304 steel is highly durable and corrosion-resistant, making it ideal for general applications, while 316 steel offers enhanced resistance to corrosion and chemicals due to its molybdenum content, making it suitable for marine and industrial environments. The choice between 304 and 316 steel depends on exposure conditions, with 316 preferred for harsher climates or chemical exposure. Both types are widely used in steel pet products for their strength and longevity.

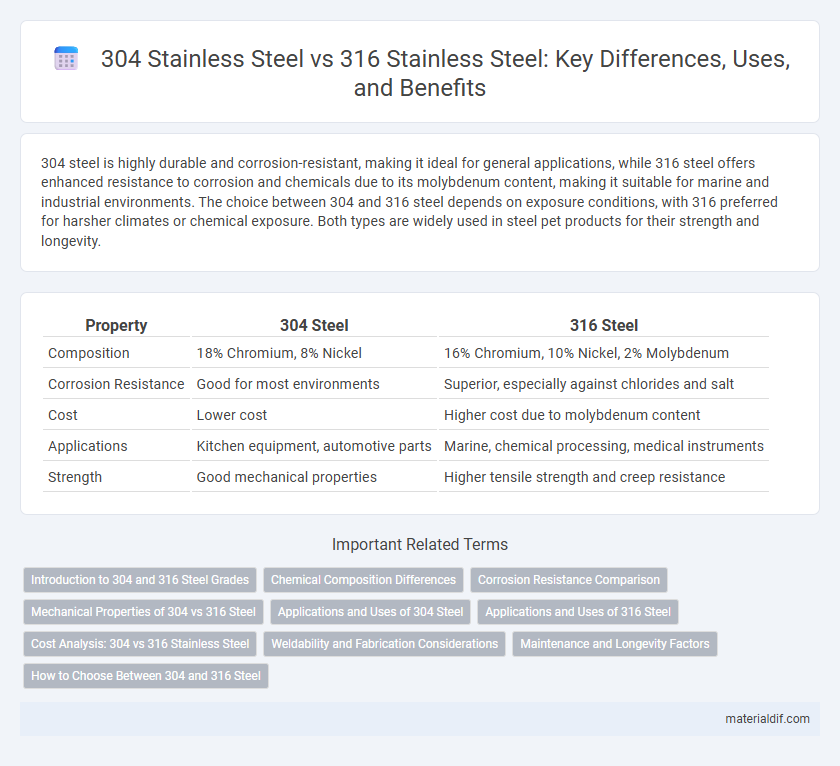

Table of Comparison

| Property | 304 Steel | 316 Steel |

|---|---|---|

| Composition | 18% Chromium, 8% Nickel | 16% Chromium, 10% Nickel, 2% Molybdenum |

| Corrosion Resistance | Good for most environments | Superior, especially against chlorides and salt |

| Cost | Lower cost | Higher cost due to molybdenum content |

| Applications | Kitchen equipment, automotive parts | Marine, chemical processing, medical instruments |

| Strength | Good mechanical properties | Higher tensile strength and creep resistance |

Introduction to 304 and 316 Steel Grades

304 steel, also known as 18-8 stainless steel, contains approximately 18% chromium and 8% nickel, offering excellent corrosion resistance and versatility for general-purpose applications. 316 steel includes molybdenum, typically 2-3%, enhancing resistance to pitting and crevice corrosion, especially in marine and chloride-rich environments. Both grades are austenitic stainless steels favored in construction, food processing, and chemical industries due to their durability and ease of fabrication.

Chemical Composition Differences

304 steel primarily contains 18-20% chromium and 8-10.5% nickel, offering good corrosion resistance and formability. In contrast, 316 steel includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, which significantly enhances its resistance to chlorides and marine environments. The addition of molybdenum in 316 steel provides superior protection against pitting and crevice corrosion compared to 304 steel.

Corrosion Resistance Comparison

304 steel offers good corrosion resistance in a variety of environments, primarily because of its 18% chromium and 8% nickel composition. 316 steel enhances corrosion resistance further by adding 2-3% molybdenum, which significantly improves its performance against chlorides and marine environments. This makes 316 steel the preferred choice for applications exposed to saltwater or harsh chemical conditions.

Mechanical Properties of 304 vs 316 Steel

304 steel offers tensile strength around 75,000 psi and yield strength near 30,000 psi, while 316 steel exhibits slightly higher tensile strength typically about 80,000 psi and yield strength close to 35,000 psi. The greater mechanical strength of 316 steel correlates with enhanced resistance to corrosion and high-temperature environments due to its molybdenum content. Both grades provide excellent ductility and toughness, but 316 steel's superior mechanical properties make it more suitable for demanding applications requiring enhanced durability.

Applications and Uses of 304 Steel

304 steel is widely used in kitchen equipment, food processing, and chemical containers due to its excellent corrosion resistance and ease of fabrication. It finds applications in architectural structures, automotive trims, and household appliances where moderate corrosion resistance and aesthetic appeal are required. The versatility and cost-effectiveness of 304 stainless steel make it a preferred choice for general-purpose use across various industries.

Applications and Uses of 316 Steel

316 steel is widely used in marine environments and chemical processing due to its superior corrosion resistance against chlorides and industrial solvents, making it ideal for boat fittings, chemical containers, and heat exchangers. Its enhanced chromium and molybdenum content provide excellent durability in aggressive environments, which is crucial for pharmaceutical manufacturing and food processing equipment. The alloy's resistance to pitting and crevice corrosion ensures reliability in medical implants and architectural structures exposed to harsh weather conditions.

Cost Analysis: 304 vs 316 Stainless Steel

304 stainless steel generally costs less than 316 stainless steel due to its lower nickel and molybdenum content, making it more economically viable for applications with budget constraints. The price difference is influenced by 316's enhanced corrosion resistance, especially in chloride-rich or marine environments, which justifies its higher cost for specialized uses. Evaluating long-term maintenance and replacement expenses often reveals that the initial higher investment in 316 stainless steel can result in better overall value in harsh conditions.

Weldability and Fabrication Considerations

304 steel offers excellent weldability with standard welding techniques such as TIG and MIG, making it suitable for general fabrication where corrosion resistance demands are moderate. In contrast, 316 steel, enriched with molybdenum, provides superior corrosion resistance in aggressive environments but requires careful control of heat input during welding to prevent carbide precipitation and maintain its corrosion resistance properties. Both alloys respond well to common fabrication processes, but 316 steel often necessitates post-weld heat treatment or use of low carbon variants (316L) to enhance weld integrity in critical applications.

Maintenance and Longevity Factors

304 steel offers good corrosion resistance and requires routine cleaning to maintain its appearance and structural integrity in most environments. 316 steel contains molybdenum, enhancing its resistance to chlorides and marine exposure, resulting in lower maintenance needs and extended lifespan in harsh or saline conditions. Choosing 316 steel significantly improves longevity and reduces the frequency of repairs or replacements in corrosive environments.

How to Choose Between 304 and 316 Steel

Choosing between 304 and 316 steel depends on the specific application environment and corrosion resistance requirements. 316 steel contains molybdenum, which provides enhanced resistance to chloride and marine environments, making it ideal for use in chemical processing or coastal structures, while 304 steel is suitable for general indoor use where lower corrosion resistance is acceptable. Cost considerations also play a role, as 316 steel is typically more expensive due to its improved alloy composition.

304 Steel vs 316 Steel Infographic

materialdif.com

materialdif.com