Spring steel offers exceptional elasticity and high yield strength, making it ideal for applications requiring repeated flexing without permanent deformation. Structural steel provides superior load-bearing capacity and durability, commonly used in construction and infrastructure projects that demand strength and stability. Choosing between spring steel and structural steel depends on whether flexibility or structural integrity is the priority for the specific steel pet application.

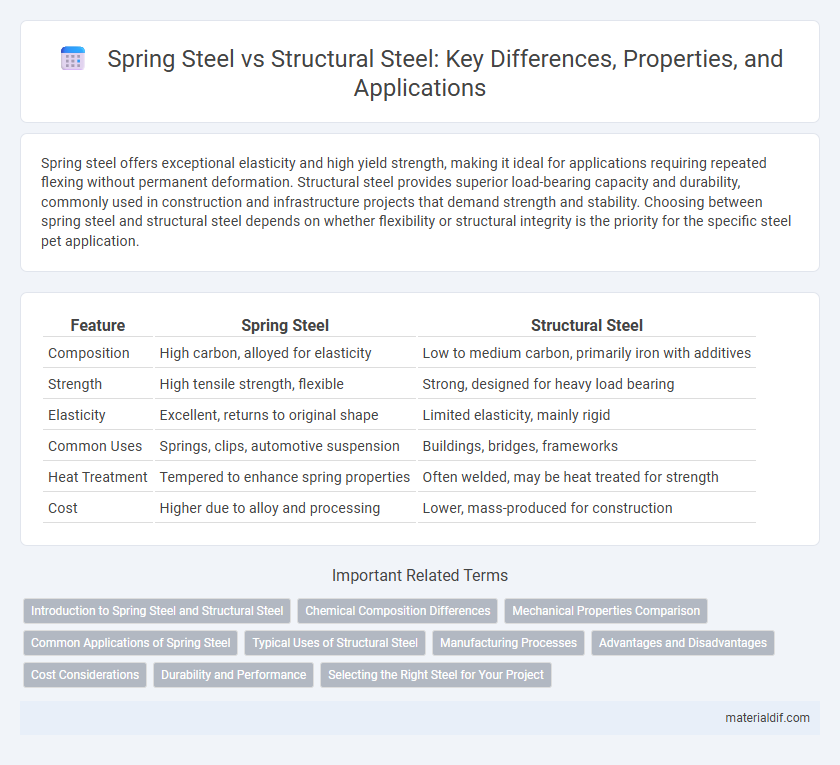

Table of Comparison

| Feature | Spring Steel | Structural Steel |

|---|---|---|

| Composition | High carbon, alloyed for elasticity | Low to medium carbon, primarily iron with additives |

| Strength | High tensile strength, flexible | Strong, designed for heavy load bearing |

| Elasticity | Excellent, returns to original shape | Limited elasticity, mainly rigid |

| Common Uses | Springs, clips, automotive suspension | Buildings, bridges, frameworks |

| Heat Treatment | Tempered to enhance spring properties | Often welded, may be heat treated for strength |

| Cost | Higher due to alloy and processing | Lower, mass-produced for construction |

Introduction to Spring Steel and Structural Steel

Spring steel is a high-carbon steel known for its exceptional elasticity and ability to return to its original shape after deformation, making it ideal for applications requiring flexibility and fatigue resistance such as springs, clips, and fasteners. Structural steel, typically composed of carbon and manganese, is engineered for strength, durability, and load-bearing capacity, widely used in construction for frameworks, bridges, and buildings. Understanding the distinct mechanical properties and compositional differences of spring steel and structural steel is essential for selecting the appropriate material in industrial and architectural applications.

Chemical Composition Differences

Spring steel typically contains higher amounts of carbon, usually between 0.5% and 1.0%, along with manganese and silicon to enhance its elasticity and tensile strength. Structural steel, by contrast, has a lower carbon content, generally below 0.3%, with added elements such as copper, nickel, or chromium to improve weldability, toughness, and corrosion resistance. These chemical composition differences directly influence the mechanical properties and applications of spring steel and structural steel in engineering and construction.

Mechanical Properties Comparison

Spring steel exhibits superior tensile strength and elasticity, making it ideal for applications requiring high fatigue resistance and flexibility. Structural steel offers higher yield strength and better weldability, suitable for load-bearing frameworks and construction. Comparing their mechanical properties, spring steel excels in resilience under repeated stress, while structural steel provides greater rigidity and structural support.

Common Applications of Spring Steel

Spring steel is commonly used in applications requiring high elasticity and fatigue resistance, such as automotive suspension components, springs, and clips. Its ability to return to its original shape after deformation makes it ideal for manufacturing tools, saw blades, and fasteners. Structural steel, by contrast, is primarily utilized in construction and infrastructure for load-bearing frameworks and support beams.

Typical Uses of Structural Steel

Structural steel is primarily used in construction projects such as bridges, buildings, and industrial warehouses due to its high strength, durability, and load-bearing capacity. Its versatility allows it to form frameworks, support columns, beams, and reinforcement structures essential for large-scale infrastructure. Unlike spring steel, which is designed for flexibility and resilience in applications like springs and automotive components, structural steel emphasizes stability and rigidity for lasting structural integrity.

Manufacturing Processes

Spring steel undergoes heat treatment processes such as quenching and tempering to enhance its elasticity and tensile strength, making it ideal for components subjected to repeated stress. Structural steel is primarily fabricated through hot rolling or cold forming processes to achieve the desired shape and strength for construction frameworks. Both steels require precise control of alloy composition, but spring steel's manufacturing emphasizes hardness and flexibility, whereas structural steel focuses on load-bearing capacity and weldability.

Advantages and Disadvantages

Spring steel offers exceptional elasticity and fatigue resistance, making it ideal for applications requiring repeated bending, such as springs and clips. Structural steel provides superior strength and durability for construction purposes but lacks the high elasticity necessary for dynamic loads. While spring steel can endure cyclic stress without permanent deformation, structural steel is more affordable and easier to weld, limiting its use in flexible components.

Cost Considerations

Spring steel generally incurs a higher cost than structural steel due to its alloy composition and heat treatment processes that enhance elasticity and strength. Structural steel is more economical, favored for large-scale construction projects where cost efficiency and load-bearing capacity are critical. Budget constraints and specific performance requirements often determine the choice between these two steel types.

Durability and Performance

Spring steel exhibits exceptional durability and performance due to its high yield strength and ability to return to its original shape after significant deformation, making it ideal for applications requiring flexibility and fatigue resistance. Structural steel, while also durable, prioritizes load-bearing capacity and weldability, providing robust performance in construction and infrastructure projects without the same level of elasticity. The distinct metallurgical properties of spring steel contribute to superior fatigue resistance, whereas structural steel's strength and toughness ensure long-term structural integrity under static and dynamic loads.

Selecting the Right Steel for Your Project

Spring steel offers exceptional elasticity and fatigue resistance, making it ideal for applications requiring high durability under repeated stress, such as springs and automotive components. Structural steel provides superior strength and load-bearing capacity, suited for construction projects like buildings, bridges, and infrastructure frameworks. Choosing the right steel depends on balancing mechanical properties with project demands for flexibility versus structural integrity.

Spring steel vs Structural steel Infographic

materialdif.com

materialdif.com