Mild steel offers excellent ductility and ease of welding, making it ideal for construction and manufacturing applications requiring flexibility and affordability. High-tensile steel provides superior strength and resistance to deformation, suitable for heavy-duty structural components and automotive parts that demand high load-bearing capacity. Choosing between mild steel and high-tensile steel depends on the balance needed between strength, weight, and cost-efficiency for specific engineering projects.

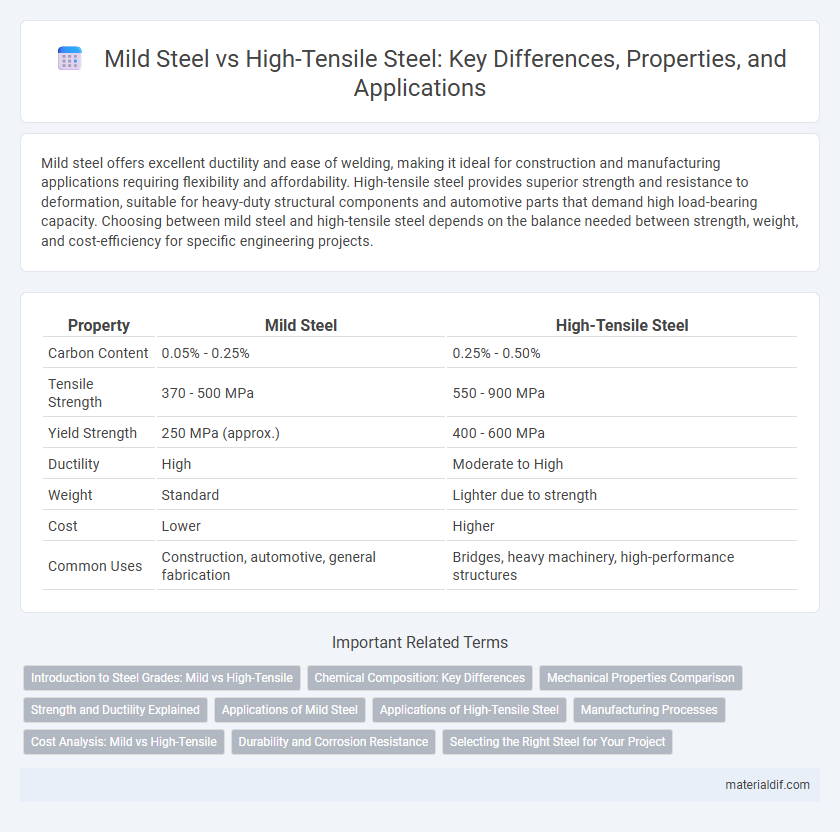

Table of Comparison

| Property | Mild Steel | High-Tensile Steel |

|---|---|---|

| Carbon Content | 0.05% - 0.25% | 0.25% - 0.50% |

| Tensile Strength | 370 - 500 MPa | 550 - 900 MPa |

| Yield Strength | 250 MPa (approx.) | 400 - 600 MPa |

| Ductility | High | Moderate to High |

| Weight | Standard | Lighter due to strength |

| Cost | Lower | Higher |

| Common Uses | Construction, automotive, general fabrication | Bridges, heavy machinery, high-performance structures |

Introduction to Steel Grades: Mild vs High-Tensile

Mild steel, characterized by low carbon content (typically 0.05-0.25%), offers excellent ductility and weldability, making it suitable for general construction and automotive applications. High-tensile steel contains higher carbon and alloying elements, providing significantly greater strength and hardness, ideal for structural components requiring enhanced load-bearing capacity. The distinct mechanical properties and chemical compositions of these steel grades determine their optimal uses in engineering and manufacturing sectors.

Chemical Composition: Key Differences

Mild steel primarily contains 0.05-0.25% carbon, offering ductility and weldability, while high-tensile steel features a higher carbon content ranging from 0.25-0.55%, enhancing strength and hardness. The presence of alloying elements like manganese (0.3-1.5% in high-tensile steel) and traces of silicon, sulfur, and phosphorus affects mechanical properties significantly. These chemical composition variations result in mild steel being more malleable and high-tensile steel exhibiting superior load-bearing capacity for structural applications.

Mechanical Properties Comparison

Mild steel typically exhibits lower tensile strength, ranging from 250 to 400 MPa, coupled with higher ductility and better weldability, making it suitable for general construction and fabrication. High-tensile steel offers a significantly greater tensile strength, often exceeding 550 MPa, with improved yield strength and enhanced fatigue resistance, which are critical for demanding structural applications and automotive components. The hardness and impact toughness of high-tensile steel surpass those of mild steel, providing superior performance under high stress and dynamic loading conditions.

Strength and Ductility Explained

Mild steel offers moderate strength and high ductility, making it ideal for applications requiring extensive shaping and welding. High-tensile steel provides significantly greater strength due to its alloying elements and heat treatment but exhibits lower ductility, limiting its ability to deform without fracture. The balance between strength and ductility determines their suitability in construction, automotive, and manufacturing industries, where performance under stress and flexibility are critical factors.

Applications of Mild Steel

Mild steel is extensively used in construction due to its excellent weldability and ductility, making it ideal for structural components, beams, and reinforcements. It also finds widespread application in manufacturing automotive body panels, machinery parts, and pipelines where moderate strength and formability are crucial. Compared to high-tensile steel, mild steel is preferred for applications that require ease of fabrication and cost-effectiveness without the need for extreme tensile strength.

Applications of High-Tensile Steel

High-tensile steel is widely used in automotive manufacturing due to its superior strength-to-weight ratio, which improves fuel efficiency and crashworthiness. It is also essential in construction for structural components like bridges and skyscraper frameworks, where enhanced load-bearing capacity and durability are critical. In the shipbuilding industry, high-tensile steel provides resistance to harsh marine environments while maintaining structural integrity under dynamic stresses.

Manufacturing Processes

Mild steel is produced through a basic oxygen furnace or electric arc furnace method, where carbon content is controlled to be low, enhancing ductility and weldability during manufacturing. High-tensile steel undergoes additional alloying with elements like manganese, nickel, and chromium, followed by heat treatment processes such as quenching and tempering to achieve superior strength and toughness. The manufacturing processes for high-tensile steel involve precise control of cooling rates and mechanical working to optimize grain structure for enhanced performance in demanding applications.

Cost Analysis: Mild vs High-Tensile

Mild steel typically costs less per ton than high-tensile steel due to its simpler production process and lower alloy content. High-tensile steel demands higher manufacturing expenses but offers superior strength, potentially reducing material usage and labor costs in structural applications. Evaluating total project expenses, including material efficiency and long-term durability, is crucial for cost-effective steel selection.

Durability and Corrosion Resistance

Mild steel offers moderate durability with good machinability but tends to corrode more easily when exposed to moisture and environmental elements due to its lower carbon content. High-tensile steel provides superior durability and enhanced resistance to wear and deformation, making it ideal for heavy-load applications, while its alloying elements improve corrosion resistance compared to mild steel. Protective coatings and treatments are often required for both steels to prevent rust, but high-tensile steel typically maintains structural integrity longer under harsh conditions.

Selecting the Right Steel for Your Project

Mild steel offers excellent ductility and weldability, making it ideal for general construction and structural applications where flexibility and ease of fabrication are priorities. High-tensile steel provides superior strength and durability, suitable for heavy-duty projects requiring enhanced load-bearing capacity and resistance to deformation. Selecting the right steel depends on balancing performance requirements, weight considerations, and cost-effectiveness for your specific project needs.

Mild steel vs High-tensile steel Infographic

materialdif.com

materialdif.com