manufacturing, construction, and appliance production due to its clean, rust-free surface ideal for painting and welding. Oiled steel is typically utilized in storage, shipping, and heavy machinery where temporary corrosion resistance is needed before further processing. The choice between pickled and oiled steel depends on the environmental exposure and the specific requirements of downstream fabrication or finishing processes.

Which Type of Steel Should You Choose?

Pickled steel offers a clean, smooth surface free from mill scale, making it ideal for applications requiring precise coatings or painting. Oiled steel retains a protective layer of oil to prevent rust during storage and transportation, better suited for projects where immediate surface treatment isn't necessary. Choosing between pickled and oiled steel depends on the specific needs of corrosion resistance, surface finish, and preparation for subsequent processing.

Cost Considerations and Final Recommendations

Pickled steel generally incurs higher initial costs due to the chemical cleaning process used to remove scale and impurities, improving surface quality but increasing production expenses compared to oiled steel. Oiled steel, coated with a thin layer of protective oil, offers a cost-effective solution for corrosion resistance, although it may require more frequent maintenance or additional finishing treatments. For projects prioritizing superior surface finish and durability, pickled steel is recommended despite higher upfront costs, while oiled steel suits budget-conscious applications with less stringent aesthetic demands.

Pickled steel vs Oiled steel Infographic

materialdif.com

materialdif.com