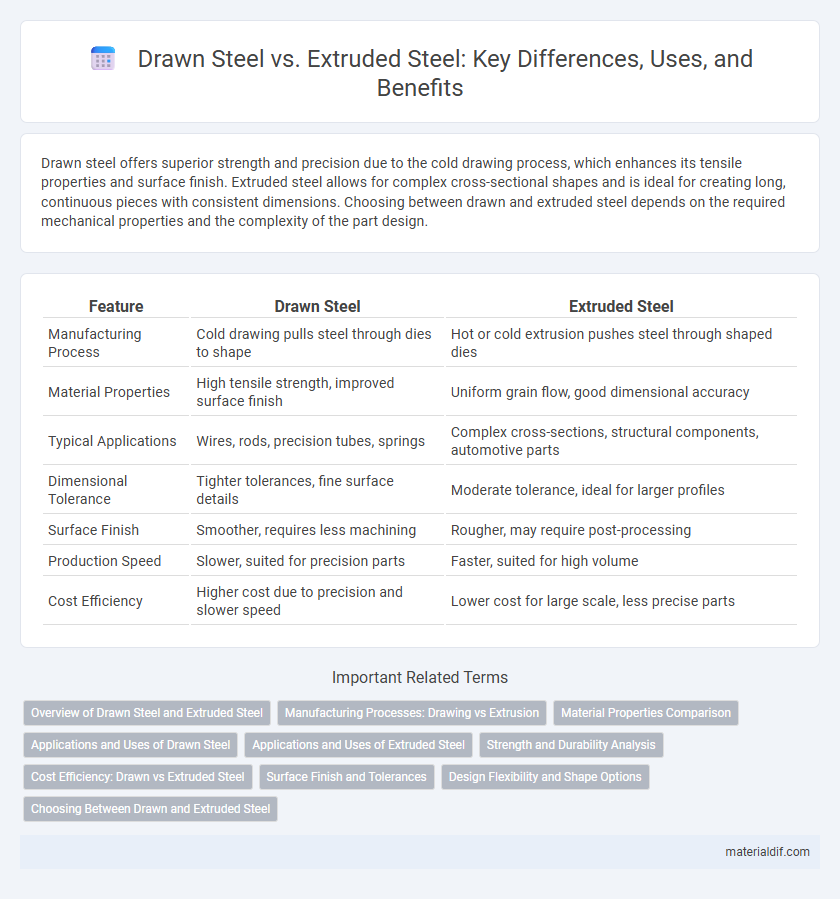

Drawn steel offers superior strength and precision due to the cold drawing process, which enhances its tensile properties and surface finish. Extruded steel allows for complex cross-sectional shapes and is ideal for creating long, continuous pieces with consistent dimensions. Choosing between drawn and extruded steel depends on the required mechanical properties and the complexity of the part design.

Table of Comparison

| Feature | Drawn Steel | Extruded Steel |

|---|---|---|

| Manufacturing Process | Cold drawing pulls steel through dies to shape | Hot or cold extrusion pushes steel through shaped dies |

| Material Properties | High tensile strength, improved surface finish | Uniform grain flow, good dimensional accuracy |

| Typical Applications | Wires, rods, precision tubes, springs | Complex cross-sections, structural components, automotive parts |

| Dimensional Tolerance | Tighter tolerances, fine surface details | Moderate tolerance, ideal for larger profiles |

| Surface Finish | Smoother, requires less machining | Rougher, may require post-processing |

| Production Speed | Slower, suited for precision parts | Faster, suited for high volume |

| Cost Efficiency | Higher cost due to precision and slower speed | Lower cost for large scale, less precise parts |

Overview of Drawn Steel and Extruded Steel

Drawn steel is produced by pulling a steel billet through a die to reduce its diameter, resulting in improved tensile strength and surface finish ideal for precision components. Extruded steel involves forcing heated steel through a shaped die to create longer lengths with uniform cross-sections, commonly used in structural applications like beams and rails. Both processes enhance steel properties but serve different manufacturing needs, with drawn steel emphasizing dimensional accuracy and extruded steel offering versatile profiles.

Manufacturing Processes: Drawing vs Extrusion

Drawn steel undergoes a cold working process where the metal is pulled through a die to reduce its diameter and shape it with high dimensional accuracy and improved surface finish. Extruded steel involves forcing heated billet through a shaped die to create continuous profiles with complex cross-sections and enhanced mechanical properties due to grain flow alignment. The drawing process emphasizes precision and surface quality, while extrusion allows for intricate shapes and greater material versatility.

Material Properties Comparison

Drawn steel exhibits superior tensile strength and enhanced surface finish due to the cold working process that aligns its grain structure, while extruded steel typically offers greater dimensional uniformity and complexity in cross-sectional shapes because it is shaped through plastic deformation under high pressure. The mechanical properties of drawn steel include higher hardness and improved fatigue resistance compared to extruded steel, which is more ductile and often easier to machine post-processing. Material selection depends on the application requirements, with drawn steel favored for components needing high strength and surface quality, whereas extruded steel suits designs requiring precise, intricate profiles.

Applications and Uses of Drawn Steel

Drawn steel is predominantly used in applications requiring high strength and precise dimensions, including automotive components, springs, and fasteners due to its enhanced tensile properties and uniformity. In contrast to extruded steel, drawn steel excels in producing wire, rods, and tubes integral to the manufacturing of cables, musical instruments, and medical devices. Its ability to withstand significant mechanical stress makes it ideal for structural reinforcements and industrial machinery parts.

Applications and Uses of Extruded Steel

Extruded steel is widely used in applications requiring complex cross-sectional shapes such as structural components, automotive frames, and machinery parts due to its ability to create uniform, precise profiles with excellent mechanical properties. Its versatility makes it ideal for architectural frameworks, aerospace components, and transportation equipment where strength-to-weight ratio and design flexibility are critical. Unlike drawn steel, which is often used for wire and tubing, extruded steel excels in manufacturing large, load-bearing structures and custom-designed industrial parts.

Strength and Durability Analysis

Drawn steel exhibits superior tensile strength and enhanced fatigue resistance due to its cold working process, which aligns the grain structure and reduces internal defects. Extruded steel, while offering complex shapes with consistent cross-sectional profiles, may have slightly lower strength and durability because of the elevated temperatures involved in extrusion that can coarsen the microstructure. Strength and durability in applications demanding high wear resistance favor drawn steel, especially in automotive and aerospace components where mechanical performance is critical.

Cost Efficiency: Drawn vs Extruded Steel

Drawn steel typically offers higher cost efficiency in large-scale production due to lower tooling expenses and faster processing speeds compared to extruded steel. Extruded steel, while providing superior dimensional accuracy and complex cross-sectional shapes, often incurs higher energy consumption and equipment costs, impacting overall expense. Selecting drawn steel optimizes material usage and reduces manufacturing overhead, making it more economical for standard profiles and volume-driven applications.

Surface Finish and Tolerances

Drawn steel features a smooth surface finish due to the metal being pulled through dies, resulting in precise dimensional tolerances ideal for applications requiring uniformity and high-quality aesthetics. Extruded steel, created by forcing the metal through a shaped opening, often exhibits a slightly rougher surface with more variation in tolerances, suitable for complex cross-sectional profiles but less critical surface requirements. Tighter tolerances and finer finishes in drawn steel make it preferred for precision machinery parts, whereas extruded steel excels in structural components with intricate shapes.

Design Flexibility and Shape Options

Drawn steel offers superior design flexibility and a wider range of complex shape options due to its manufacturing process, allowing for precise control over thickness and cross-sectional profiles. Extruded steel, while effective for creating uniform and simpler shapes, is limited by die design constraints, making it less adaptable for intricate geometries. Industries demanding customized steel components often prefer drawn steel for its versatility in achieving detailed and varied shapes.

Choosing Between Drawn and Extruded Steel

Choosing between drawn and extruded steel depends on the desired mechanical properties and dimensional precision. Drawn steel offers superior tensile strength and surface finish due to the cold working process, making it ideal for applications requiring high durability and tight tolerances. Extruded steel provides better flexibility in cross-sectional shapes and is suited for complex profiles, often used in structural components where shape versatility is crucial.

Drawn Steel vs Extruded Steel Infographic

materialdif.com

materialdif.com