Ferritic steel offers excellent corrosion resistance and good formability, making it ideal for automotive exhaust systems and industrial applications. Duplex steel combines the benefits of ferritic and austenitic steels, providing superior strength and enhanced resistance to stress corrosion cracking in harsh environments. Choosing between ferritic and duplex steel depends on the required mechanical properties and environmental conditions of the specific application.

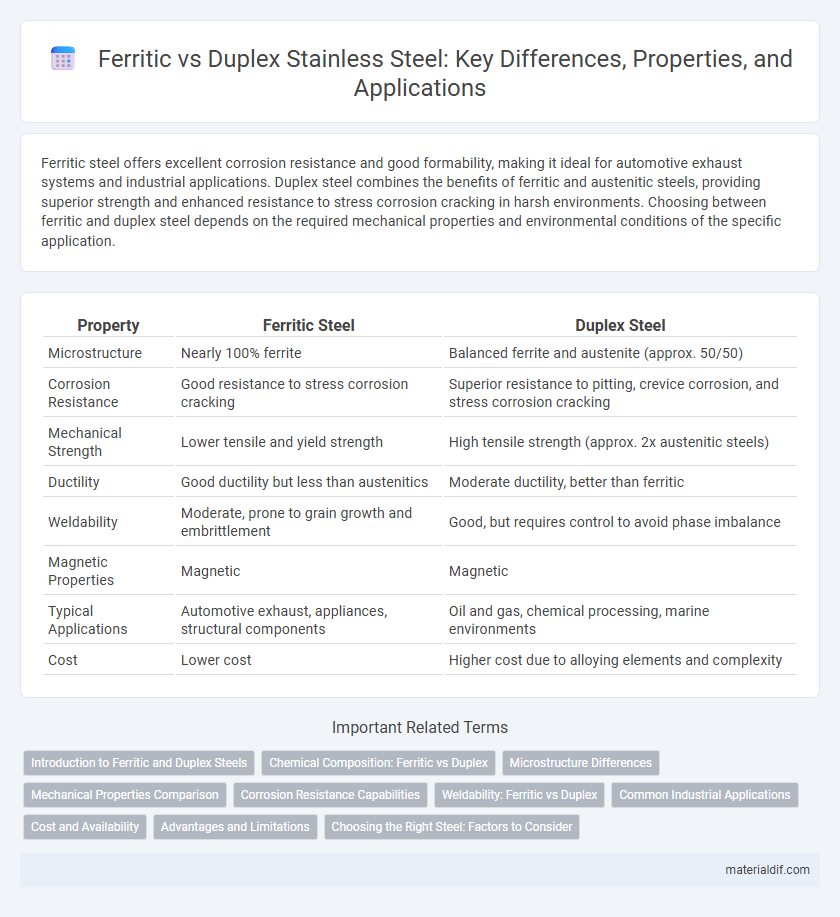

Table of Comparison

| Property | Ferritic Steel | Duplex Steel |

|---|---|---|

| Microstructure | Nearly 100% ferrite | Balanced ferrite and austenite (approx. 50/50) |

| Corrosion Resistance | Good resistance to stress corrosion cracking | Superior resistance to pitting, crevice corrosion, and stress corrosion cracking |

| Mechanical Strength | Lower tensile and yield strength | High tensile strength (approx. 2x austenitic steels) |

| Ductility | Good ductility but less than austenitics | Moderate ductility, better than ferritic |

| Weldability | Moderate, prone to grain growth and embrittlement | Good, but requires control to avoid phase imbalance |

| Magnetic Properties | Magnetic | Magnetic |

| Typical Applications | Automotive exhaust, appliances, structural components | Oil and gas, chemical processing, marine environments |

| Cost | Lower cost | Higher cost due to alloying elements and complexity |

Introduction to Ferritic and Duplex Steels

Ferritic steels are primarily composed of iron with a body-centered cubic (BCC) crystal structure, offering excellent corrosion resistance and good weldability, typically used in automotive and industrial applications. Duplex steels combine ferritic and austenitic microstructures, providing superior strength, toughness, and enhanced resistance to stress corrosion cracking, making them ideal for chemical processing and marine environments. Both steel types optimize performance through distinct grain structures and alloy compositions tailored to specific mechanical and corrosion resistance requirements.

Chemical Composition: Ferritic vs Duplex

Ferritic stainless steels typically contain 10.5-30% chromium with very low carbon content, and lack significant amounts of nickel, making them cost-effective and magnetic. Duplex stainless steels consist of approximately 20-30% chromium, 4-8% nickel, and 1.5-5% molybdenum, offering a balanced microstructure of austenite and ferrite phases that enhances strength and corrosion resistance. The higher nickel and molybdenum content in duplex grades improves resistance to chloride-induced stress corrosion cracking compared to ferritic steels.

Microstructure Differences

Ferritic steels feature a body-centered cubic (BCC) microstructure with primarily ferrite grains, providing excellent corrosion resistance and magnetic properties. Duplex steels combine a balanced microstructure of approximately 50% ferrite and 50% austenite, enhancing strength and toughness compared to purely ferritic steels. The dual-phase nature of duplex steels results in superior resistance to stress corrosion cracking and better mechanical performance under harsh conditions.

Mechanical Properties Comparison

Ferritic steels exhibit excellent corrosion resistance and good ductility but have lower strength and toughness compared to duplex steels. Duplex steels combine austenitic and ferritic phases, offering superior tensile strength, enhanced toughness, and improved resistance to stress corrosion cracking. The mechanical properties of duplex steel typically include yield strength around 450-550 MPa and tensile strength up to 750-900 MPa, surpassing the approximately 250-450 MPa yield strength and 450-600 MPa tensile strength of ferritic grades.

Corrosion Resistance Capabilities

Ferritic steels exhibit moderate corrosion resistance due to their high chromium content, providing good resistance to stress corrosion cracking in mildly corrosive environments. Duplex steels combine a balanced microstructure of ferrite and austenite, offering superior corrosion resistance, especially in chloride-rich environments and against pitting and crevice corrosion. The enhanced corrosion resistance of duplex steel makes it ideal for aggressive applications such as marine and chemical processing industries.

Weldability: Ferritic vs Duplex

Ferritic steel offers moderate weldability with a tendency for grain growth and reduced toughness in heat-affected zones, requiring controlled cooling to prevent brittleness. Duplex steel exhibits superior weldability due to its balanced austenitic-ferritic microstructure, resulting in enhanced resistance to cracking and improved mechanical properties post-welding. Proper welding techniques like controlled heat input and interpass temperature regulation are essential to maintain duplex steel's microstructural integrity and corrosion resistance.

Common Industrial Applications

Ferritic stainless steels, known for their corrosion resistance and good ductility, are commonly used in automotive exhaust systems, kitchen appliances, and industrial equipment. Duplex stainless steels combine the strength of martensitic with the corrosion resistance of austenitic steels, making them ideal for chemical processing plants, offshore oil and gas platforms, and desalination plants. Both types offer specific advantages tailored to environments requiring durability and resistance to stress corrosion cracking.

Cost and Availability

Ferritic steels typically offer lower cost and higher availability compared to duplex steels due to simpler alloy compositions and widespread production. Duplex steels, while more expensive and less readily available, provide superior corrosion resistance and strength by combining austenitic and ferritic microstructures. Cost-driven projects often favor ferritic grades, especially where moderate performance suffices, whereas duplex steels are selected for demanding environments despite higher prices.

Advantages and Limitations

Ferritic steel offers excellent corrosion resistance and good ductility, making it ideal for automotive and architectural applications, but it has lower strength and toughness compared to duplex steel. Duplex steel combines the benefits of ferritic and austenitic steels, providing superior strength, higher corrosion resistance, and better weldability, which is advantageous for chemical and marine environments. However, duplex steel's limitations include higher cost and susceptibility to embrittlement at elevated temperatures, limiting its use in high-heat applications.

Choosing the Right Steel: Factors to Consider

Selecting between ferritic and duplex steel depends on factors such as corrosion resistance, mechanical strength, and application environment. Ferritic steel offers excellent resistance to stress corrosion cracking and is cost-effective for moderate strength needs, while duplex steel combines austenitic and ferritic properties, providing higher strength and superior resistance to chloride-induced corrosion. Consider the operational temperature, chemical exposure, and mechanical load requirements to determine the optimal steel grade for your project.

Ferritic vs Duplex Infographic

materialdif.com

materialdif.com