Normalized steel undergoes controlled heating and air cooling to refine its grain structure, resulting in improved toughness and uniform mechanical properties. Quenched steel is rapidly cooled from high temperature, producing a harder and stronger microstructure but often requiring tempering to reduce brittleness. Choosing between normalized and quenched steel depends on the desired balance between strength, hardness, and ductility for specific applications.

Table of Comparison

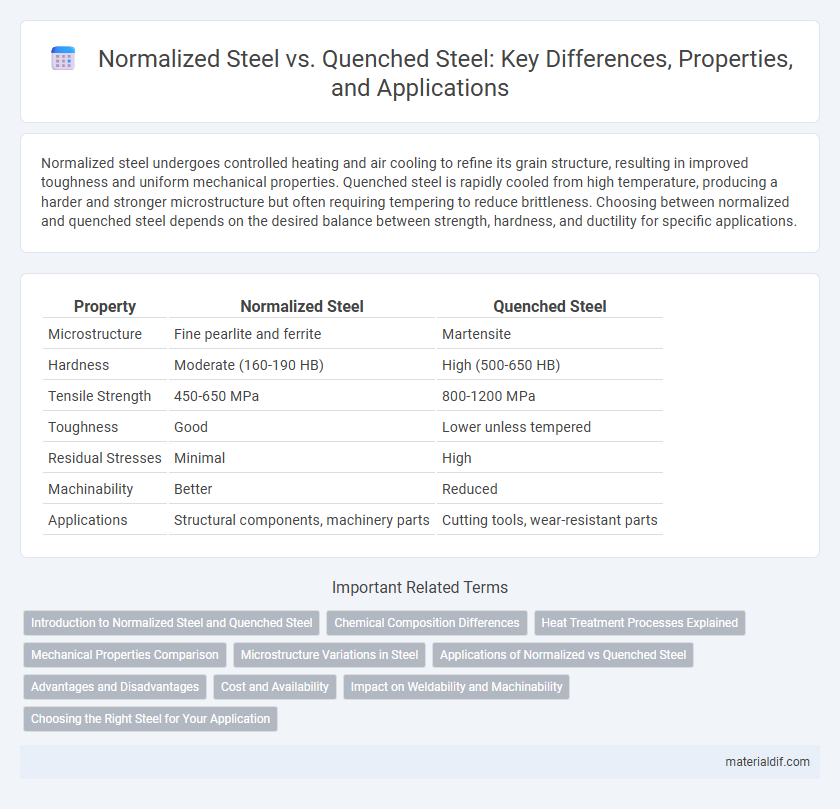

| Property | Normalized Steel | Quenched Steel |

|---|---|---|

| Microstructure | Fine pearlite and ferrite | Martensite |

| Hardness | Moderate (160-190 HB) | High (500-650 HB) |

| Tensile Strength | 450-650 MPa | 800-1200 MPa |

| Toughness | Good | Lower unless tempered |

| Residual Stresses | Minimal | High |

| Machinability | Better | Reduced |

| Applications | Structural components, machinery parts | Cutting tools, wear-resistant parts |

Introduction to Normalized Steel and Quenched Steel

Normalized steel is a heat-treated steel that is heated to a temperature above its critical range, then air-cooled to refine grain structure and improve uniformity in mechanical properties. Quenched steel undergoes rapid cooling, usually in water or oil, from a high temperature to increase hardness and strength by transforming the microstructure into martensite. Both processes enhance steel's performance but target different combinations of strength, toughness, and ductility.

Chemical Composition Differences

Normalized steel typically features a balanced carbon content ranging from 0.20% to 0.50% with controlled levels of manganese (0.50% to 1.00%) and minimal amounts of other alloying elements, promoting uniform grain structure and improved toughness. In contrast, quenched steel often contains higher carbon content, sometimes exceeding 0.60%, and may include alloying elements like chromium, molybdenum, or nickel to enhance hardenability and strength after rapid cooling. The variation in chemical composition between normalized and quenched steels directly influences their mechanical properties, with normalized steel favoring ductility and toughness, while quenched steel is optimized for hardness and tensile strength.

Heat Treatment Processes Explained

Normalized steel undergoes heating above its critical temperature followed by air cooling, which refines the grain structure and enhances toughness and uniformity. Quenched steel is rapidly cooled from high temperatures using water, oil, or polymer solutions to increase hardness and strength by forming martensite. Both heat treatment processes manipulate cooling rates to optimize mechanical properties for specific industrial applications.

Mechanical Properties Comparison

Normalized steel offers improved toughness and ductility due to its refined grain structure, making it suitable for applications requiring moderate strength and good machinability. Quenched steel, subjected to rapid cooling, achieves higher hardness and tensile strength but often exhibits reduced ductility and increased brittleness. The choice between normalized and quenched steel depends on the balance needed between strength, hardness, and toughness for specific engineering requirements.

Microstructure Variations in Steel

Normalized steel features a fine pearlitic-ferrite microstructure achieved through air cooling from the austenitizing temperature, enhancing uniformity and toughness. Quenched steel exhibits a predominantly martensitic microstructure formed by rapid cooling, which significantly increases hardness and strength but reduces ductility. These microstructure variations directly influence mechanical properties, making normalized steel preferable for balanced strength and toughness, while quenched steel suits applications requiring high hardness.

Applications of Normalized vs Quenched Steel

Normalized steel is commonly used in structural applications such as bridges and buildings where uniform mechanical properties and improved toughness are essential. Quenched steel finds extensive use in high-strength applications like automotive components, heavy machinery, and cutting tools requiring enhanced hardness and wear resistance. The choice between normalized and quenched steel depends on balancing ductility, tensile strength, and toughness for specific engineering requirements.

Advantages and Disadvantages

Normalized steel offers improved toughness and machinability due to its refined grain structure, making it suitable for general engineering applications, while quenched steel provides superior hardness and wear resistance because of its martensitic microstructure, ideal for high-strength components. However, normalized steel has lower strength and wear resistance compared to quenched steel, which can be brittle and prone to cracking without proper tempering. The choice between normalized and quenched steel depends on balancing the desired mechanical properties with application-specific requirements like durability and ease of fabrication.

Cost and Availability

Normalized steel undergoes controlled heating and air cooling, offering a balance of strength and ductility at a lower manufacturing cost, making it widely available for general construction and automotive applications. Quenched steel, subjected to rapid cooling in water or oil, possesses higher hardness and strength but incurs greater processing expenses and limited availability due to more complex heat treatment requirements. Budget-sensitive projects with standard performance needs often favor normalized steel, while quenched steel is chosen for specialized uses demanding superior mechanical properties despite its higher cost and reduced supply.

Impact on Weldability and Machinability

Normalized steel exhibits improved weldability due to its uniform grain structure, reducing the risk of cracking during welding processes. Quenched steel, with its harder and more brittle microstructure, often presents challenges in machinability, requiring specialized tooling and slower cutting speeds. The difference in thermal treatment significantly influences the steel's mechanical properties, directly impacting its performance in welding and machining applications.

Choosing the Right Steel for Your Application

Normalized steel undergoes controlled cooling in air, resulting in a uniform grain structure that enhances toughness and machinability, making it ideal for general structural applications. Quenched steel is rapidly cooled in water or oil, producing a harder and stronger material with increased wear resistance, suitable for high-stress components like gears and shafts. Selecting the right steel depends on balancing mechanical properties such as hardness, toughness, and ductility against the specific requirements of the application environment.

Normalized Steel vs Quenched Steel Infographic

materialdif.com

materialdif.com