Seamless steel offers superior strength and uniformity due to its continuous manufacturing process without joints or welds, making it ideal for high-pressure applications. Welded steel, created by fusing pieces together, provides cost efficiency and flexibility in size and shape but may have weaker points at the welds under stress. Choosing between seamless and welded steel depends on the specific requirements of durability, pressure tolerance, and budget constraints.

Table of Comparison

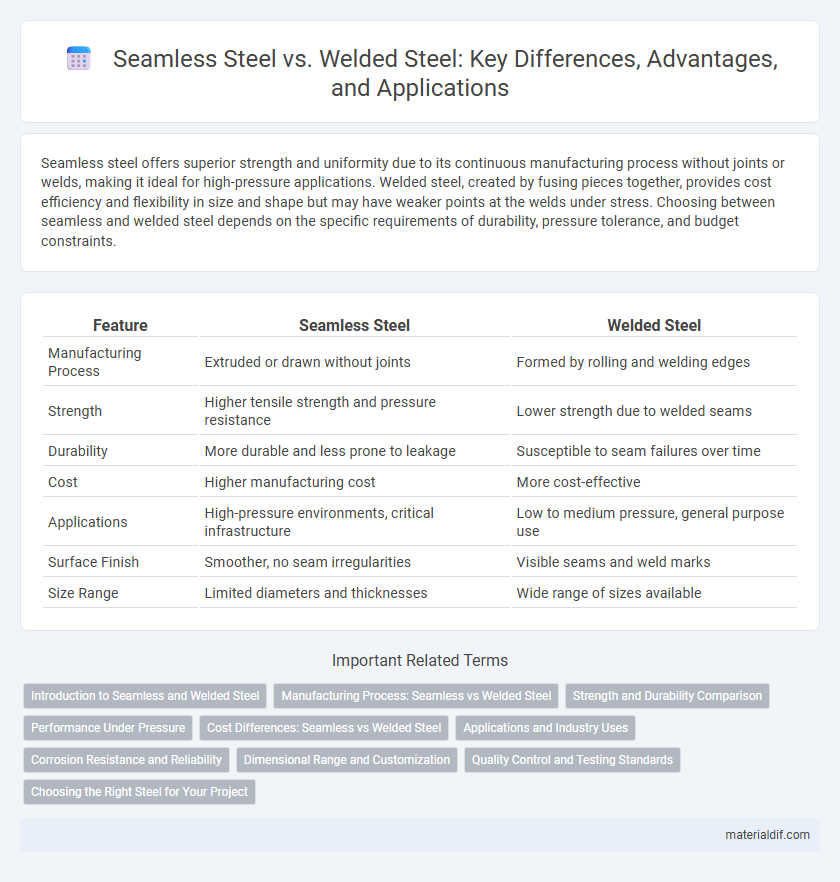

| Feature | Seamless Steel | Welded Steel |

|---|---|---|

| Manufacturing Process | Extruded or drawn without joints | Formed by rolling and welding edges |

| Strength | Higher tensile strength and pressure resistance | Lower strength due to welded seams |

| Durability | More durable and less prone to leakage | Susceptible to seam failures over time |

| Cost | Higher manufacturing cost | More cost-effective |

| Applications | High-pressure environments, critical infrastructure | Low to medium pressure, general purpose use |

| Surface Finish | Smoother, no seam irregularities | Visible seams and weld marks |

| Size Range | Limited diameters and thicknesses | Wide range of sizes available |

Introduction to Seamless and Welded Steel

Seamless steel is manufactured by extruding a solid billet to form a hollow tube without joints, resulting in uniform strength and higher resistance to pressure, making it ideal for high-stress applications like pipelines and pressure vessels. Welded steel is produced by rolling steel and welding the edges together, offering cost efficiency and versatility for structural uses such as construction and automotive industries. Both types provide unique mechanical properties, with seamless steel excelling in durability and welded steel favored for large-scale fabrication projects.

Manufacturing Process: Seamless vs Welded Steel

Seamless steel is manufactured through a hot rolling or extrusion process, which involves heating a solid billet and piercing it to create a hollow tube without any joints, resulting in a uniform structure and enhanced strength. Welded steel is produced by rolling steel plates or strips into a cylindrical shape and then welding the edges together using methods such as electric resistance welding (ERW) or submerged arc welding (SAW), which can introduce seams and potential weak points. The seamless process eliminates weld joints, offering higher pressure resistance and durability, while welded steel provides cost-effective and versatile solutions suitable for lower pressure applications.

Strength and Durability Comparison

Seamless steel boasts superior strength due to its uniform molecular structure, which eliminates weak points typically found in welded seams. Welded steel, while often more cost-effective, may contain stress concentrations along the weld lines that can reduce overall durability under high pressure or impact. In applications demanding maximum resilience and long-term performance, seamless steel generally outperforms welded steel by offering enhanced resistance to fatigue and corrosion.

Performance Under Pressure

Seamless steel exhibits superior performance under high-pressure conditions due to its uniform grain structure and absence of welded joints, reducing the risk of failure or leaks. Welded steel, while generally more cost-effective, may contain weak points along the weld seams that can compromise strength under extreme pressure. Industry applications requiring enhanced durability and resistance, such as high-pressure pipelines and boilers, typically favor seamless steel for its reliability and safety.

Cost Differences: Seamless vs Welded Steel

Seamless steel pipes typically incur higher manufacturing costs due to their complex, material-intensive production process, which involves extruding and drawing solid billets without seams. Welded steel pipes are more cost-effective, made by rolling and welding steel plates or strips, resulting in lower raw material wastage and faster production times. The cost difference between seamless and welded steel significantly impacts budget decisions in industries such as oil and gas, construction, and automotive manufacturing.

Applications and Industry Uses

Seamless steel tubes are preferred in high-pressure applications such as oil and gas pipelines, automotive components, and aerospace due to their superior strength and resistance to corrosion. Welded steel pipes are widely used in construction, water transportation, and low-pressure fluid conveyance because of their cost-effectiveness and ease of manufacturing. Industries like chemical processing, power generation, and structural engineering rely on both seamless and welded steel products based on specific requirements for durability, pressure tolerance, and fabrication complexity.

Corrosion Resistance and Reliability

Seamless steel exhibits superior corrosion resistance due to its uniform, non-porous structure, minimizing the risk of cracks and crevice corrosion common in welded steel joints. Welded steel, while offering cost efficiency and ease of fabrication, often requires additional corrosion-resistant coatings or treatments to enhance durability and prevent failure at weld seams. Reliability in high-pressure or corrosive environments typically favors seamless steel for its integral strength and reduced susceptibility to corrosive degradation.

Dimensional Range and Customization

Seamless steel offers narrower dimensional ranges, typically available in smaller diameters up to 24 inches, providing superior strength and uniformity ideal for high-pressure applications. Welded steel pipes accommodate wider dimensional variations, from small to very large diameters exceeding 120 inches, with extensive customization options in wall thickness and length, making them suitable for diverse industrial needs. Custom fabrication in welded steel allows tailored designs for complex projects, whereas seamless steel relies more on standardized sizes with limited customization capabilities.

Quality Control and Testing Standards

Seamless steel undergoes rigorous quality control processes, including ultrasonic and magnetic particle inspection, to ensure uniformity and absence of weld defects, meeting stringent ASTM and ISO standards. Welded steel quality control involves extensive non-destructive testing such as radiographic and dye penetrant inspections to detect weld seam integrity issues, adhering to AWS and EN testing protocols. Both types require hydrostatic testing for pressure tolerance verification, but seamless steel typically offers superior consistency due to its homogeneous structure.

Choosing the Right Steel for Your Project

Seamless steel offers superior strength and corrosion resistance due to its uniform structure, making it ideal for high-pressure applications. Welded steel provides cost efficiency and flexibility in size and thickness, suitable for structural projects where customization is essential. Evaluating project requirements like load capacity, environmental exposure, and budget helps determine whether seamless or welded steel is the optimal choice.

Seamless Steel vs Welded Steel Infographic

materialdif.com

materialdif.com