Weathering steel forms a stable rust-like appearance after exposure to weather, which acts as a protective layer against further corrosion, making it ideal for outdoor structures requiring minimal maintenance. Structural steel, often coated or galvanized, provides high strength and flexibility but demands regular protection to prevent rust and deterioration over time. Choosing between weathering steel and structural steel depends on environmental conditions and maintenance capabilities, with weathering steel offering long-term durability in harsh climates without frequent upkeep.

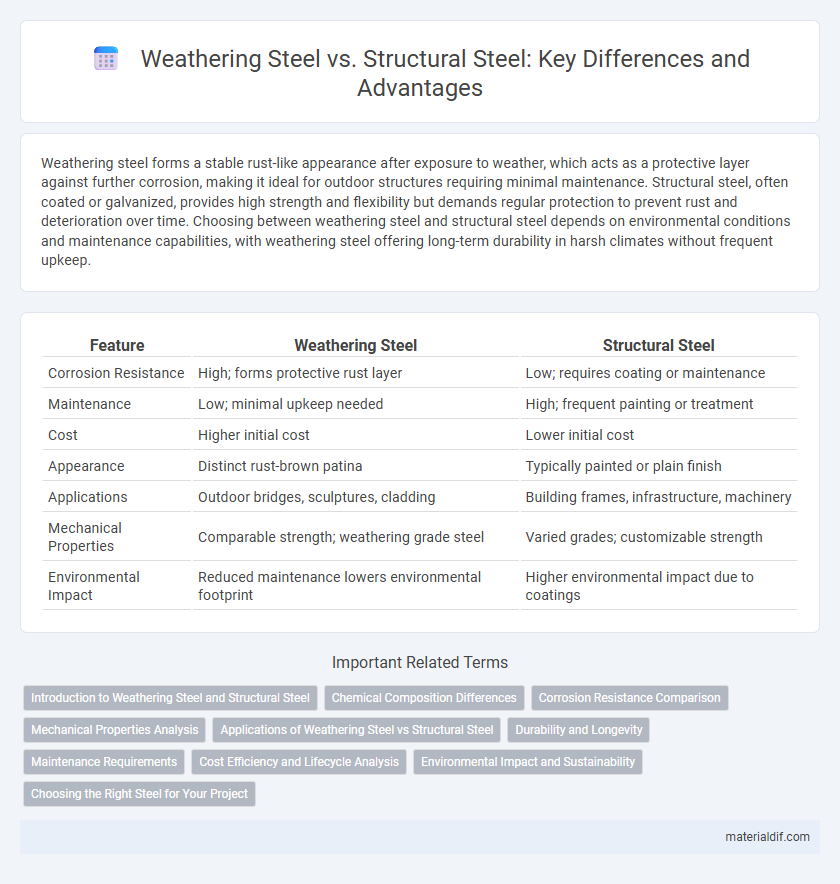

Table of Comparison

| Feature | Weathering Steel | Structural Steel |

|---|---|---|

| Corrosion Resistance | High; forms protective rust layer | Low; requires coating or maintenance |

| Maintenance | Low; minimal upkeep needed | High; frequent painting or treatment |

| Cost | Higher initial cost | Lower initial cost |

| Appearance | Distinct rust-brown patina | Typically painted or plain finish |

| Applications | Outdoor bridges, sculptures, cladding | Building frames, infrastructure, machinery |

| Mechanical Properties | Comparable strength; weathering grade steel | Varied grades; customizable strength |

| Environmental Impact | Reduced maintenance lowers environmental footprint | Higher environmental impact due to coatings |

Introduction to Weathering Steel and Structural Steel

Weathering steel, also known as COR-TEN steel, is a high-strength alloy designed to form a stable rust-like appearance after exposure to weather, which acts as a protective layer against further corrosion. Structural steel, typically carbon steel, provides exceptional strength and durability for construction frameworks but requires protective coatings or treatments to prevent rusting. Weathering steel reduces maintenance costs by eliminating the need for paint, while structural steel offers versatile architectural applications with predictable mechanical properties.

Chemical Composition Differences

Weathering steel contains significant amounts of copper, chromium, nickel, and phosphorus, which enhance its corrosion resistance by forming a stable oxide layer. Structural steel primarily consists of iron with carbon as the main alloying element, and it lacks the specialized alloying elements found in weathering steel. The chemical composition differences result in weathering steel's superior durability in outdoor environments compared to conventional structural steel.

Corrosion Resistance Comparison

Weathering steel contains copper, chromium, nickel, and phosphorus, which form a stable oxide layer that prevents further corrosion, making it highly resistant to atmospheric conditions without requiring paint. Structural steel lacks these alloying elements, making it more susceptible to rust and necessitating protective coatings to enhance corrosion resistance. The superior durability of weathering steel reduces maintenance costs and extends the lifespan of outdoor structures exposed to fluctuating weather.

Mechanical Properties Analysis

Weathering steel exhibits enhanced corrosion resistance and maintains mechanical strength comparable to traditional structural steel, with yield strengths typically ranging from 345 to 552 MPa. Structural steel offers higher ductility and is generally easier to weld, making it ideal for applications requiring significant formability. Mechanical property analysis highlights weathering steel's superior toughness in outdoor environments, reducing maintenance costs without compromising load-bearing capacity.

Applications of Weathering Steel vs Structural Steel

Weathering steel is primarily used in outdoor applications such as bridges, sculptures, and building facades where corrosion resistance and reduced maintenance are crucial. Structural steel is favored in conventional construction projects including commercial buildings, infrastructure, and equipment framing due to its high strength and versatility. Weathering steel's self-protective oxide layer makes it ideal for environments exposed to weather, while structural steel requires protective coatings for similar conditions.

Durability and Longevity

Weathering steel develops a protective rust patina that significantly enhances its durability by resisting corrosion, making it ideal for outdoor structures exposed to harsh weather. Structural steel requires additional coatings or maintenance to prevent rust and ensure longevity in similar environments. The inherent corrosion resistance of weathering steel reduces lifecycle costs and extends the lifespan of infrastructure compared to conventional structural steel.

Maintenance Requirements

Weathering steel requires minimal maintenance due to its corrosion-resistant oxide layer that naturally forms and protects the material, reducing the need for painting or coating over time. Structural steel, by contrast, typically demands regular inspection, surface treatment, and repainting to prevent rust and extend its service life. The reduced maintenance costs and efforts associated with weathering steel make it a preferred choice for outdoor and exposed applications.

Cost Efficiency and Lifecycle Analysis

Weathering steel offers superior cost efficiency over structural steel by reducing maintenance expenses due to its corrosion-resistant properties, which minimize the need for painting and repairs. Lifecycle analysis reveals that weathering steel's durability extends service life, resulting in lower total ownership costs despite a slightly higher initial price. Structural steel requires ongoing protective coatings and frequent maintenance, increasing long-term operational expenses compared to weathering steel.

Environmental Impact and Sustainability

Weathering steel, known for its corrosion resistance through a stable oxide layer, reduces the need for painting and maintenance, significantly lowering environmental impact over its lifecycle compared to traditional structural steel. Structural steel typically requires protective coatings and frequent maintenance, leading to higher emissions and resource use. The sustainability advantage of weathering steel lies in its extended durability and reduced chemical treatments, promoting a more eco-friendly choice for long-term construction projects.

Choosing the Right Steel for Your Project

Weathering steel offers superior corrosion resistance through a stable rust-like patina, reducing maintenance costs and extending the lifespan of outdoor structures. Structural steel provides high strength and versatility, ideal for load-bearing frameworks in buildings and bridges requiring complex shapes and welding. Selecting the right steel depends on environmental exposure, structural requirements, and budget constraints to ensure optimal performance and durability.

Weathering Steel vs Structural Steel Infographic

materialdif.com

materialdif.com