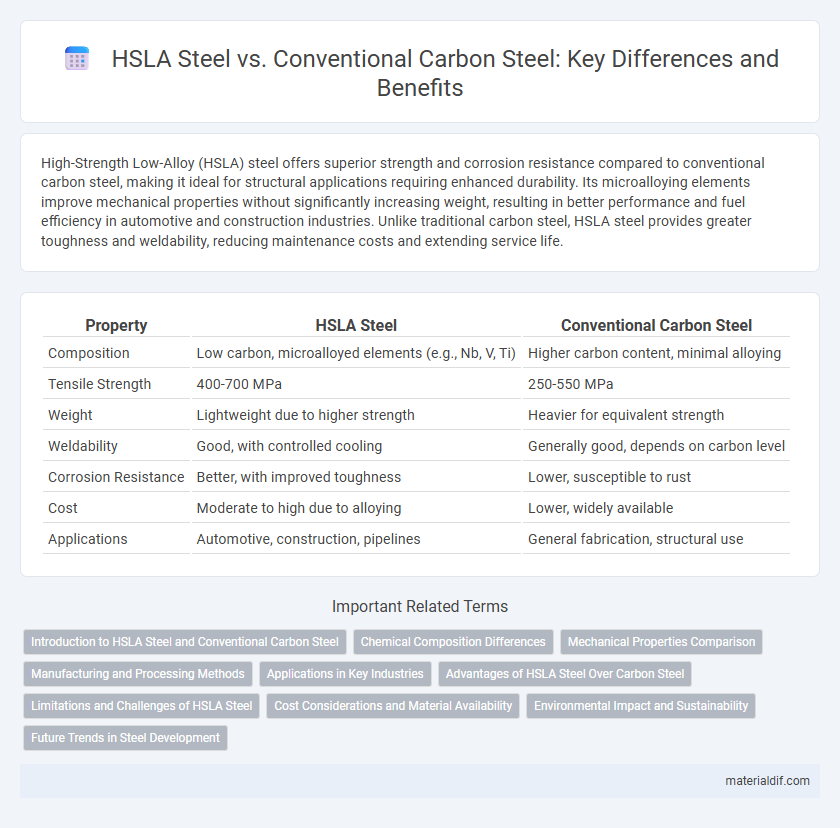

High-Strength Low-Alloy (HSLA) steel offers superior strength and corrosion resistance compared to conventional carbon steel, making it ideal for structural applications requiring enhanced durability. Its microalloying elements improve mechanical properties without significantly increasing weight, resulting in better performance and fuel efficiency in automotive and construction industries. Unlike traditional carbon steel, HSLA steel provides greater toughness and weldability, reducing maintenance costs and extending service life.

Table of Comparison

| Property | HSLA Steel | Conventional Carbon Steel |

|---|---|---|

| Composition | Low carbon, microalloyed elements (e.g., Nb, V, Ti) | Higher carbon content, minimal alloying |

| Tensile Strength | 400-700 MPa | 250-550 MPa |

| Weight | Lightweight due to higher strength | Heavier for equivalent strength |

| Weldability | Good, with controlled cooling | Generally good, depends on carbon level |

| Corrosion Resistance | Better, with improved toughness | Lower, susceptible to rust |

| Cost | Moderate to high due to alloying | Lower, widely available |

| Applications | Automotive, construction, pipelines | General fabrication, structural use |

Introduction to HSLA Steel and Conventional Carbon Steel

High-Strength Low-Alloy (HSLA) steel offers improved mechanical properties and greater resistance to corrosion compared to conventional carbon steel, making it ideal for structural applications requiring enhanced strength and durability. HSLA steels contain small amounts of alloying elements such as chromium, nickel, and copper, which contribute to their superior toughness and weldability, whereas conventional carbon steels primarily rely on carbon content for hardness and strength. This results in HSLA steel providing better performance with lower weight and increased cost-effectiveness in industries like automotive, construction, and shipbuilding.

Chemical Composition Differences

High-Strength Low-Alloy (HSLA) steel contains lower carbon content, typically less than 0.2%, combined with microalloying elements such as niobium, vanadium, and titanium to enhance strength and toughness. Conventional carbon steel features higher carbon levels, often ranging from 0.2% to 0.6%, which increases hardness but reduces ductility. The addition of alloying elements in HSLA steel improves corrosion resistance and weldability compared to the simpler chemical composition of conventional carbon steel.

Mechanical Properties Comparison

High-Strength Low-Alloy (HSLA) steel exhibits superior mechanical properties compared to conventional carbon steel, including higher tensile strength typically ranging from 350 to 700 MPa versus 250 to 400 MPa for carbon steel. HSLA steel offers enhanced yield strength, improved toughness, and better resistance to corrosion and wear due to its microalloying elements such as niobium, vanadium, and titanium. This combination of strength and durability allows HSLA steel to be used in applications demanding lightweight yet high-performance materials, outperforming traditional carbon steel in structural and automotive industries.

Manufacturing and Processing Methods

High-Strength Low-Alloy (HSLA) steel employs advanced thermomechanical processing techniques such as controlled rolling and accelerated cooling, resulting in refined grain structures and superior mechanical properties compared to conventional carbon steel. Conventional carbon steel typically undergoes simpler manufacturing processes like hot rolling and basic heat treatments, which provide lower strength and less resistance to corrosion. The alloying elements in HSLA steel, including microalloying with niobium, vanadium, and titanium, facilitate precipitation strengthening during processing, offering enhanced durability and weldability.

Applications in Key Industries

High-Strength Low-Alloy (HSLA) steel offers superior strength-to-weight ratios and enhanced corrosion resistance compared to conventional carbon steel, making it ideal for automotive manufacturing and structural engineering. In the construction industry, HSLA steel enables lighter, more durable frameworks that improve seismic resistance and reduce overall costs. Oil and gas pipelines benefit from HSLA's toughness and weldability, ensuring long-term performance under harsh environmental conditions.

Advantages of HSLA Steel Over Carbon Steel

High-Strength Low-Alloy (HSLA) steel offers superior strength-to-weight ratio compared to conventional carbon steel, enabling lighter and more durable structural components. Enhanced corrosion resistance and improved weldability reduce maintenance costs and extend the service life of HSLA steel in demanding environments. The optimized microstructure of HSLA steel contributes to better toughness and formability, making it an ideal choice for automotive, construction, and industrial applications.

Limitations and Challenges of HSLA Steel

High-Strength Low-Alloy (HSLA) steel exhibits enhanced mechanical properties compared to conventional carbon steel, but faces challenges such as increased production costs due to the need for precise alloying and controlled processing techniques. Limitations include reduced weldability and susceptibility to embrittlement under certain service conditions, impacting its performance in extreme environments. The complexity of balancing strength, toughness, and corrosion resistance often requires specialized expertise to optimize HSLA steel applications effectively.

Cost Considerations and Material Availability

High-Strength Low-Alloy (HSLA) steel offers improved mechanical properties compared to conventional carbon steel, often resulting in lower overall costs due to reduced material weight and enhanced durability. Although HSLA steel has a higher initial price than carbon steel, its cost-effectiveness increases in applications requiring corrosion resistance and high strength-to-weight ratios. Material availability for HSLA steel is generally good, but specialized alloying elements may influence lead times and pricing compared to the more widely available conventional carbon steel.

Environmental Impact and Sustainability

High-Strength Low-Alloy (HSLA) steel demonstrates a lower environmental impact compared to conventional carbon steel due to its superior strength-to-weight ratio, which reduces the amount of material required and thus lowers energy consumption in production and transportation. HSLA steel's enhanced corrosion resistance extends the lifespan of structures, decreasing the frequency of repairs and replacements, thereby minimizing resource depletion and waste generation. The manufacturing process of HSLA steel typically involves lower greenhouse gas emissions than carbon steel production, contributing to improved sustainability in construction and manufacturing industries.

Future Trends in Steel Development

High-Strength Low-Alloy (HSLA) steel is gaining prominence over conventional carbon steel due to its superior strength-to-weight ratio, enhanced corrosion resistance, and improved weldability, driving innovation in automotive and structural applications. Future trends emphasize the integration of advanced metallurgy techniques, such as microalloying and thermomechanical processing, to further optimize mechanical properties and reduce environmental impact. Industry projections forecast increased adoption of HSLA steels in infrastructure and transportation sectors, supporting sustainability goals through lower carbon footprints and extended service life.

High-Strength Low-Alloy (HSLA) Steel vs Conventional Carbon Steel Infographic

materialdif.com

materialdif.com