Powder metallurgy steel offers superior uniformity in composition and microstructure compared to cast steel, resulting in enhanced mechanical properties and reduced defects. Its manufacturing process allows for precise control over alloying elements and porosity, making it ideal for complex shapes and high-performance applications. In contrast, cast steel is more cost-effective for large, simple components but often exhibits coarser grain structures and potential casting imperfections.

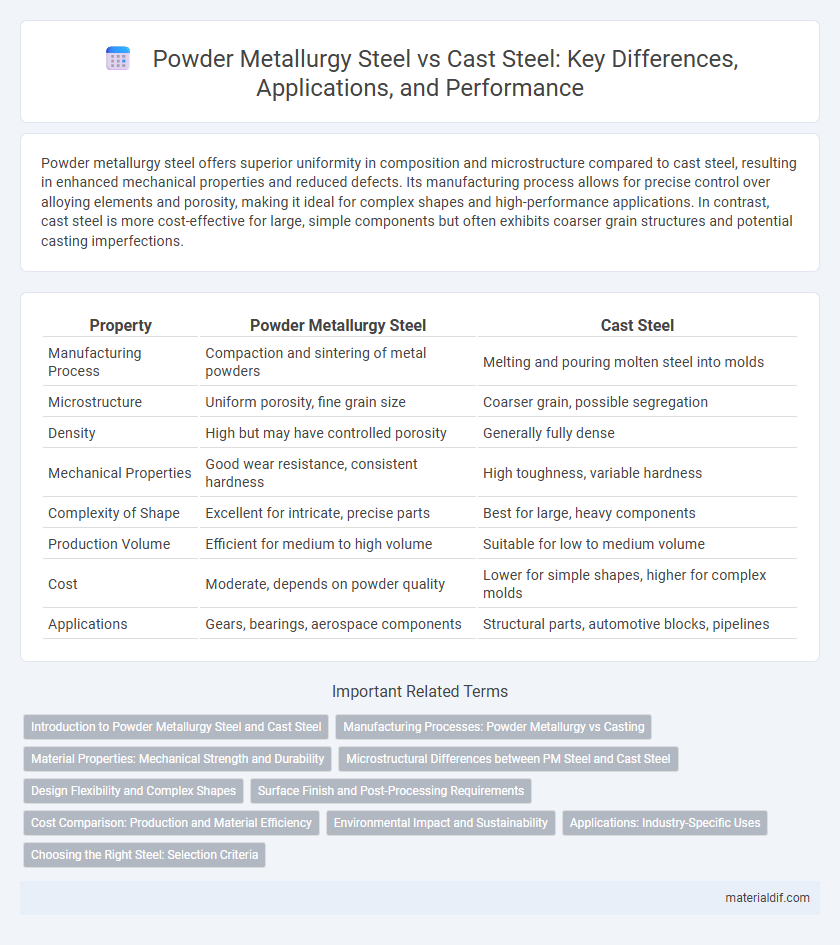

Table of Comparison

| Property | Powder Metallurgy Steel | Cast Steel |

|---|---|---|

| Manufacturing Process | Compaction and sintering of metal powders | Melting and pouring molten steel into molds |

| Microstructure | Uniform porosity, fine grain size | Coarser grain, possible segregation |

| Density | High but may have controlled porosity | Generally fully dense |

| Mechanical Properties | Good wear resistance, consistent hardness | High toughness, variable hardness |

| Complexity of Shape | Excellent for intricate, precise parts | Best for large, heavy components |

| Production Volume | Efficient for medium to high volume | Suitable for low to medium volume |

| Cost | Moderate, depends on powder quality | Lower for simple shapes, higher for complex molds |

| Applications | Gears, bearings, aerospace components | Structural parts, automotive blocks, pipelines |

Introduction to Powder Metallurgy Steel and Cast Steel

Powder metallurgy steel is produced by pressing and sintering fine metal powders, offering superior control over material composition and uniform microstructure compared to cast steel. Cast steel is formed by melting and pouring liquid metal into molds, resulting in complex shapes but with potential for internal defects and less homogeneity. The powder metallurgy process enables manufacturing of high-performance components with enhanced mechanical properties and reduced material waste versus traditional casting.

Manufacturing Processes: Powder Metallurgy vs Casting

Powder metallurgy steel involves blending fine metal powders, compacting them under high pressure, and sintering to form a dense, uniform material with precise control over composition and microstructure. Cast steel manufacturing melts raw steel and pours it into molds to solidify, allowing complex shapes but with potential porosity and less uniformity. The powder metallurgy process offers superior material properties and dimensional accuracy compared to the traditional casting method, which is more suited for larger component production.

Material Properties: Mechanical Strength and Durability

Powder metallurgy steel exhibits superior mechanical strength and enhanced durability due to its fine, uniform microstructure and controlled porosity, which minimize defects commonly found in cast steel. Cast steel, while generally tougher in bulk applications, often contains larger grain structures and internal flaws that can reduce its fatigue resistance and impact toughness. Optimizing powder metallurgy parameters can tailor the steel's mechanical properties for high-performance demands, surpassing cast steel in wear resistance and structural integrity.

Microstructural Differences between PM Steel and Cast Steel

Powder metallurgy (PM) steel exhibits a more uniform microstructure with fine, evenly distributed grains and minimal segregation compared to cast steel, which often contains coarse dendritic structures and microsegregation due to slower cooling rates. The porosity in PM steel is typically controlled and minimal, enhancing mechanical properties such as fatigue resistance, while cast steel may contain larger pores and inclusions that act as stress concentrators. Grain refinement in PM steel results from the powder consolidation process, promoting improved isotropic mechanical behavior relative to the anisotropic properties found in cast steel microstructures.

Design Flexibility and Complex Shapes

Powder metallurgy steel offers superior design flexibility compared to cast steel, enabling the production of intricate and complex shapes with high precision and minimal material waste. This method allows for uniform microstructure and enhanced mechanical properties in components with thin walls or delicate geometries that are difficult to achieve through casting. Cast steel, while effective for larger and simpler shapes, often faces limitations in producing detailed features due to mold constraints and shrinkage during solidification.

Surface Finish and Post-Processing Requirements

Powder metallurgy steel offers superior surface finish compared to cast steel due to its fine, uniform microstructure that minimizes surface imperfections. Cast steel typically requires extensive post-processing such as machining, grinding, and polishing to achieve comparable surface quality. The reduced need for secondary operations in powder metallurgy steel results in lower manufacturing costs and improved dimensional accuracy.

Cost Comparison: Production and Material Efficiency

Powder metallurgy steel offers superior material efficiency by minimizing waste through precise powder compaction and near-net shape forming, which significantly lowers raw material costs compared to cast steel. Production costs for powder metallurgy steel can be higher due to specialized equipment and processes, but reduced machining and finishing expenses often offset these initial investments. Cast steel involves simpler, less costly molding but results in more material scrap and rework, increasing overall expenditure in large-scale manufacturing.

Environmental Impact and Sustainability

Powder metallurgy steel reduces material waste by using precise amounts of metal powders, minimizing energy consumption compared to cast steel, which requires high-temperature melting processes. The lower emissions and reduced need for machining make powder metallurgy steel a more sustainable option with a smaller carbon footprint. Cast steel, while durable, involves significant energy-intensive melting and molding steps contributing to higher environmental impact.

Applications: Industry-Specific Uses

Powder metallurgy steel is widely used in automotive and aerospace industries for manufacturing complex, high-strength components such as gears, bearings, and turbine blades due to its precise control over material properties and minimal waste. Cast steel is predominantly employed in heavy machinery, construction, and pipeline industries, where large, robust parts like valves, pumps, and structural components are required for durability and impact resistance. The choice between powder metallurgy steel and cast steel depends on the application's demand for precision, mechanical properties, and production volume.

Choosing the Right Steel: Selection Criteria

Powder metallurgy steel offers superior homogeneity, precise alloy control, and excellent wear resistance compared to cast steel, making it ideal for high-performance and complex components. Cast steel, known for its cost-effectiveness and good impact strength, is preferable in large-scale structural applications where dimensional complexity is lower. Selection criteria should prioritize mechanical properties, production volume, cost constraints, and required tolerances to optimize material performance and lifecycle.

Powder Metallurgy Steel vs Cast Steel Infographic

materialdif.com

materialdif.com