Spring steel is specifically designed for high yield strength and flexibility, making it ideal for applications requiring elasticity and resilience, such as springs and suspension components. Tool steel, on the other hand, is engineered for hardness, wear resistance, and the ability to retain a sharp edge, which makes it suitable for cutting, shaping, and machining tools. Both steels offer unique mechanical properties tailored to different industrial needs, with spring steel optimizing toughness and tool steel emphasizing durability under high-stress conditions.

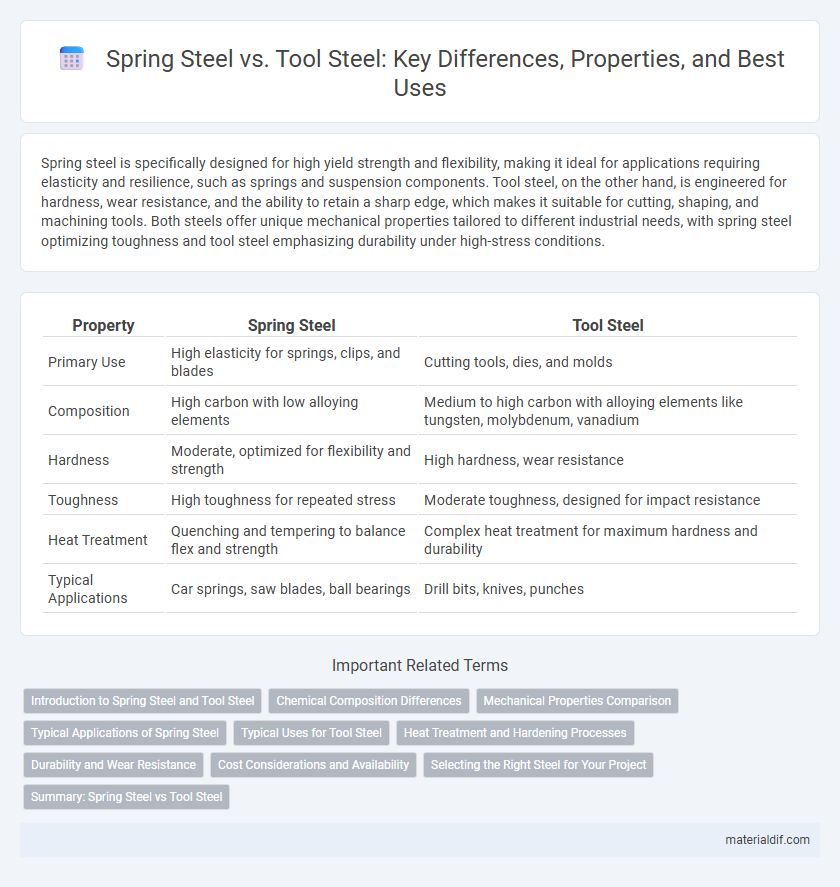

Table of Comparison

| Property | Spring Steel | Tool Steel |

|---|---|---|

| Primary Use | High elasticity for springs, clips, and blades | Cutting tools, dies, and molds |

| Composition | High carbon with low alloying elements | Medium to high carbon with alloying elements like tungsten, molybdenum, vanadium |

| Hardness | Moderate, optimized for flexibility and strength | High hardness, wear resistance |

| Toughness | High toughness for repeated stress | Moderate toughness, designed for impact resistance |

| Heat Treatment | Quenching and tempering to balance flex and strength | Complex heat treatment for maximum hardness and durability |

| Typical Applications | Car springs, saw blades, ball bearings | Drill bits, knives, punches |

Introduction to Spring Steel and Tool Steel

Spring steel is a high-carbon steel known for its exceptional elasticity and ability to return to its original shape after bending or twisting, making it ideal for manufacturing springs, clips, and retention components. Tool steel contains various alloying elements such as tungsten, molybdenum, and vanadium, designed for high hardness, wear resistance, and toughness, which is essential for cutting, machining, and forming tools. Both steels serve critical roles in industrial applications, with spring steel emphasizing flexibility and tool steel focusing on durability under severe conditions.

Chemical Composition Differences

Spring steel primarily contains high carbon content, typically ranging from 0.5% to 1.0%, with elements like manganese enhancing its elasticity and tensile strength. Tool steel features a more complex chemical composition with higher alloying elements such as tungsten, molybdenum, chromium, and vanadium, which improve hardness, wear resistance, and heat tolerance. The distinct variations in carbon concentration and alloying elements define the suitability of spring steel for flexible applications and tool steel for machining and cutting tools.

Mechanical Properties Comparison

Spring steel exhibits high yield strength and excellent elasticity, making it ideal for applications requiring repeated flexing without deformation. Tool steel offers superior hardness, wear resistance, and toughness, suited for cutting, shaping, and forming tools under high-stress conditions. Comparing mechanical properties, spring steel emphasizes resilience and fatigue resistance, while tool steel prioritizes hardness and compressive strength.

Typical Applications of Spring Steel

Spring steel is commonly used in applications requiring high yield strength and flexibility, such as automotive suspension components, springs, and clips. Its excellent fatigue resistance makes it ideal for manufacturing saw blades, knives, and torsion bars. Unlike tool steel, spring steel is favored in applications where elasticity under stress is critical for performance.

Typical Uses for Tool Steel

Tool steel is primarily utilized in manufacturing cutting tools, dies, molds, and stamping tools due to its exceptional hardness and resistance to wear. It is ideal for applications requiring high durability and the ability to retain a sharp edge under extreme conditions. Common sectors employing tool steel include automotive, aerospace, and metalworking industries for precision tooling and heavy-duty component fabrication.

Heat Treatment and Hardening Processes

Spring steel undergoes controlled heat treatment processes such as quenching and tempering to achieve its characteristic high elasticity and fatigue resistance, typically involving temperatures between 800degC and 900degC for austenitizing before rapid cooling. Tool steel requires precise heat treatment cycles, including austenitizing, quenching, and tempering at specific temperatures depending on the grade (e.g., A2, D2, O1), to develop superior hardness, wear resistance, and toughness essential for cutting and shaping applications. The hardening of spring steel focuses on maintaining flexibility and recovery, while tool steel hardening emphasizes maximum hardness and edge retention through careful temperature control and cooling rates.

Durability and Wear Resistance

Spring steel offers exceptional flexibility and high durability, making it ideal for applications requiring repeated stress without permanent deformation. Tool steel, enriched with elements like tungsten and vanadium, provides superior wear resistance and hardness, essential for cutting, shaping, and machining tools. The durability of tool steel surpasses that of spring steel in abrasive environments, while spring steel excels in resilience under dynamic loads.

Cost Considerations and Availability

Spring steel generally offers lower material costs and greater availability due to widespread production and simpler alloy compositions compared to tool steel. Tool steel tends to be more expensive because of its alloying elements like tungsten, molybdenum, and vanadium, which enhance hardness and wear resistance but increase cost and limit supply. Procurement decisions often balance spring steel's cost-effectiveness and accessibility against tool steel's superior durability and performance in demanding applications.

Selecting the Right Steel for Your Project

Spring steel offers exceptional elasticity and fatigue resistance, making it ideal for components requiring high flexibility and repeated stress endurance, such as springs and clips. Tool steel, known for its hardness, wear resistance, and heat tolerance, suits applications demanding precision and durability, like cutting tools and dies. Selecting the right steel hinges on balancing mechanical properties with project requirements, prioritizing factors like load type, environmental conditions, and operational temperature.

Summary: Spring Steel vs Tool Steel

Spring steel is characterized by its high yield strength and excellent elasticity, making it ideal for applications requiring flexibility and fatigue resistance such as springs and clips. Tool steel is designed for hardness, wear resistance, and ability to retain a sharp edge, commonly used in cutting, molding, and stamping tools. Selecting between spring steel and tool steel depends on the required mechanical properties, with spring steel prioritized for elasticity and tool steel favored for durability and hardness.

Spring Steel vs Tool Steel Infographic

materialdif.com

materialdif.com