Spring steel is characterized by its excellent elasticity and high fatigue resistance, making it ideal for applications requiring repeated flexing, such as springs and suspension components. High-speed steel, on the other hand, excels in hardness and heat resistance, enabling it to maintain sharp cutting edges at elevated temperatures, which is essential for cutting tools and machining applications. While spring steel prioritizes flexibility and fatigue strength, high-speed steel focuses on durability and performance under extreme thermal stress.

Table of Comparison

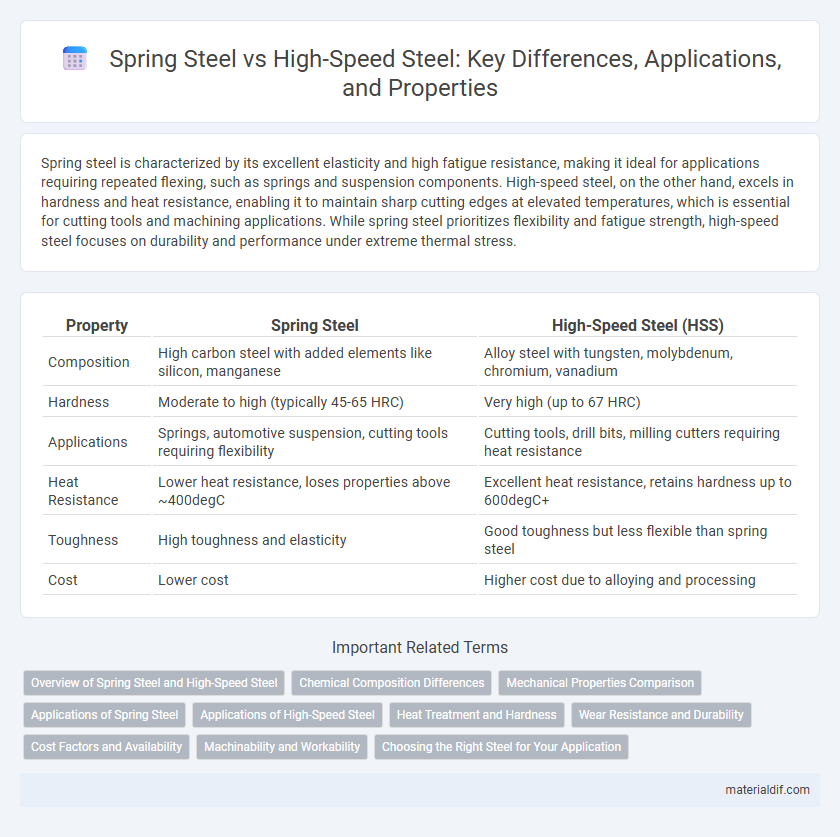

| Property | Spring Steel | High-Speed Steel (HSS) |

|---|---|---|

| Composition | High carbon steel with added elements like silicon, manganese | Alloy steel with tungsten, molybdenum, chromium, vanadium |

| Hardness | Moderate to high (typically 45-65 HRC) | Very high (up to 67 HRC) |

| Applications | Springs, automotive suspension, cutting tools requiring flexibility | Cutting tools, drill bits, milling cutters requiring heat resistance |

| Heat Resistance | Lower heat resistance, loses properties above ~400degC | Excellent heat resistance, retains hardness up to 600degC+ |

| Toughness | High toughness and elasticity | Good toughness but less flexible than spring steel |

| Cost | Lower cost | Higher cost due to alloying and processing |

Overview of Spring Steel and High-Speed Steel

Spring steel is a high-carbon steel known for its exceptional elasticity and strength, commonly used in manufacturing springs and flexible components that require durability under repeated stress. High-speed steel (HSS) contains additional alloying elements such as tungsten, molybdenum, and chromium, providing superior hardness, wear resistance, and heat resistance, making it ideal for cutting tools and machining applications. Both steels offer specialized performance characteristics tailored to their respective industrial uses, with spring steel excelling in flexibility and high-speed steel in thermal stability and hardness.

Chemical Composition Differences

Spring steel typically contains 0.5-1.0% carbon, along with manganese, silicon, and small amounts of chromium or vanadium to enhance elasticity and tensile strength. High-speed steel features higher carbon content, usually 0.7-1.5%, combined with significant amounts of tungsten, molybdenum, chromium, vanadium, and cobalt to improve hardness, heat resistance, and wear properties. The distinct alloying elements in high-speed steel enable it to maintain cutting performance at elevated temperatures, whereas spring steel's composition prioritizes flexibility and fatigue resistance.

Mechanical Properties Comparison

Spring steel exhibits exceptional elasticity and high tensile strength, enabling it to endure repeated stress without deformation, making it ideal for applications like springs and high-stress mechanical components. High-speed steel offers superior hardness and wear resistance at elevated temperatures, maintaining cutting edge sharpness during high-speed machining operations. The mechanical properties highlight spring steel's flexibility and resilience, contrasted with high-speed steel's hardness and thermal stability for demanding cutting tools.

Applications of Spring Steel

Spring steel is primarily used in applications requiring high yield strength and flexibility, such as automotive suspension springs, trampolines, and industrial machinery components. Its ability to withstand repeated stress without deforming makes it ideal for manufacturing retainers, clips, and precision tools. Compared to high-speed steel, which is favored for cutting tools due to its hardness and heat resistance, spring steel excels in dynamic load-bearing environments.

Applications of High-Speed Steel

High-speed steel (HSS) is predominantly used in cutting tools such as drills, taps, and milling cutters due to its excellent hardness, wear resistance, and ability to retain these properties at high temperatures. Unlike spring steel, which is optimized for flexibility and tensile strength in applications like automotive suspensions and springs, HSS excels in machining and metalworking industries where high-speed operation and precision are critical. The durability and heat resistance of high-speed steel make it ideal for manufacturing tools that require sustained sharpness and toughness under extreme conditions.

Heat Treatment and Hardness

Spring steel undergoes heat treatment processes like quenching and tempering to achieve elasticity and moderate hardness, typically around 40-60 HRC, which allows it to return to its original shape after bending. High-speed steel (HSS) is heat treated through a complex cycle involving hardening and tempering at high temperatures, resulting in superior hardness levels of approximately 62-67 HRC and exceptional wear resistance for cutting applications. The calibrated heat treatment parameters in HSS enable it to maintain hardness and edge retention even at elevated temperatures, unlike spring steel.

Wear Resistance and Durability

Spring steel exhibits excellent flexibility and toughness, making it highly resilient to repeated stress, but it typically offers moderate wear resistance compared to high-speed steel. High-speed steel (HSS) is engineered with alloying elements such as tungsten, molybdenum, and vanadium, which enhance its hardness, wear resistance, and ability to retain cutting edges at elevated temperatures. The superior durability of high-speed steel makes it ideal for cutting tools subjected to intense friction and heat, whereas spring steel is preferred for applications requiring elasticity and fatigue resistance.

Cost Factors and Availability

Spring steel is generally more cost-effective and widely available due to its simpler alloy composition and prevalent use in automotive and industrial applications. High-speed steel (HSS) commands a higher price because of its complex alloying elements like tungsten, molybdenum, and cobalt, which enhance heat resistance and hardness for cutting tools. Availability of HSS is more limited and specialized, typically sourced from niche suppliers catering to tool manufacturing industries.

Machinability and Workability

Spring steel offers superior workability due to its high flexibility and tensile strength, making it ideal for components requiring elasticity and impact resistance. High-speed steel excels in machinability under high-temperature conditions, maintaining hardness and wear resistance during cutting operations. While spring steel is preferred for forming and bending, high-speed steel is optimized for precision machining and tool manufacturing.

Choosing the Right Steel for Your Application

Spring steel offers exceptional elasticity and fatigue resistance, making it ideal for applications requiring repeated flexing, such as springs and clips. High-speed steel provides superior hardness and heat resistance, suitable for cutting tools and machining where high temperatures are common. Selecting the right steel depends on whether flexibility or hardness under heat is the primary performance criterion for your specific application.

Spring steel vs High-speed steel Infographic

materialdif.com

materialdif.com