Powder metallurgy steel offers superior uniformity and enhanced mechanical properties compared to conventional steel due to its fine microstructure and controlled porosity. This manufacturing process allows for precise alloy composition and reduced material waste, making it ideal for complex shapes and high-performance applications. Conventional steel, while versatile and cost-effective, often requires subsequent machining and heat treatment to achieve similar strength and durability levels.

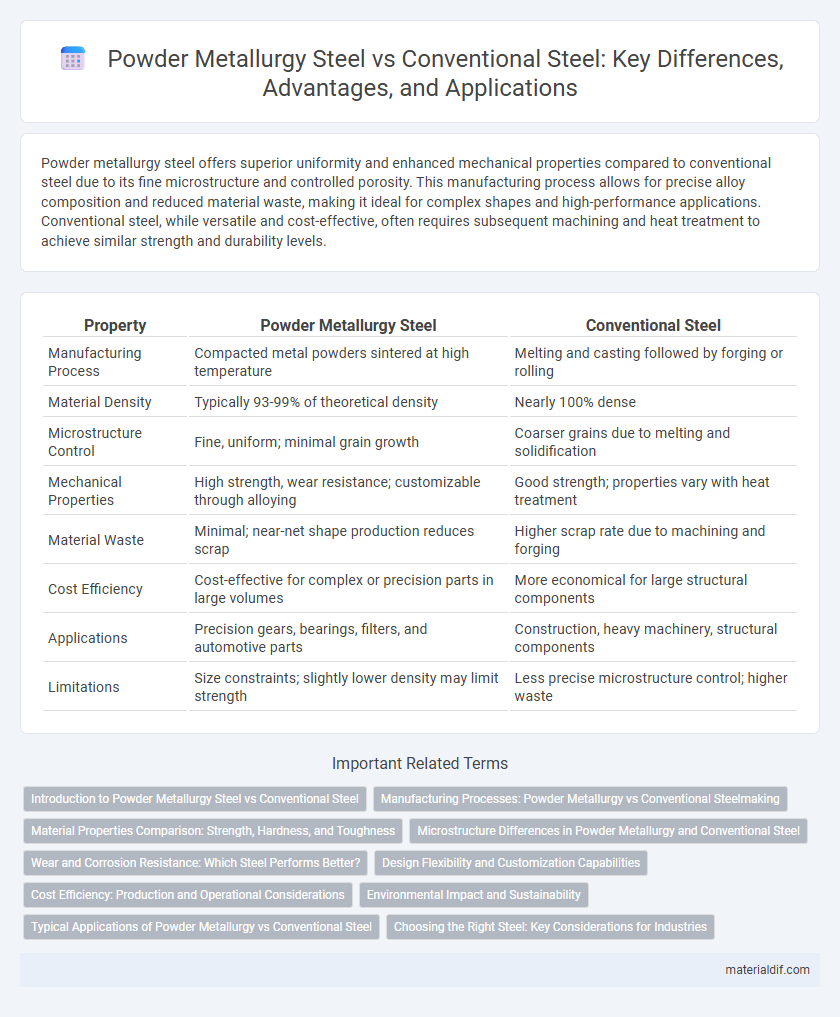

Table of Comparison

| Property | Powder Metallurgy Steel | Conventional Steel |

|---|---|---|

| Manufacturing Process | Compacted metal powders sintered at high temperature | Melting and casting followed by forging or rolling |

| Material Density | Typically 93-99% of theoretical density | Nearly 100% dense |

| Microstructure Control | Fine, uniform; minimal grain growth | Coarser grains due to melting and solidification |

| Mechanical Properties | High strength, wear resistance; customizable through alloying | Good strength; properties vary with heat treatment |

| Material Waste | Minimal; near-net shape production reduces scrap | Higher scrap rate due to machining and forging |

| Cost Efficiency | Cost-effective for complex or precision parts in large volumes | More economical for large structural components |

| Applications | Precision gears, bearings, filters, and automotive parts | Construction, heavy machinery, structural components |

| Limitations | Size constraints; slightly lower density may limit strength | Less precise microstructure control; higher waste |

Introduction to Powder Metallurgy Steel vs Conventional Steel

Powder metallurgy steel is manufactured by pressing and sintering powdered metal, offering enhanced uniformity, reduced waste, and superior mechanical properties compared to conventional steel formed through casting or forging. This process allows precise control over alloy composition and microstructure, resulting in improved wear resistance and strength. Conventional steel production involves melting raw materials, which may lead to inconsistencies and requires extensive machining to achieve final shapes.

Manufacturing Processes: Powder Metallurgy vs Conventional Steelmaking

Powder metallurgy steel is produced by compressing and sintering metal powders, allowing precise control over composition and microstructure, resulting in enhanced mechanical properties and reduced material waste. Conventional steelmaking involves melting and casting processes, where molten steel is poured into molds and subjected to rolling or forging, often leading to less uniform microstructures and higher energy consumption. The powder metallurgy process enables near-net shape production, minimizing machining requirements and providing superior material utilization compared to traditional steel manufacturing methods.

Material Properties Comparison: Strength, Hardness, and Toughness

Powder metallurgy steel exhibits superior strength and hardness compared to conventional steel due to its fine, uniform microstructure resulting from controlled sintering processes. It often demonstrates enhanced toughness by reducing porosity and enabling precise alloy composition control, which minimizes defects common in traditional casting or forging methods. Conventional steel may have variable mechanical properties influenced by heterogeneous grain structures and inconsistency in chemical composition distribution.

Microstructure Differences in Powder Metallurgy and Conventional Steel

Powder metallurgy steel exhibits a unique microstructure characterized by uniform grain distribution and reduced porosity due to the controlled consolidation of fine metal powders, resulting in enhanced mechanical properties. Conventional steel typically undergoes melting and solidification, leading to larger grain sizes and potential segregation or inclusions that affect toughness and strength. The homogeneity and refined microstructure of powder metallurgy steel contribute to superior wear resistance and fatigue strength compared to conventional steel.

Wear and Corrosion Resistance: Which Steel Performs Better?

Powder metallurgy steel exhibits superior wear resistance compared to conventional steel due to its uniform microstructure and fine carbide distribution, which reduce abrasive and adhesive wear. Corrosion resistance in powder metallurgy steel often surpasses that of conventional steel, as alloying elements are more evenly dispersed, enhancing the formation of protective oxide layers. The controlled porosity inherent in powder metallurgy steel can be optimized to improve corrosion resistance, making it preferable for applications involving harsh environments and extended service life.

Design Flexibility and Customization Capabilities

Powder metallurgy steel offers superior design flexibility and customization capabilities compared to conventional steel due to its ability to produce complex shapes with minimal machining and material waste. This method allows precise control over alloy composition and microstructure, enabling tailored mechanical properties for specific applications. Conventional steel typically requires extensive machining and welding to achieve complex designs, limiting customization and increasing production time and cost.

Cost Efficiency: Production and Operational Considerations

Powder metallurgy steel offers cost efficiency through reduced material waste and lower machining requirements compared to conventional steel, which often involves extensive cutting and shaping. Production processes for powder metallurgy steel enable near-net shaping, minimizing energy consumption and labor costs. Operationally, powder metallurgy steels provide consistent properties that reduce post-production treatments and maintenance expenses over time.

Environmental Impact and Sustainability

Powder metallurgy steel offers significant environmental advantages over conventional steel by minimizing raw material waste through near-net-shape manufacturing processes, reducing energy consumption by up to 30%, and lowering greenhouse gas emissions during production. Its ability to recycle scrap and scrap-like powders enhances sustainability compared to the higher waste and energy-intensive nature of traditional steelmaking methods. These efficiencies make powder metallurgy steel a more eco-friendly choice aligned with the goals for sustainable industrial practices.

Typical Applications of Powder Metallurgy vs Conventional Steel

Powder metallurgy steel is commonly used in applications requiring complex shapes and tight tolerances, such as automotive gears, cutting tools, and wear-resistant components. Conventional steel excels in structural applications like construction beams, pipelines, and heavy machinery where high strength and weldability are critical. Powder metallurgy offers advantages in reducing material waste and improving mechanical properties for precision parts, while conventional steel remains preferred for large, load-bearing frameworks.

Choosing the Right Steel: Key Considerations for Industries

Powder metallurgy steel offers superior uniformity and superior mechanical properties compared to conventional steel, making it ideal for applications requiring precise performance and wear resistance. Industries focused on high-strength, lightweight components benefit from powder metallurgy due to its enhanced microstructure and minimal material waste. Cost-effectiveness and production scalability remain critical factors when selecting between powder metallurgy steel and conventional steel for manufacturing processes.

Powder Metallurgy Steel vs Conventional Steel Infographic

materialdif.com

materialdif.com