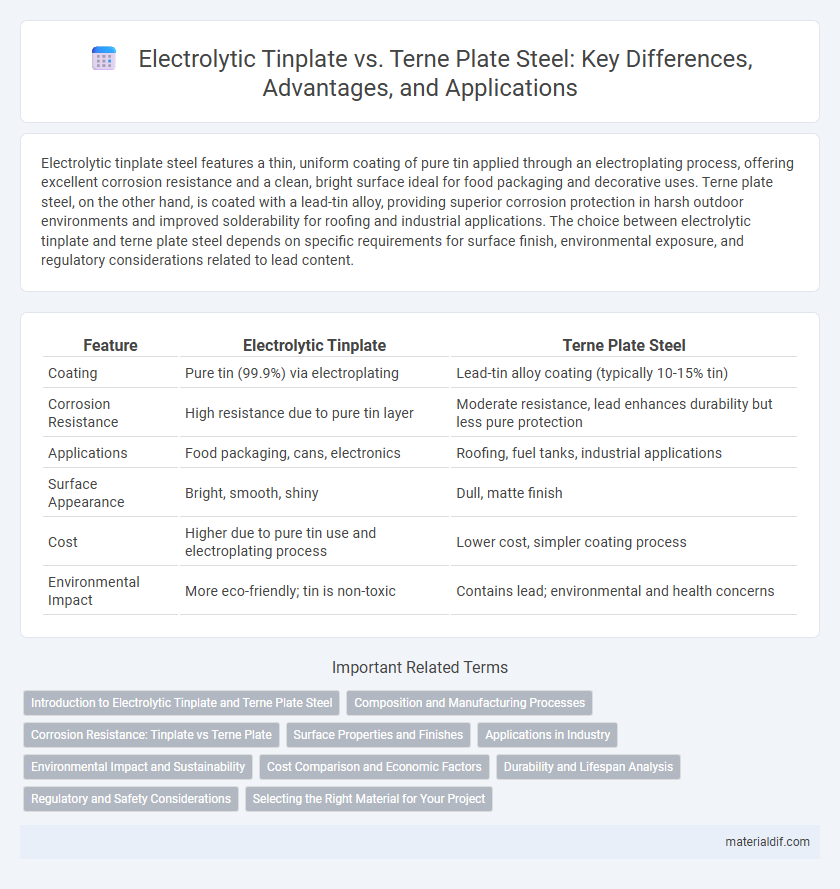

Electrolytic tinplate steel features a thin, uniform coating of pure tin applied through an electroplating process, offering excellent corrosion resistance and a clean, bright surface ideal for food packaging and decorative uses. Terne plate steel, on the other hand, is coated with a lead-tin alloy, providing superior corrosion protection in harsh outdoor environments and improved solderability for roofing and industrial applications. The choice between electrolytic tinplate and terne plate steel depends on specific requirements for surface finish, environmental exposure, and regulatory considerations related to lead content.

Table of Comparison

| Feature | Electrolytic Tinplate | Terne Plate Steel |

|---|---|---|

| Coating | Pure tin (99.9%) via electroplating | Lead-tin alloy coating (typically 10-15% tin) |

| Corrosion Resistance | High resistance due to pure tin layer | Moderate resistance, lead enhances durability but less pure protection |

| Applications | Food packaging, cans, electronics | Roofing, fuel tanks, industrial applications |

| Surface Appearance | Bright, smooth, shiny | Dull, matte finish |

| Cost | Higher due to pure tin use and electroplating process | Lower cost, simpler coating process |

| Environmental Impact | More eco-friendly; tin is non-toxic | Contains lead; environmental and health concerns |

Introduction to Electrolytic Tinplate and Terne Plate Steel

Electrolytic tinplate consists of steel sheets coated with a thin layer of pure tin through an electrolytic process, providing excellent corrosion resistance and solderability, ideal for food and beverage packaging. Terne plate steel features a coating of lead-tin alloy applied by hot-dipping, offering enhanced durability and resistance to atmospheric corrosion, commonly used in roofing and automotive applications. Both materials serve specialized industries, with electrolytic tinplate favored for hygiene-sensitive uses and terne plate for structural protection.

Composition and Manufacturing Processes

Electrolytic tinplate steel is composed primarily of low-carbon steel coated with a thin layer of pure tin through an electroplating process, ensuring uniform thickness and excellent corrosion resistance. Terne plate steel features a low-carbon steel substrate coated with a lead-tin alloy, typically 80-90% lead and 10-20% tin, applied via hot-dipping, providing enhanced weather resistance and durability. The critical difference in manufacturing lies in electrolytic deposition for tinplate, offering precise control over tin layer, whereas terne plate relies on hot-dip alloying for a thicker, more protective coating.

Corrosion Resistance: Tinplate vs Terne Plate

Electrolytic tinplate offers superior corrosion resistance due to its uniform tin coating, which provides an effective barrier against moisture and oxygen. Terne plate steel, coated with a lead-tin alloy, exhibits enhanced durability in high-temperature or acidic environments but is more susceptible to surface degradation over time. The choice between tinplate and terne plate depends on the specific application requirements for corrosion protection and environmental exposure.

Surface Properties and Finishes

Electrolytic tinplate steel features a smooth, bright, and corrosion-resistant surface achieved through an electrolytic process that deposits a uniform layer of tin, enhancing solderability and printability for food packaging and industrial uses. Terne plate steel is coated with a lead-tin alloy, resulting in a dull, matte finish that provides strong corrosion resistance and heat tolerance, making it suitable for roofing, fuel tanks, and chemical containers. The key surface difference lies in the electrolytic tinplate's shiny, uniform finish versus the terne plate's rougher, less reflective coating that prioritizes durability over aesthetics.

Applications in Industry

Electrolytic tinplate is widely used in the food and beverage industry for manufacturing cans and containers due to its corrosion resistance and excellent solderability. Terne plate steel, coated with a lead-tin alloy, is commonly applied in the roofing and automotive industries for its enhanced weather resistance and durability. Both materials serve specialized roles, with electrolytic tinplate preferred for sanitary packaging and terne plate favored for protective exterior applications.

Environmental Impact and Sustainability

Electrolytic tinplate steel features a thin, uniform tin coating applied through an electroplating process that ensures superior corrosion resistance and recyclability, contributing to reduced environmental impact. Terne plate steel, coated with a lead-tin alloy, presents challenges in sustainability due to lead content, which poses higher toxicity risks and complicates recycling efforts. The shift towards electrolytic tinplate supports sustainable steel production by minimizing hazardous waste and enhancing material recovery in circular economy initiatives.

Cost Comparison and Economic Factors

Electrolytic tinplate typically incurs higher production costs due to the refined tin coating process, which enhances corrosion resistance and surface finish, making it suitable for food packaging and high-quality containers. Terne plate steel is more cost-effective, utilizing a lead-tin alloy coating that provides moderate corrosion protection at a lower material and manufacturing expense, often preferred for roofing and automotive parts. Economic factors influencing choice include long-term durability requirements, environmental regulations on lead content, and total lifecycle cost, where electrolytic tinplate commands a premium justified by superior performance and recyclability.

Durability and Lifespan Analysis

Electrolytic tinplate steel, coated with pure tin, offers superior corrosion resistance and a longer lifespan compared to terne plate steel, which uses a lead-tin alloy coating prone to faster oxidation. The pure tin layer in electrolytic tinplate creates a robust barrier against moisture and acids, significantly enhancing durability in packaging and food containers. Terne plate steel's shorter durability makes it more suited for roofing and decorative applications rather than long-term exposure to harsh environments.

Regulatory and Safety Considerations

Electrolytic tinplate steel complies with stringent FDA regulations for food-contact applications due to its pure tin coating that prevents corrosion and contamination. Terne plate steel, coated with a lead-tin alloy, faces stricter environmental and safety restrictions because of lead content, limiting its use under regulations such as RoHS and EPA standards. Selecting steel for manufacturing requires careful evaluation of regulatory compliance to ensure safety and environmental sustainability in end-products.

Selecting the Right Material for Your Project

Electrolytic tinplate offers superior corrosion resistance and a smooth, clean surface ideal for food and beverage packaging, whereas terne plate steel provides excellent durability and heat resistance suited for roofing and automotive applications. Choosing between electrolytic tinplate and terne plate steel depends on project requirements such as exposure to moisture, heat levels, and desired longevity. Material properties like tin coating thickness, substrate strength, and environmental conditions must be carefully evaluated to ensure optimal performance and cost efficiency.

Electrolytic Tinplate vs Terne Plate Steel Infographic

materialdif.com

materialdif.com