HSLA steel offers improved mechanical properties such as increased strength and toughness through microalloying elements while maintaining weldability and formability, making it ideal for structural applications. Ultra-high-strength steel (UHSS) provides significantly greater tensile strength and hardness, often through advanced heat treatment processes, enabling weight reduction in automotive and aerospace components without compromising safety. Selecting between HSLA and UHSS depends on balancing factors like cost, manufacturability, and specific performance requirements in demanding environments.

Table of Comparison

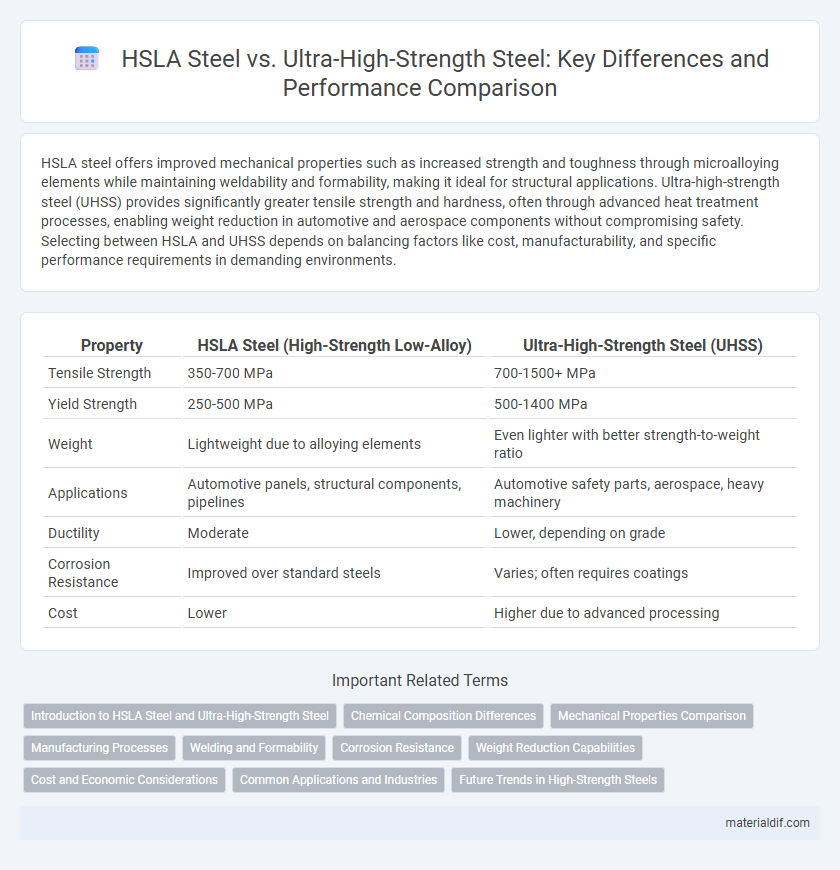

| Property | HSLA Steel (High-Strength Low-Alloy) | Ultra-High-Strength Steel (UHSS) |

|---|---|---|

| Tensile Strength | 350-700 MPa | 700-1500+ MPa |

| Yield Strength | 250-500 MPa | 500-1400 MPa |

| Weight | Lightweight due to alloying elements | Even lighter with better strength-to-weight ratio |

| Applications | Automotive panels, structural components, pipelines | Automotive safety parts, aerospace, heavy machinery |

| Ductility | Moderate | Lower, depending on grade |

| Corrosion Resistance | Improved over standard steels | Varies; often requires coatings |

| Cost | Lower | Higher due to advanced processing |

Introduction to HSLA Steel and Ultra-High-Strength Steel

HSLA steel, or High-Strength Low-Alloy steel, offers enhanced strength and corrosion resistance through microalloying elements like vanadium and niobium, making it ideal for automotive and structural applications. Ultra-High-Strength Steel (UHSS) surpasses HSLA in tensile strength, often exceeding 1000 MPa, achieved through advanced heat treatment and complex alloying, used primarily in safety-critical components. Both steels contribute to weight reduction and performance improvement but differ significantly in mechanical properties and manufacturing processes.

Chemical Composition Differences

HSLA steel contains lower carbon content, typically less than 0.2%, with added microalloying elements such as niobium, vanadium, and titanium to enhance strength and toughness while maintaining weldability. Ultra-high-strength steel (UHSS) features higher carbon and alloying elements including manganese, chromium, molybdenum, and boron, resulting in superior tensile strength often exceeding 1000 MPa. The chemical composition variations directly influence mechanical properties, corrosion resistance, and applications in automotive and structural industries.

Mechanical Properties Comparison

HSLA steel offers tensile strengths typically ranging from 350 to 700 MPa, featuring superior toughness and weldability, making it ideal for structural applications requiring a balance of strength and ductility. Ultra-high-strength steel (UHSS) surpasses this with tensile strengths exceeding 900 MPa and up to 1500 MPa, providing exceptional strength and hardness but often with reduced ductility compared to HSLA steels. The choice between HSLA and UHSS depends on application-specific requirements for mechanical strength, weight reduction, and formability in industries such as automotive and construction.

Manufacturing Processes

HSLA steel manufacturing involves controlled rolling and microalloying with elements like niobium, vanadium, or titanium to improve grain refinement and strength without excessive alloying. Ultra-high-strength steel (UHSS) undergoes precise heat treatment processes such as quenching and tempering or martensitic transformation to achieve superior tensile strength beyond HSLA grades. The advanced processing techniques in UHSS result in higher hardness and toughness, making it suitable for critical automotive and aerospace structural components.

Welding and Formability

HSLA steel offers superior weldability due to its lower carbon content and refined microstructure, making it easier to achieve strong, crack-resistant welds compared to ultra-high-strength steel (UHSS). Ultra-high-strength steel features higher tensile strength but reduced formability and increased sensitivity to heat during welding, often requiring specialized techniques to avoid brittle weld zones. Formability in HSLA steel is generally better, allowing more complex shapes without cracking, whereas UHSS demands precise control during forming and welding to maintain structural integrity.

Corrosion Resistance

HSLA steel offers moderate corrosion resistance due to its controlled alloying elements like copper, chromium, and nickel, making it suitable for structural applications with exposure to mild environments. Ultra-high-strength steel, specifically engineered with advanced coatings and alloy compositions, provides enhanced corrosion resistance critical for automotive and aerospace components subjected to harsh conditions. Corrosion resistance in both steels is influenced by alloying balance and surface treatments, but ultra-high-strength steel generally outperforms HSLA steel in aggressive environments.

Weight Reduction Capabilities

HSLA steel offers moderate weight reduction through improved strength-to-weight ratios compared to conventional carbon steel, making it suitable for structural applications where durability and weldability are crucial. Ultra-High-Strength Steel (UHSS) provides superior weight reduction benefits by enabling thinner components without sacrificing mechanical performance, ideal for automotive and aerospace industries focused on fuel efficiency. The advanced metallurgical properties of UHSS allow for more aggressive design optimizations, significantly decreasing overall vehicle weight while maintaining safety and rigidity standards.

Cost and Economic Considerations

HSLA steel generally offers a cost-effective solution with lower production and processing expenses compared to ultra-high-strength steel, making it ideal for applications requiring moderate strength and good weldability. Ultra-high-strength steel, while providing superior mechanical properties and weight reduction benefits, incurs higher raw material costs and more complex manufacturing processes. The choice between HSLA and ultra-high-strength steel hinges on balancing upfront material costs against long-term performance gains and lifecycle savings in industries such as automotive and construction.

Common Applications and Industries

HSLA steel is widely used in automotive manufacturing, construction, and heavy machinery due to its excellent strength-to-weight ratio and corrosion resistance. Ultra-high-strength steel finds common applications in aerospace, military armor, and high-performance automotive components where superior tensile strength and impact resistance are critical. Both steels serve industries requiring durability and weight savings but differ in strength thresholds and specialized uses.

Future Trends in High-Strength Steels

Future trends in high-strength steels focus on enhancing strength-to-weight ratios and improving weldability to meet the demands of automotive and aerospace industries. HSLA steel continues evolving with microalloying and thermo-mechanical processing innovations to boost toughness and corrosion resistance. Ultra-high-strength steel advances prioritize nanostructured alloys and gradient architectures to achieve superior mechanical performance and energy absorption in crash-resistant structures.

HSLA Steel vs Ultra-High-Strength Steel Infographic

materialdif.com

materialdif.com