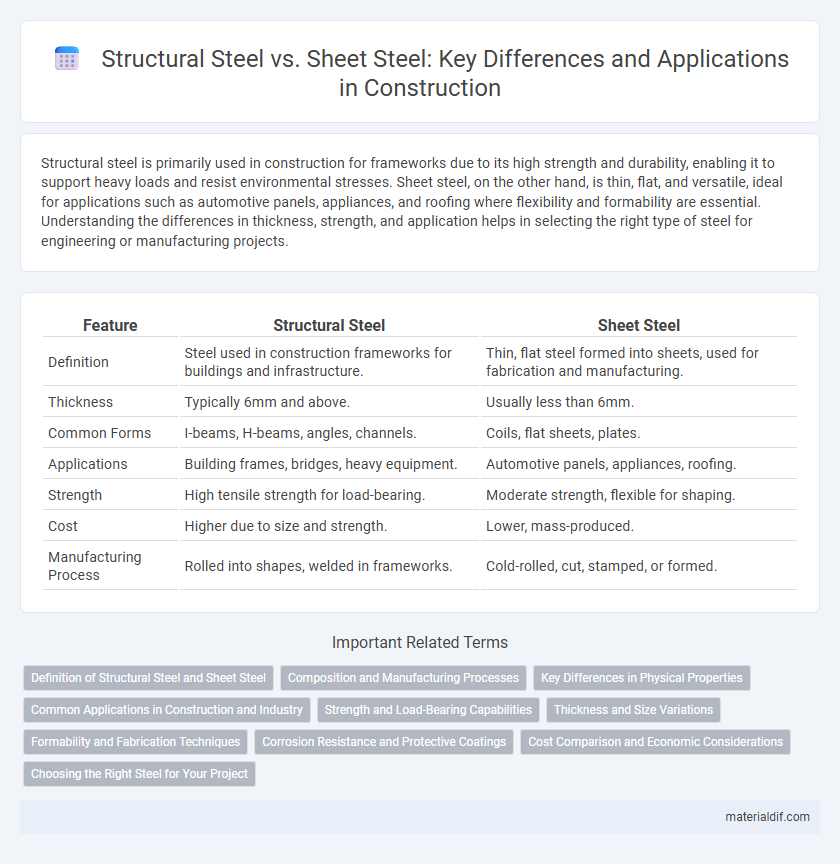

Structural steel is primarily used in construction for frameworks due to its high strength and durability, enabling it to support heavy loads and resist environmental stresses. Sheet steel, on the other hand, is thin, flat, and versatile, ideal for applications such as automotive panels, appliances, and roofing where flexibility and formability are essential. Understanding the differences in thickness, strength, and application helps in selecting the right type of steel for engineering or manufacturing projects.

Table of Comparison

| Feature | Structural Steel | Sheet Steel |

|---|---|---|

| Definition | Steel used in construction frameworks for buildings and infrastructure. | Thin, flat steel formed into sheets, used for fabrication and manufacturing. |

| Thickness | Typically 6mm and above. | Usually less than 6mm. |

| Common Forms | I-beams, H-beams, angles, channels. | Coils, flat sheets, plates. |

| Applications | Building frames, bridges, heavy equipment. | Automotive panels, appliances, roofing. |

| Strength | High tensile strength for load-bearing. | Moderate strength, flexible for shaping. |

| Cost | Higher due to size and strength. | Lower, mass-produced. |

| Manufacturing Process | Rolled into shapes, welded in frameworks. | Cold-rolled, cut, stamped, or formed. |

Definition of Structural Steel and Sheet Steel

Structural steel is a category of steel used primarily in construction, characterized by its high strength and durability, making it ideal for building frameworks, bridges, and other load-bearing structures. Sheet steel refers to steel products formed into thin, flat pieces through rolling processes, commonly used in automotive panels, appliances, and roofing. Structural steel typically has a higher carbon content and specific mechanical properties for structural integrity, whereas sheet steel emphasizes formability and surface finish.

Composition and Manufacturing Processes

Structural steel is primarily composed of carbon, manganese, and trace elements, manufactured through processes like hot rolling and welding to form beams, columns, and frameworks for construction. Sheet steel features a thinner, more uniform composition with increased carbon and alloy content, produced via cold rolling and annealing to create flat, flexible sheets for automotive and appliance industries. The distinct manufacturing methods emphasize structural steel's strength and durability, while sheet steel prioritizes surface quality and formability.

Key Differences in Physical Properties

Structural steel exhibits higher tensile strength and greater thickness compared to sheet steel, making it ideal for load-bearing applications in construction and infrastructure. Sheet steel is thinner, more flexible, and easier to form, commonly used in automotive panels and appliances where lightweight and malleability are essential. The density and yield strength of structural steel provide superior durability, whereas sheet steel offers enhanced surface finish and corrosion resistance through various coatings.

Common Applications in Construction and Industry

Structural steel, known for its high strength and durability, is commonly used in building frameworks, bridges, and large industrial structures where load-bearing capacity is critical. Sheet steel, characterized by its thin, flat form, is widely applied in roofing, wall panels, and ductwork, providing lightweight and versatile solutions. Both materials serve crucial roles in construction and industry, with structural steel supporting heavy structural demands and sheet steel enabling flexible, surface-oriented applications.

Strength and Load-Bearing Capabilities

Structural steel exhibits superior strength and load-bearing capabilities compared to sheet steel due to its thicker profiles and engineered design for construction applications. Sheet steel, typically thinner and more flexible, is better suited for lightweight uses rather than heavy structural loads. The inherent tensile strength and durability of structural steel make it ideal for frameworks, beams, and columns supporting significant weight.

Thickness and Size Variations

Structural steel typically comes in larger sizes and thicker gauges designed for heavy load-bearing applications in construction, such as beams, columns, and girders. Sheet steel is manufactured in thinner gauges, ranging from 0.2 mm to 6 mm, and is primarily used for surface applications like roofing, automotive panels, and appliances. Thickness variations in structural steel can exceed 100 mm, whereas sheet steel is produced in standardized flat sheets or coils, emphasizing versatility and ease of fabrication.

Formability and Fabrication Techniques

Structural steel offers superior formability for creating large, load-bearing constructions due to its higher thickness and strength, enabling it to be welded, bolted, or riveted with ease. Sheet steel, characterized by its thinness and flexibility, excels in fabrication techniques such as stamping, bending, and roll forming, making it ideal for detailed components and automotive panels. Differences in thermal conductivity and tensile strength between structural and sheet steel influence their respective suitability for heavy structural frameworks versus precision-fabricated parts.

Corrosion Resistance and Protective Coatings

Structural steel typically features higher corrosion resistance due to thicker protective coatings like galvanization or weathering steel alloys designed to withstand harsh environmental conditions. Sheet steel often relies on thinner coatings such as zinc or polymer layers for protection, making it more susceptible to surface damage and rust over time. The choice of protective coatings directly impacts the durability and maintenance requirements of both structural steel and sheet steel in corrosive environments.

Cost Comparison and Economic Considerations

Structural steel typically incurs higher costs due to its thicker dimensions and enhanced load-bearing properties compared to sheet steel, which is thinner and more affordable for lighter applications. Economic considerations favor sheet steel for projects requiring flexibility and cost-efficiency, while structural steel justifies its expense in heavy construction due to superior durability and strength. Evaluating project requirements and budget constraints is essential for optimizing material selection between structural and sheet steel.

Choosing the Right Steel for Your Project

Selecting the right steel for your project depends on the application and load requirements; structural steel offers high strength and durability for frameworks and heavy construction, while sheet steel is ideal for lighter, more flexible uses such as cladding or automotive components. Structural steel typically comes in beams, columns, and channels designed to bear significant weight, whereas sheet steel provides a thin, versatile surface that can be easily cut and formed. Understanding the mechanical properties and shape requirements ensures optimal performance and cost-effectiveness in construction or manufacturing projects.

Structural Steel vs Sheet Steel Infographic

materialdif.com

materialdif.com