Ferritic steel features a body-centered cubic (BCC) structure providing excellent ductility and corrosion resistance, making it ideal for applications requiring formability and toughness. Pearlitic steel contains alternating layers of ferrite and cementite, offering higher hardness and strength suitable for wear-resistant components and cutting tools. Choosing between ferritic and pearlitic steel depends on balancing the need for toughness versus strength in specific industrial applications.

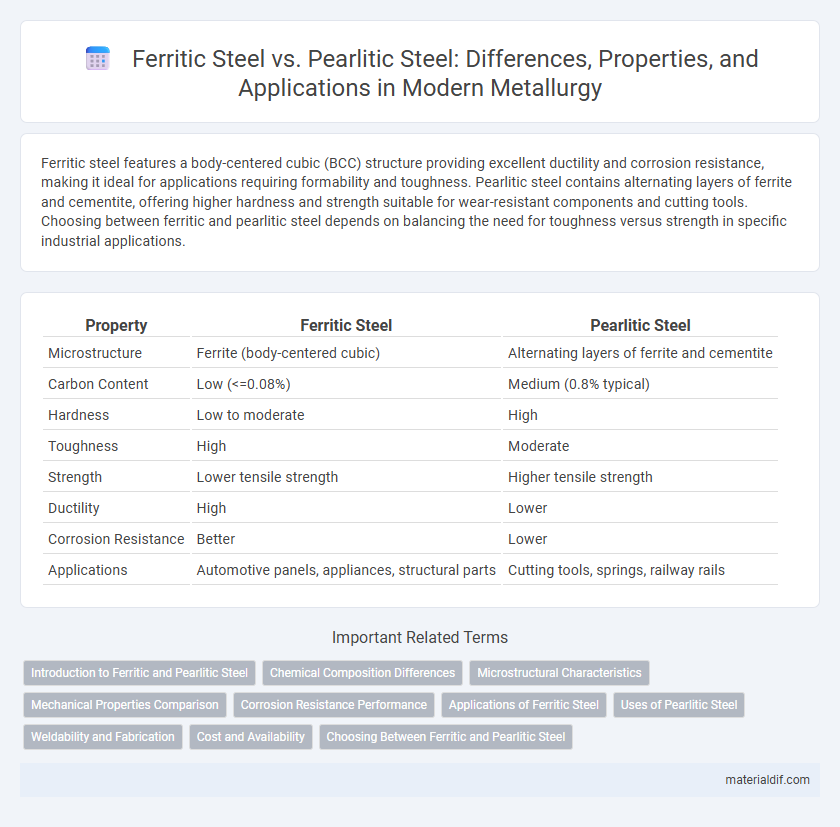

Table of Comparison

| Property | Ferritic Steel | Pearlitic Steel |

|---|---|---|

| Microstructure | Ferrite (body-centered cubic) | Alternating layers of ferrite and cementite |

| Carbon Content | Low (<=0.08%) | Medium (0.8% typical) |

| Hardness | Low to moderate | High |

| Toughness | High | Moderate |

| Strength | Lower tensile strength | Higher tensile strength |

| Ductility | High | Lower |

| Corrosion Resistance | Better | Lower |

| Applications | Automotive panels, appliances, structural parts | Cutting tools, springs, railway rails |

Introduction to Ferritic and Pearlitic Steel

Ferritic steel is characterized by a body-centered cubic (BCC) crystal structure, offering good ductility, corrosion resistance, and magnetic properties, making it suitable for automotive and structural applications. Pearlitic steel consists of alternating layers of ferrite and cementite, displaying superior strength and hardness due to its lamellar microstructure, commonly used in railway tracks and cutting tools. Understanding the distinct microstructures of ferritic and pearlitic steels is essential for optimizing mechanical performance and application-specific durability.

Chemical Composition Differences

Ferritic steel primarily consists of iron with a body-centered cubic (BCC) crystal structure and contains low carbon content, typically less than 0.02%, along with elements like chromium and manganese to enhance corrosion resistance and strength. Pearlitic steel features a higher carbon content, usually between 0.7% and 1.2%, resulting in a microstructure composed of alternating layers of ferrite and cementite that provide greater hardness and tensile strength. The significant variation in carbon percentage and alloying elements directly influences the mechanical properties and applications of ferritic versus pearlitic steel.

Microstructural Characteristics

Ferritic steel exhibits a body-centered cubic (BCC) microstructure with ferrite grains that provide high ductility and good corrosion resistance, characterized by relatively soft and magnetic properties. Pearlitic steel features a lamellar structure composed of alternating layers of ferrite and cementite, resulting in increased hardness and tensile strength but reduced ductility. The distinct microstructural differences between ferritic and pearlitic steels determine their suitability for applications requiring either toughness or wear resistance.

Mechanical Properties Comparison

Ferritic steel exhibits lower tensile strength but superior ductility and corrosion resistance compared to pearlitic steel, making it suitable for applications requiring toughness and formability. Pearlitic steel, characterized by its alternating layers of ferrite and cementite, offers higher hardness and wear resistance, ideal for tools and structural components subjected to heavy stress. The distinct microstructures of ferritic and pearlitic steels significantly influence their mechanical properties, with ferritic steel providing excellent impact resistance and pearlitic steel delivering enhanced strength and fatigue resistance.

Corrosion Resistance Performance

Ferritic steel exhibits superior corrosion resistance compared to pearlitic steel due to its higher chromium content and stable body-centered cubic (BCC) crystal structure, which enhances oxidation resistance in harsh environments. Pearlitic steel, characterized by alternating layers of ferrite and cementite, is more prone to corrosion because of its heterogeneous microstructure that facilitates localized rust formation. In industrial applications requiring durability against rust and chemical degradation, ferritic steel is often preferred for enhanced longevity and reduced maintenance costs.

Applications of Ferritic Steel

Ferritic steel is commonly used in automotive exhaust systems and kitchen utensils due to its excellent corrosion resistance and good ductility at high temperatures. Its magnetic properties and weldability make it ideal for manufacturing industrial equipment, structural components, and electromagnetic shielding. Ferritic steel's low carbon content enhances formability, making it preferred for architectural panels and appliances.

Uses of Pearlitic Steel

Pearlitic steel is primarily used in applications requiring high strength and moderate ductility, such as railway tracks, automotive components, and cutting tools. Its fine lamellar structure provides excellent wear resistance and fatigue strength, making it ideal for load-bearing and wear-prone parts. The steel's ability to be heat-treated for enhanced mechanical properties further extends its use in industrial and structural applications.

Weldability and Fabrication

Ferritic steel offers superior weldability compared to pearlitic steel due to its lower carbon content and simpler microstructure, which minimizes cracking and distortion during welding processes. Pearlitic steel, characterized by alternating layers of ferrite and cementite, exhibits higher strength but increased brittleness, making it more challenging to weld and fabricate without specialized techniques. Fabrication of ferritic steel is generally easier and more cost-effective, benefiting applications that demand reliable weld joints and formability.

Cost and Availability

Ferritic steel generally offers lower cost and higher availability due to its simple manufacturing process and abundant chromium content that enhances corrosion resistance. Pearlitic steel, often used in high-strength applications, tends to be more expensive because of its complex microstructure and heat treatment requirements. The widespread use of ferritic steel in automotive and construction industries makes it more accessible in bulk compared to the specialized production of pearlitic steel.

Choosing Between Ferritic and Pearlitic Steel

Ferritic steel offers high corrosion resistance and good ductility, making it suitable for automotive and structural applications where toughness is critical. Pearlitic steel features a lamellar microstructure that provides superior tensile strength and wear resistance, ideal for cutting tools and high-stress mechanical parts. Selecting between ferritic and pearlitic steel depends on the required balance of mechanical properties, corrosion resistance, and application-specific demands.

Ferritic Steel vs Pearlitic Steel Infographic

materialdif.com

materialdif.com